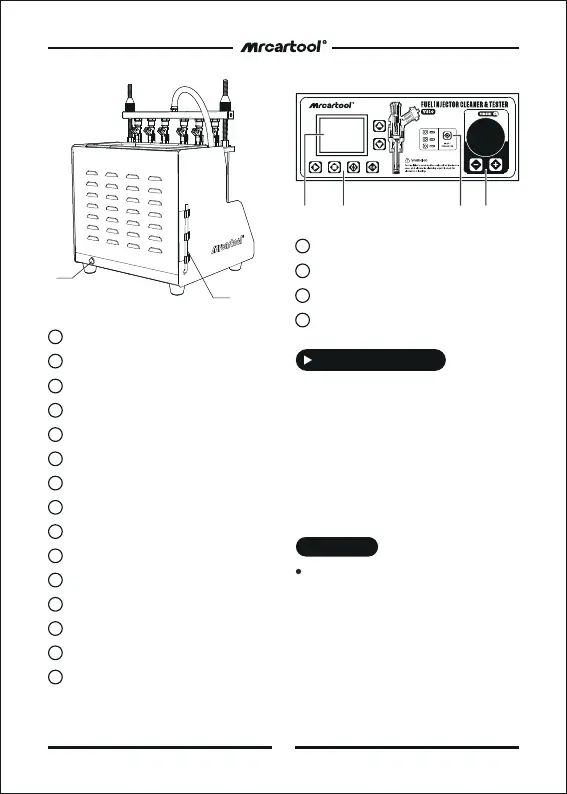

Lock pole;1

Lock nut;

2

Top oil inlet connector;

4

Glass measuring cylinder;

5

Oil drain handle;

6

Operation panel;

7

Pressure gauge;

8

Oil outlet pipe;

9

Ultrasonic cleaning tank;

10

Signal wire;

11

Power switch;

12

Power socket;

13

Cleaning agent drain valve;

14

Testing agent liquid level

15

Oil rail;

3

3

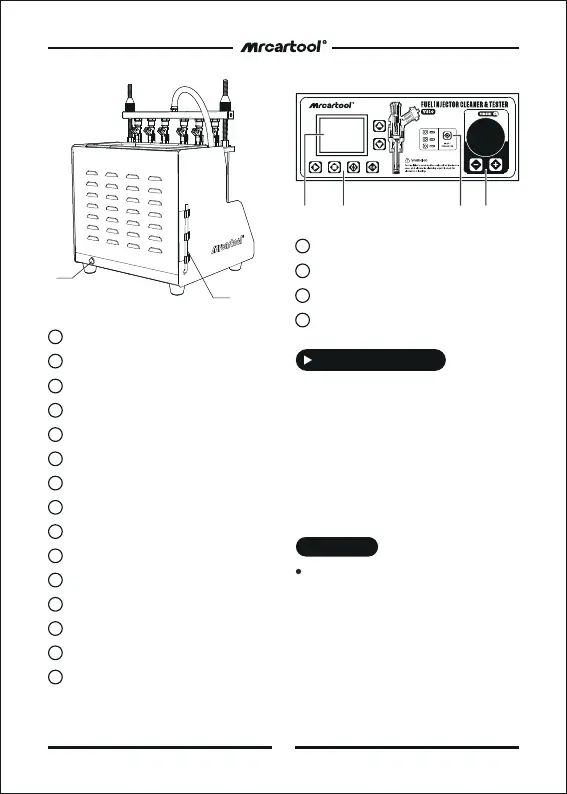

2.2 Operation Panel Diagram

⑭

⑮

TFT color screen;

1

Function buttons;

2

Pressure adjustment;

4

Voltage selection of injectors;

3

① ② ③ ④

Ultrasonic cleaning is to use the

penetrating and cavitation shock

waves generated when ultrasonic

waves propagate in the medium, and

powerfully clean objects with complex

shapes, cavities and pores to

completely remove stubborn carbon

deposits on the fuel injector.

Operation Process

3.1 Ultrasonic Cleaning

Remove the fuel injector from the

vehicle and check whether its rubber

seal is damaged. If it is damaged, it

should be replaced in time before the

cleaning test to avoid leakage during

the test. Then put the fuel injection

nozzle into the cleaning agent,

carefully remove the external grease

and wipe it with a soft cloth.

Preparation

Loading...

Loading...