10

Maintenance of the Saw Chain and

Guide Bar

SAW CHAIN

WARNING!

It is very important for smooth and safe operation to

always keep the cutters sharp.

Your chain saw cutters need to be sharpened when.

• Sawdust becomes powder like.

• You need extra force to saw.

• The cut way does not go straight.

• Vibration increases.

• Fuel consumption increases.

Cutter setting standards.

WARNING!

Be sure to wear safety gloves when servicing.

Before filing:

• Make sure the saw chain is held securely.

• Make sure the engine is stopped and the spark plug dis-

connected.

• Use a round file of proper size for your chain.

Model MCS25 Chain File size: 5/32” (4.0 mm)

Model MCS38 Chain File size: 5/32” (4.0 mm)

Model MCS45 Chain File size: 3/16 ” (4.76 mm)

Model MCS52 Chain File size: 3/16 ” (4.76 mm)

Model YR4503 Chain File size: 3/16 ” (4.76 mm)

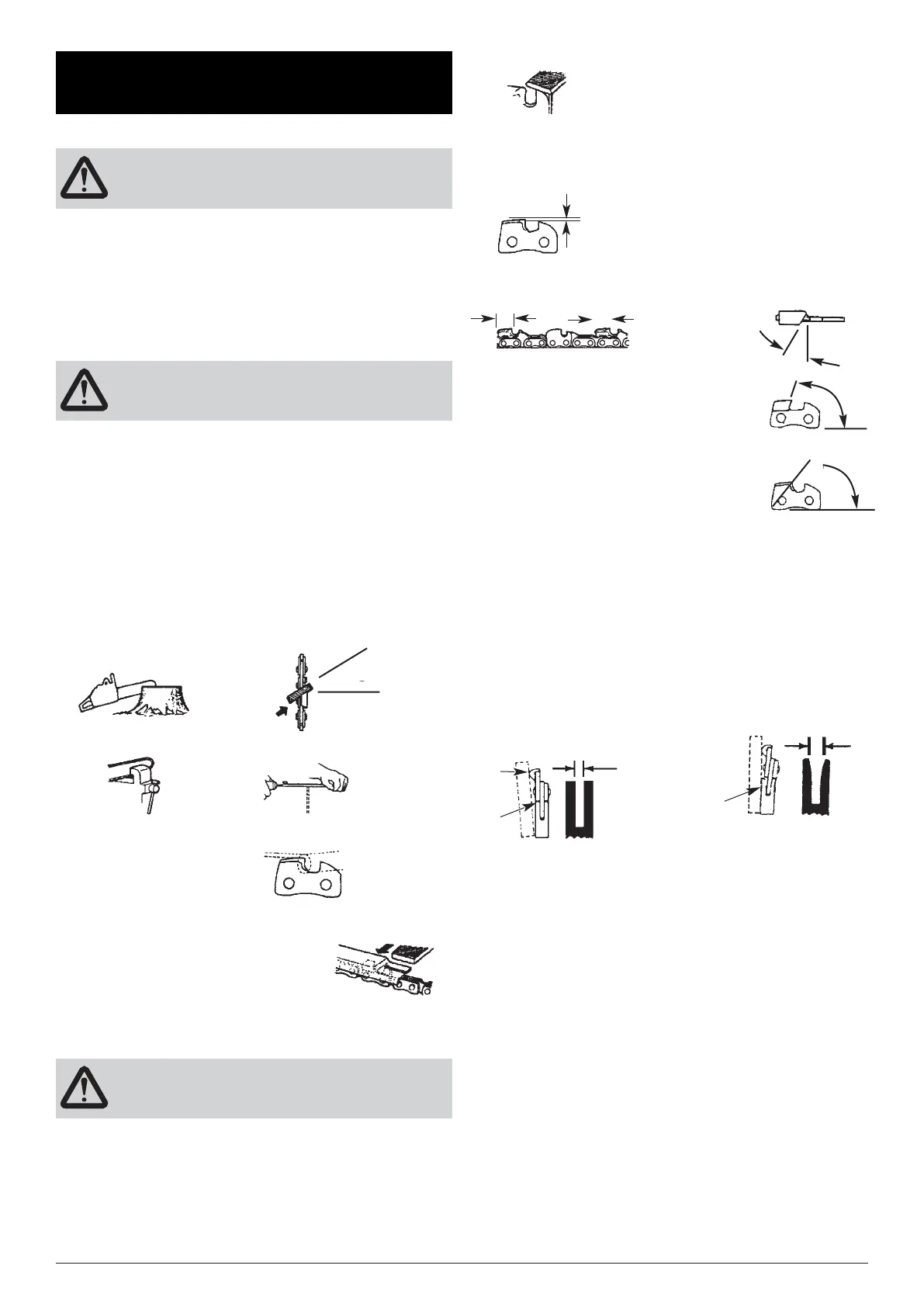

30˚

90˚

20˚

Fix chain so it can not move.

• Place your file on the cutter and

push straight forward. Keep the file

positioned as illustrated.

• After every cutter has been set,

check the depth gauge and file it to

the proper level.

WARNING!

Be sure to round off the front edge to reduce the chance of

kickback or tiestrap breakage.

Appropriate gauge checker.

Make shoulder rounded.

Make sure every cutter has the same length and edge angles

as illustrated.

Depth gauge standard.

x

x

Cutter length Filing angle

Side plate angle

Top plate angle

30˚

85˚

60˚

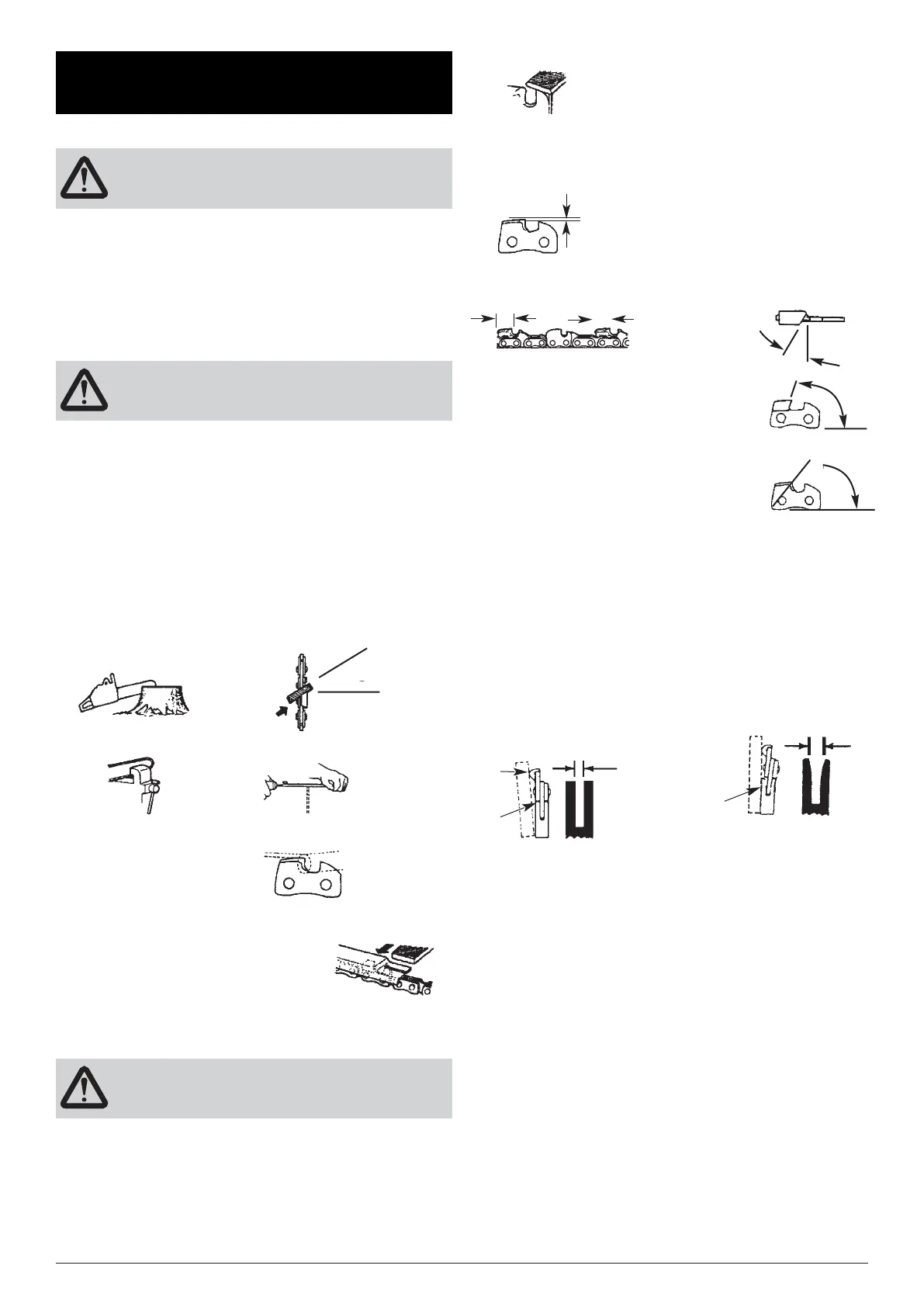

GUIDE BAR

• Flip the bar upside down occasionally to promote even

wear.

• The bar rail should always be a square. Check for wear of

the bar rail. Apply a ruler to the bar and the outside of a

cutter. If a gap is observed between them– the rail is nor-

mal.

Good guide bar

Rul-

er

Gap

Guide bar rail

Guide bar needs replacing

No gap. Chain should not move

sideways in the guide rail

Guide bar rail

worn

Loading...

Loading...