Page 24

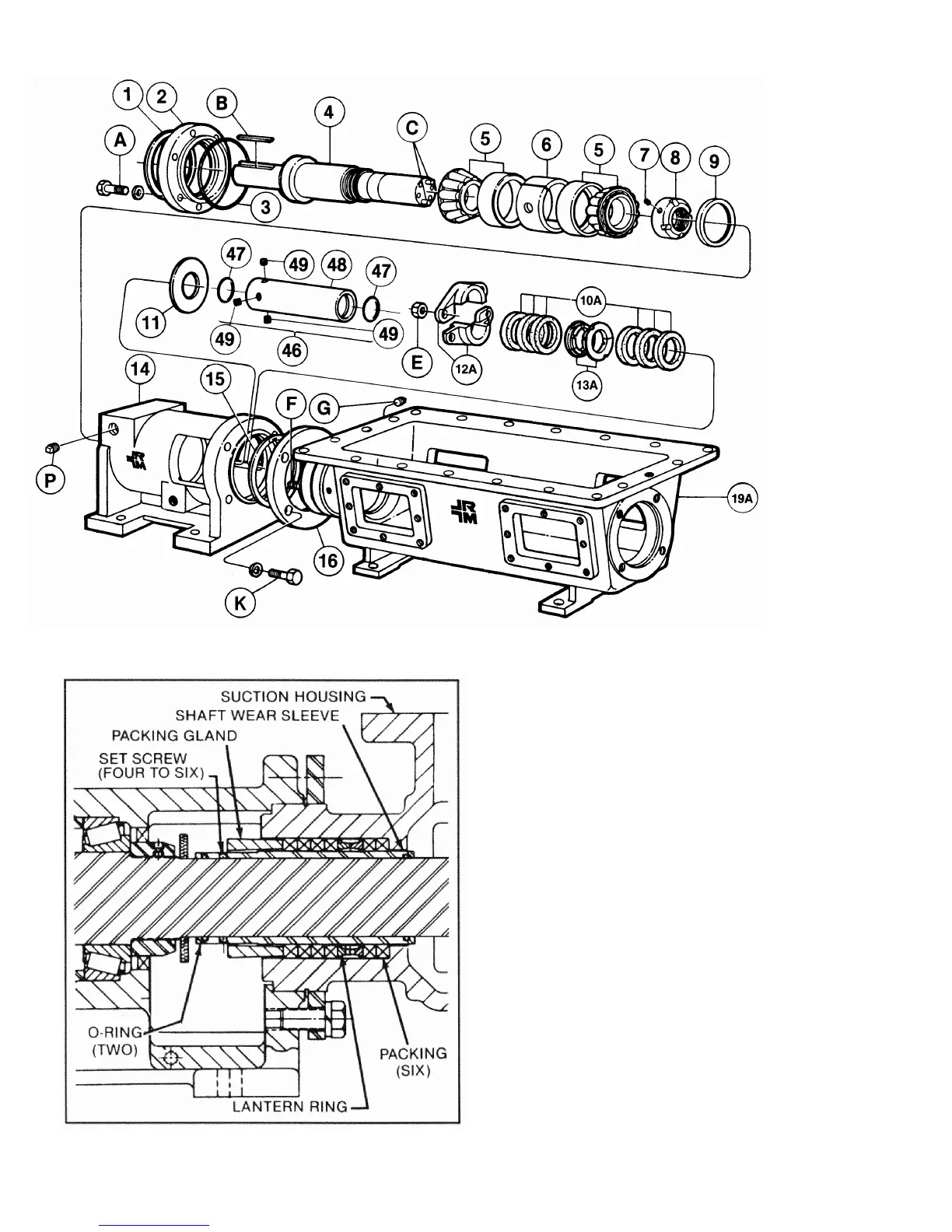

4-64. SHAFT SLEEVE ARRANGEMENT

Some pumps have a sleeve installed on the drive shaft to

receive any possible wear caused by the packing. See

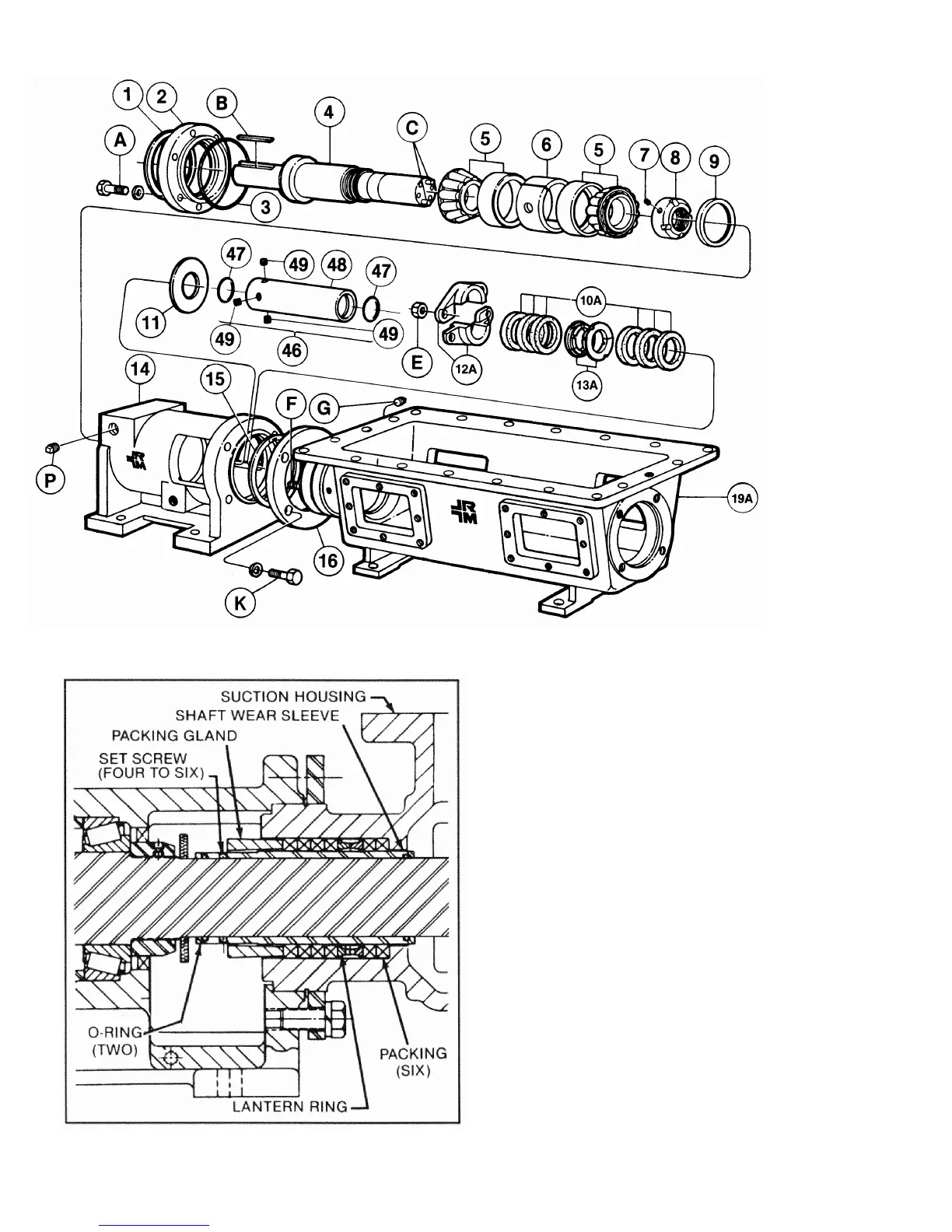

sleeve kit (46, fig. 4-11), and the cross section illustration

(fig. 4-12).

4-65. Disassembly (see fig. 4-11). After separation of bear-

ing housing (14) from suction housing (19A), and removal of

packing gland and packings, remove sleeve as follows:

1. Loosen four to six set screws (49) in sleeve (48),

and pull sleeve off shaft (4).

2. Remove two O-rings (47) from interior of sleeve.

4-66. Assembly. Assemble pump to the point where slinger

ring (11) is installed on drive shaft (4), then install sleeve kit

(46) as follows.

1. Lubricate two O-rings (47) and insert in grooves in inte-

rior of sleeve (48). Loosely install four to six set screws (49)

in sleeve, but be sure they do not protrude into interior of

sleeve.

2. Install sleeve unit (47, 48, 49) over drive shaft (4) so

that set-screw end of sleeve is in toward slinger ring (11).

3. Adjust sleeve to be flush with end of drive shaft, and

tighten the four to six set screws (49).

Figure 4-11. Shaft Sleeve Arrangement

Figure 4-12. Pump with Shaft Wear Sleeve

Loading...

Loading...