9

WARNING!

•Always ensure your footing. Do not stand on the log.

•Be alert to the rolling over of a cut log. Especially when

working on a slope, stand on the uphill side of the log.

•Follow the instructions in ‘Safe Operation’ to avoid kickback

of the saw.

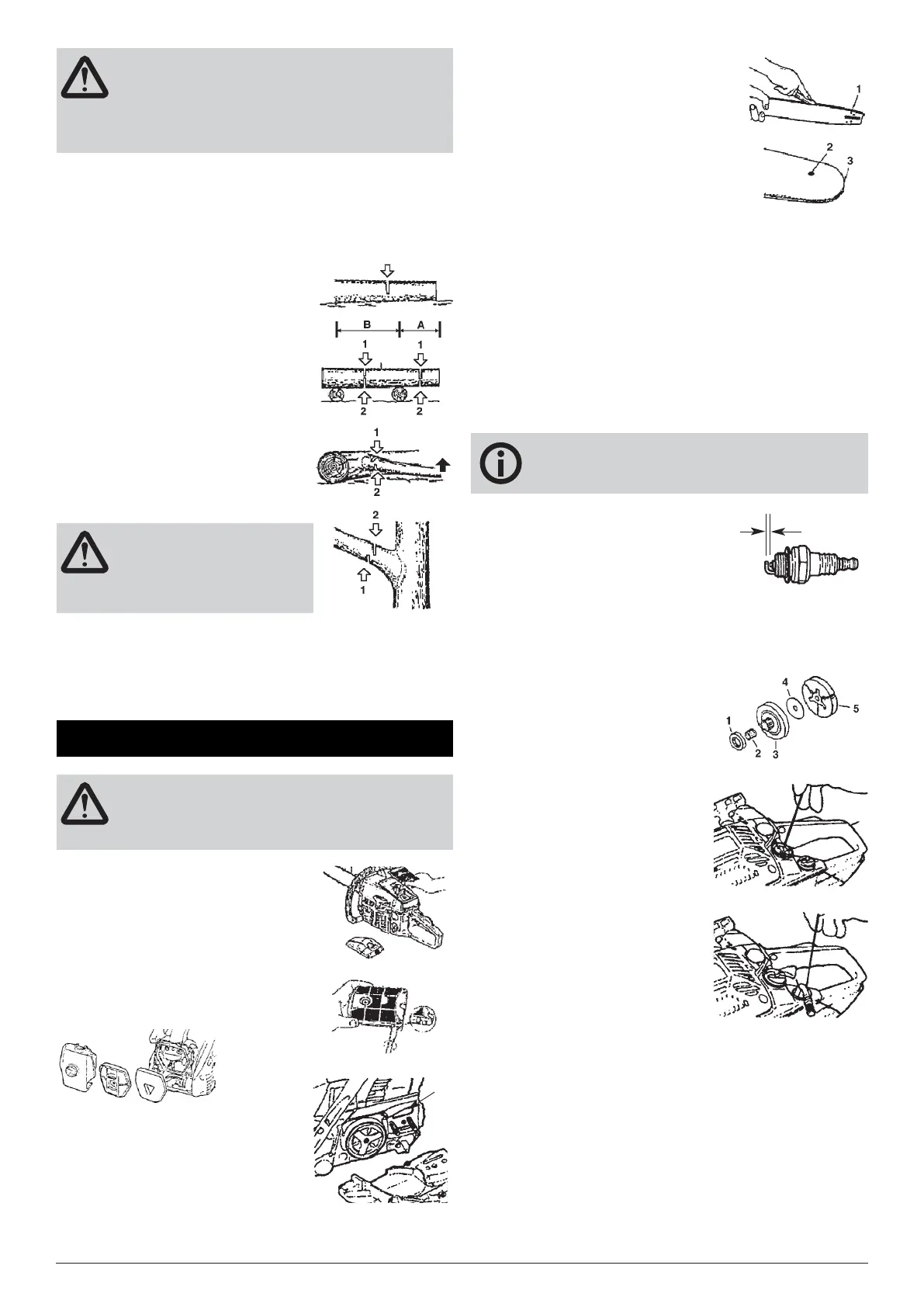

Before starting work, check the direction of bending force

inside the log to be cut. Always finish cutting from the

oposite side of bending direction to prevent the guide bar

from being jammed in the cut.

Cutting a log lying on the ground.

Saw down halfway,then roll the log over

and cut from the opposite side.

Cutting a log hanging off the ground.

In area ‘A’ saw up from the bottom one

third and finish by sawing down from

the top. In area ‘B’ saw down from the

top one third and finish by sawing up

from the bottom

Cutting a limb of fallen tree.

First check to which side the limb is

bent. Then make the initial cut from the

bent side and finish by sawing from the

opposite side.

WARNING!

Be alert to the springing back of a

cut limb. Pruning of Standing Tree.

Cut up from the bottom, finish down

from the top.

• Do not use an unstable foothold or ladder.

• Do not overreach.

• Do not cut above shoulder height.

• Always use your both hands to grip the saw.

Maintenance

WARNING!

Before cleaning, inspecting, or repairing your unit, make sure

the engine has stopped and is cool. Disconnect the spark

plug to prevent accidental starting.

MAINTENANCE AFTER EACH USE

1. Air filter

Dust on the cleaner surface can be

removed by tapping a corner of the

cleaner against a hard surface. To

clean dirt in the meshes, split the

cleaner into halves and brush with

gasoline. When using compressed air,

blow from the inside.

2. Oiling port

Dismount the guide bar and check

the oiling port for clogging.

Oil Port

3. Guide bar.

When the guide bar is dismounted,

remove sawdust in the bar groove and

the oiling port. Grease the nose sprocket

from the feeding port on the tip of the bar.

4. General Maintenance.

Check for fuel leakage, loose fastenings and damage to ma-

jor parts. Especially handle joints and guide bar mounting.

If any defects are found, make sure to have them repaired

before operating the machine again.

PERIODICAL SERVICE CHECKS

1. Cylinder fins.

Dust clogging between the cylinder fins will cause overheat-

ing of the engine. Periodically check and clean the cylinder

fins after removing the air cleaner and the cylinder cover.

When installing the cylinder cover, make sure that switch

wires and grommets are positioned correctly in place.

IMPORTANT!

Be sure to cover the air intake hole whilst cleaning.

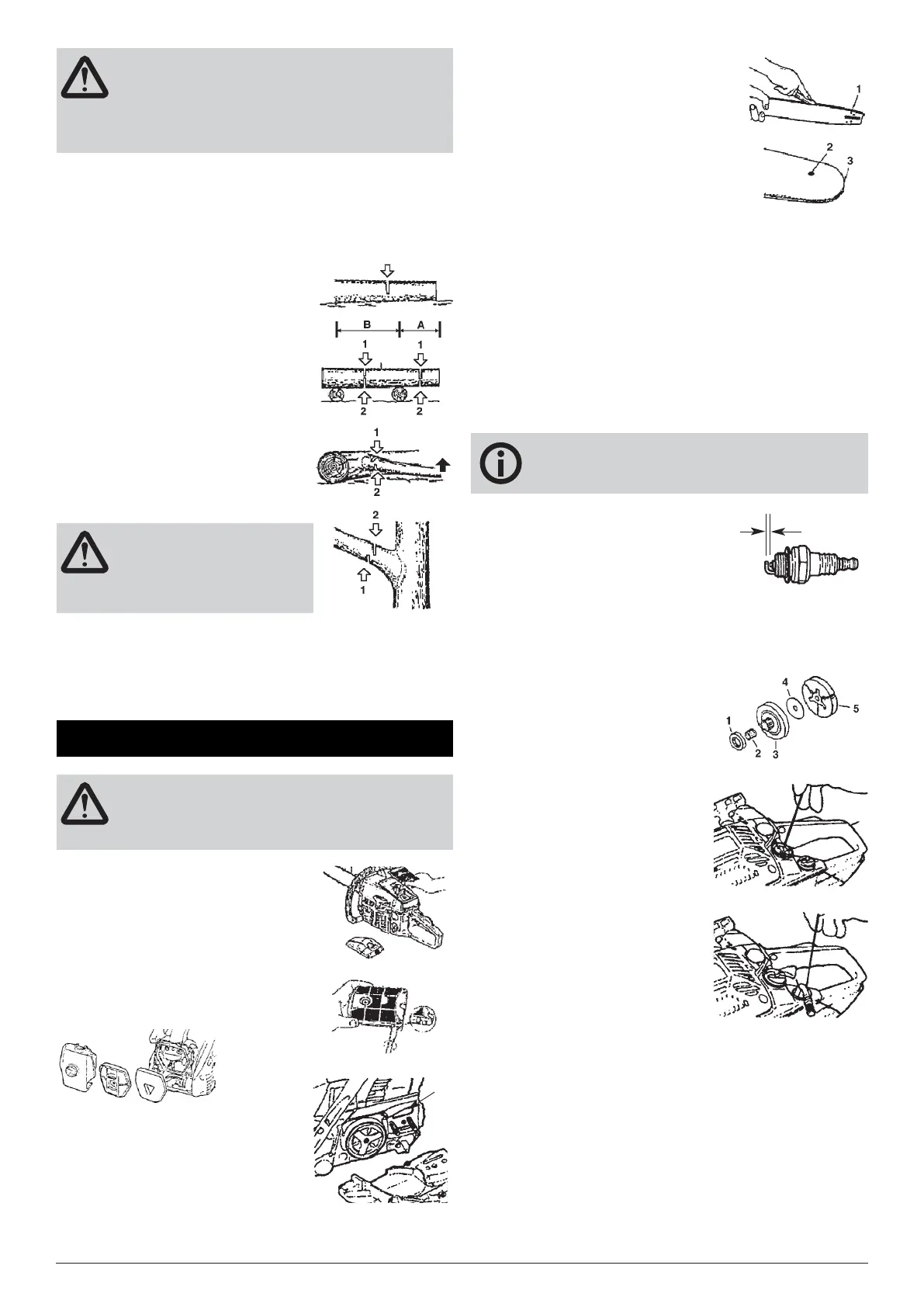

2. Spark plug.

Clean the electrodes with a wire brush

and reset the gap to 0.65mm as

necessary

3. Sprocket.

Check for cracks and for excessive wear interfering with the

chain drive. If wear is obvious, replace it with new one. Never

fit a new chain on a worn sprocket, or a worn chain on a new

sprocket.

1. Sprocket

2. Needle bearing

3. Clutch drum

4. Spacer

5. Clutch shoe

4. Fuel filter (MCS38 shown).

Disassemble the filter and wash with

gasoline, or replace with new one if

needed.

5. Oil filter (MCS38 shown).

Disassemble the oil filter and

wash with gasoline, or replace

with new one if needed.

6. Anti-vibration system

All models have rubber bumpers,

have your dealer replace them should

they show signs of cracking or damage.

1. Oiling port

2. Grease port

3. Sprocket

0.65mm

Loading...

Loading...