4.8 How the MT Controller Works

Mold-Masters controllers are designed to perform in closed and open loop

congurations. We consider that the normal operating mode is closed loop.

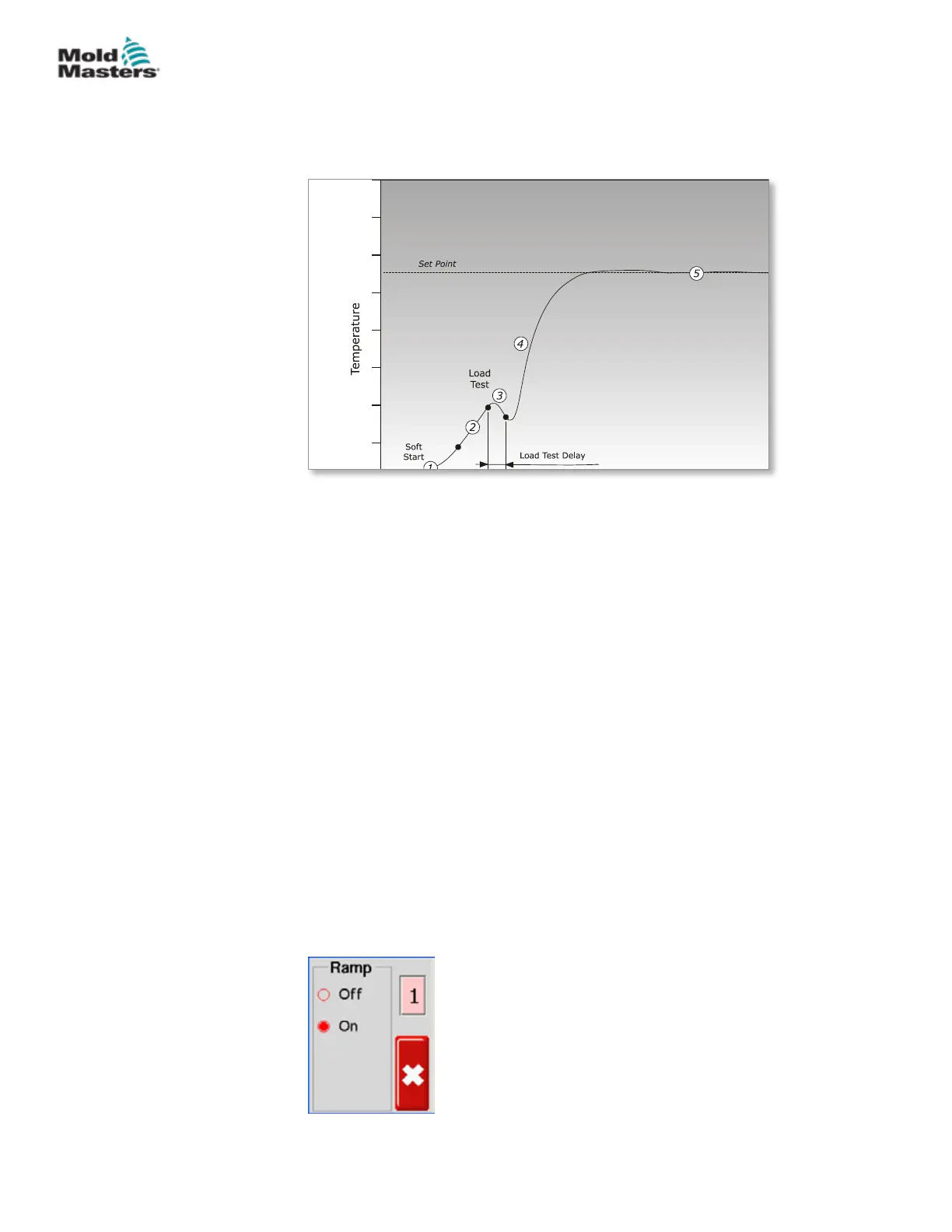

This is illustrated in the following diagram and explained below.

The zone controller slowly ramps up the heater power and simultaneously

looks for a positive temperature change at the thermocouple input. The

controller veries the actual rate of rise against a predetermined value in

program parameter r1. Power is slowly increased until the correct rate of rise

is achieved.

At ramp temperature rE, the dwell time rt is activated (2 minutes), this permits

any residual moisture in the heating elements to be eliminated. After all zones

reached to ramp temperature, they will start heating up together again.

The controller continues to ramp up the temperature to the set point with the

speed set in program parameter r2, which should be achieved with minimum

overshoot.

Having built a virtual model to map the tool and heater characteristics, the

controller can maintain the temperature at an accurate point with virtually no

deviation.

4.8.1 Set the Ramp Feature (On / Off)

Normally the controller starts to heat a zone and then it pauses at around

120° C for two minutes to dry out any damp that may be present.

If you prefer not to wait for this dwell period then you can use the “Ramp”

feature to skip the delay period to reach molding temperature more quickly.

See page 5-9 for full description.

4-6

© 2020 Mold-Masters (2007) Limited. All Rights Reserved.

OVERVIEW

MT Controller User Manual

Loading...

Loading...