MUELLER

®

B-101

TM

and B-100

TM

Drilling and Tapping Machines

Operating Instructions

11

properly engage. It is very likely it

will be necessary to slightly shift the

machine during this operation to get

proper alignment.

17. As soon as boring bar is

permanently attached to extracting

tool, chain hook nuts can be

tightened. Considerable caution is

required to bring the machine down

evenly on the pipe. If machine is

tightened down unevenly a strain will

be placed on boring bar and if old

corporation stop or plug is removed

under these conditions, the new one

will not start in the old hole.

15. Slowly move boring bar

downward to engage left hand

thread of extracting tool shank with

mating thread in nut part attached

to corporation stop or plug. Attach

ratchet handle to boring bar and

adjust ratchet for counter-clockwise

rotation.

16. As soon as the extracting tool

shank contacts the nut part on

corporation stop or plug, slowly

rotate the ratchet handle counter-

clockwise to engage the left hand

threads. This is a very sensitive

operation and extreme caution

must be taken to be sure threads

18. Push bypass valve to “bypass”

position and rotate ratchet handle

counter-clockwise to extract the

stop or plug. Raise boring bar to

upper position as soon as old stop or

plug becomes disengaged from main.

19. Close flop valve and pull bypass

valve to “relieve” position.

20. Proceed with the use of

the machine following previous

instructions.

3. Attach a length of hose to the

blow-off valve outlet. Valve outlet is

3

/4” National Hose Thread (regular

garden hose coupling size). (S.)

4. When starting to drill and tap the

main, open the valve. Main pressure

will flush the chips out through the

hose outlet.

5. Close the valve after the tapping

operation has been completed.

NOTE: The tapping machine body

has a boss with

1

/2” I.P. tapping

and is shipped with a brass plug

installed. A blow-off valve is also

shipped with each machine. The

blow-off valve provides a means

to prevent pipe chips and other

drilling and tapping residue from

entering the main during pressure

taps.

To properly use the blow-off valve,

follow these instructions:

1. Remove the brass plug from the

boss of machine body.

2. Apply non-hardening dope to the

inlet threads of the blow-off valve

and install the valve in the tapped

boss of machine body. The valve

should be tightened sufficiently to

provide a pressure tight joint and

then positioned so that the valve

key does not interfere with the pipe

saddle.

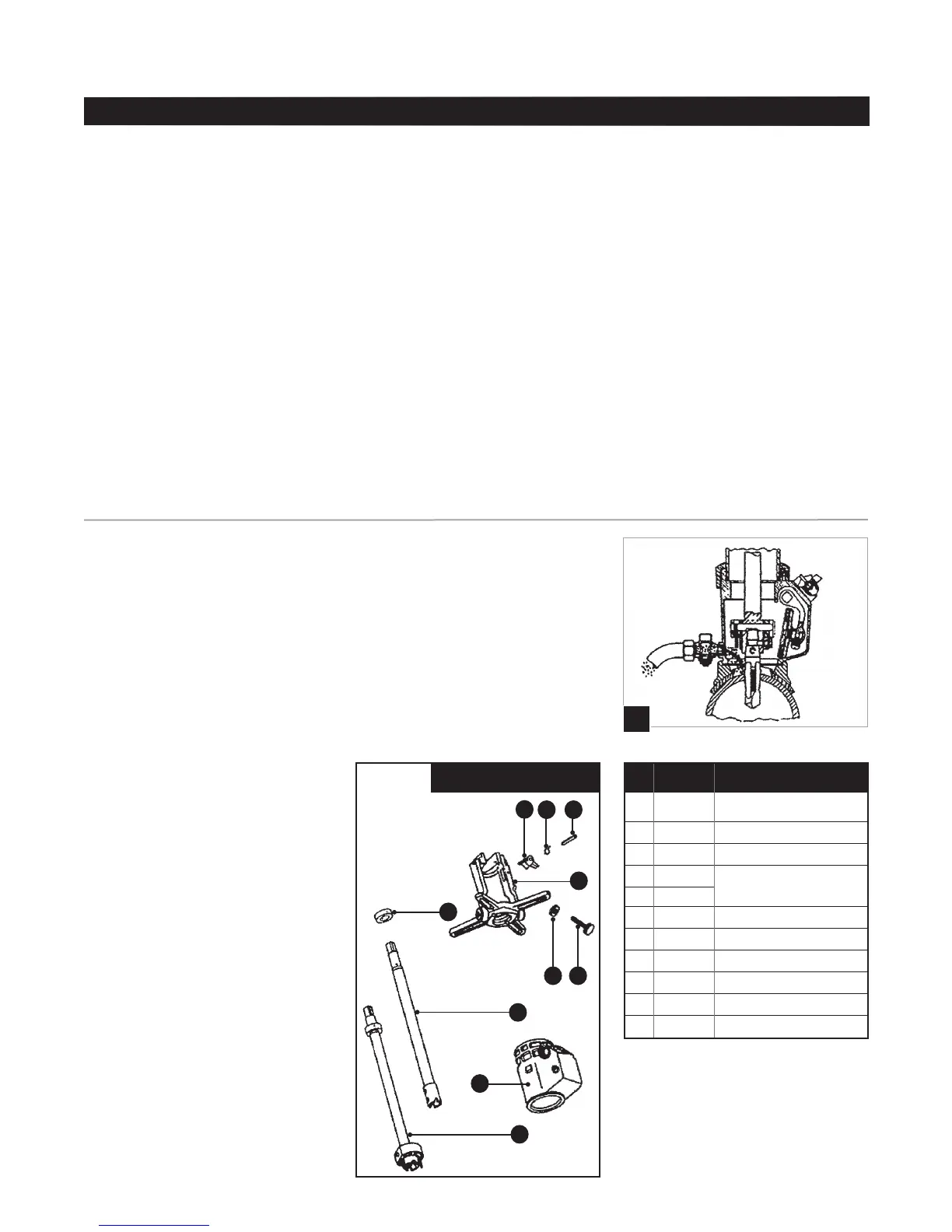

Blow-o Valve Operating Instructions

S.

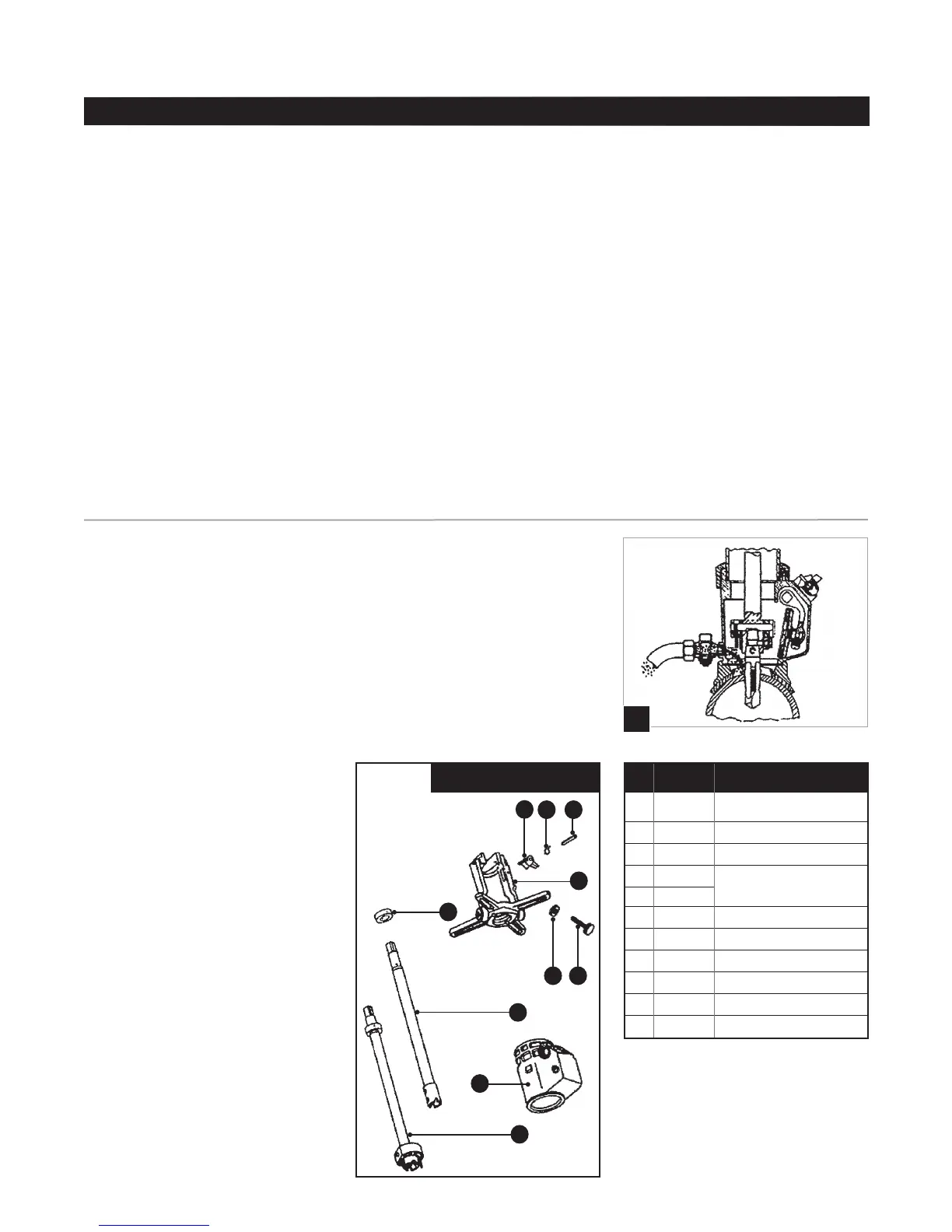

1 502025 Pivot Arm

2 502026 Pivot Arm Spring

3 502027 Roll Pin

4 580611 Feed Nut & Yoke

Complete

5 502029 Lock Nut

6 502028

Operating Screw

7 580610 Friction Collar

8 502022 Boring Bar

9 502046 Valve Body

10 581286 Boring Bar Complete

4

7

5 6

8

9

10

2

1

3

NOTE: Parts for the B-101

machine are the same as the

B-100 machine except for the

parts shown here.

Loading...

Loading...