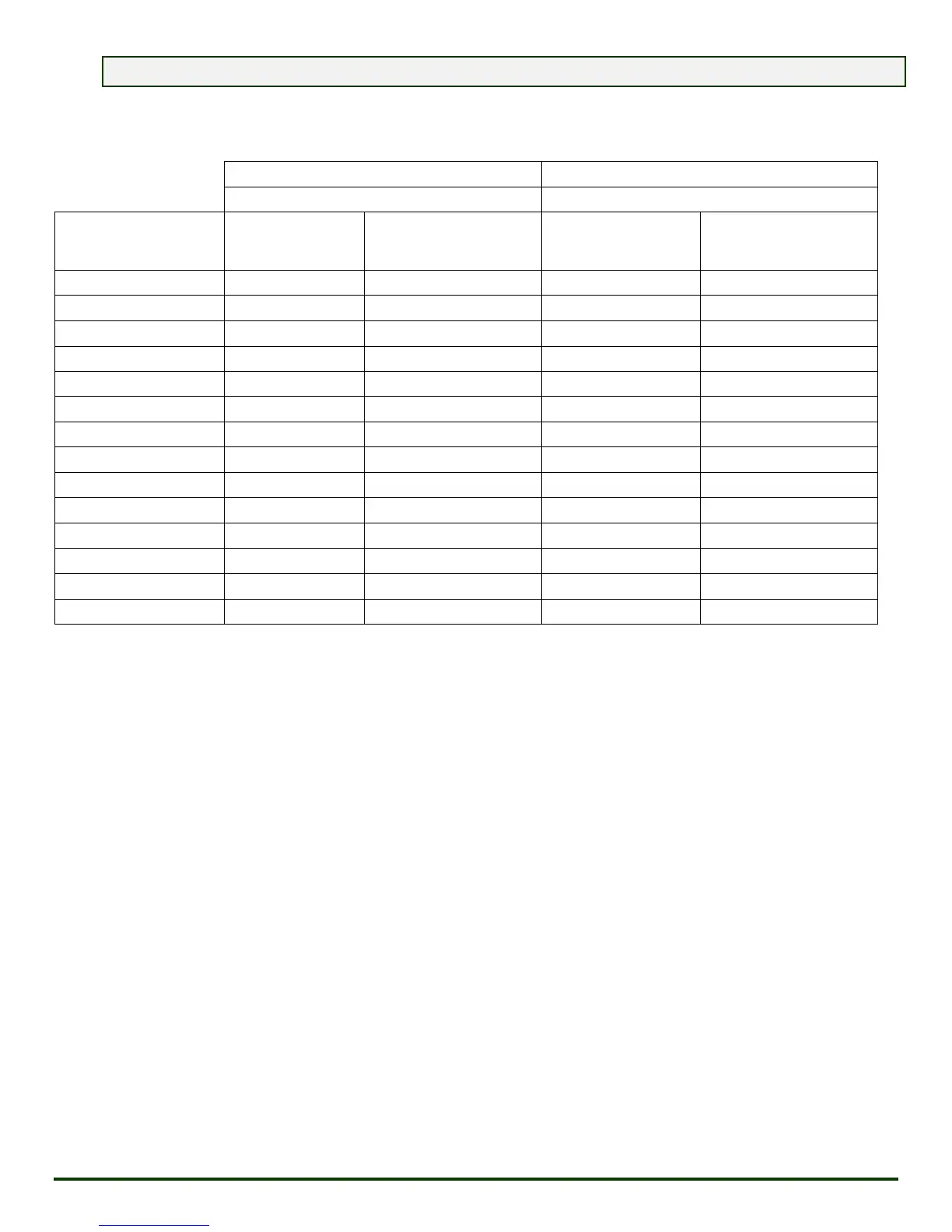

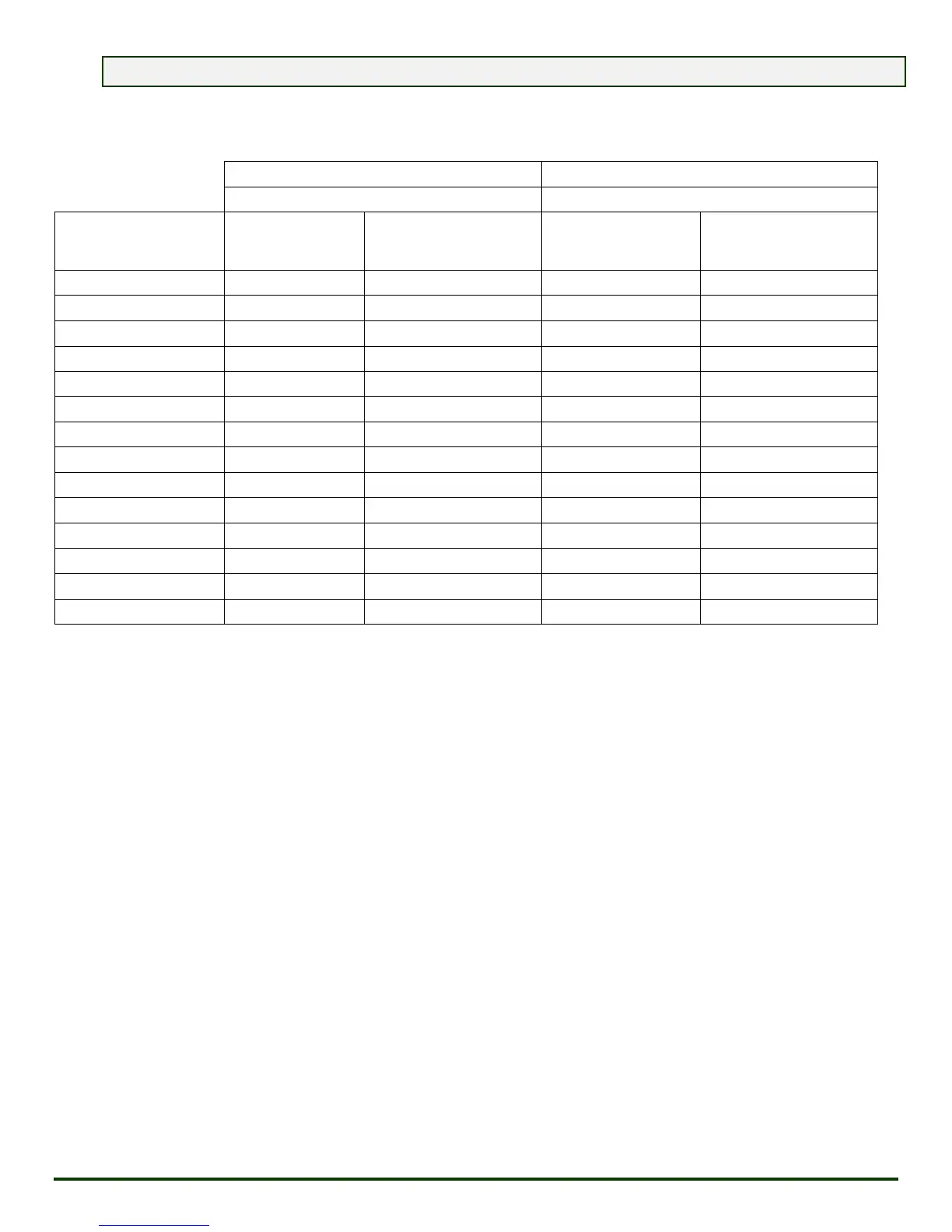

Appendix C FASTENER TORQUE DATA

GENERAL TORQUE TABLE

Thread Diameter

& Thread Pitch

Dry Threads

Torque (ft*lbs)

Lubricated Threads

Torque (ft*lbs)

Dry Threads

Torque (ft*lbs)

Lubricated Threads

Torque (ft*lbs)

**Specific Installation Torques**

Connecting Rod Cap Nuts: Install 5/8”-11 castellated nuts using Loctite® Threadlocker Blue and torque to

150 ft-lbs of torque.

Connecting Rod Pin Screws: Install 3/8”-16 screws using Loctite® Threadlocker Blue and torque to 40 ft-lbs

of torque.

Crosshead Slide Screws: Install 5/8”-11 screws using Loctite® Threadlocker Blue and torque to 50 ft-lbs of

torque.

Fluid End Plungers: Install plungers using anti-seize compound and torque to 375 ft-lbs of torque.

Power End Plunger Screws: Install 1/2”-13 screws using Loctite® Threadlocker Blue and torque to 75 ft-lbs

of torque.

MSI - A Division of Dixie Iron Works, Ltd. All rights reserved.

Loading...

Loading...