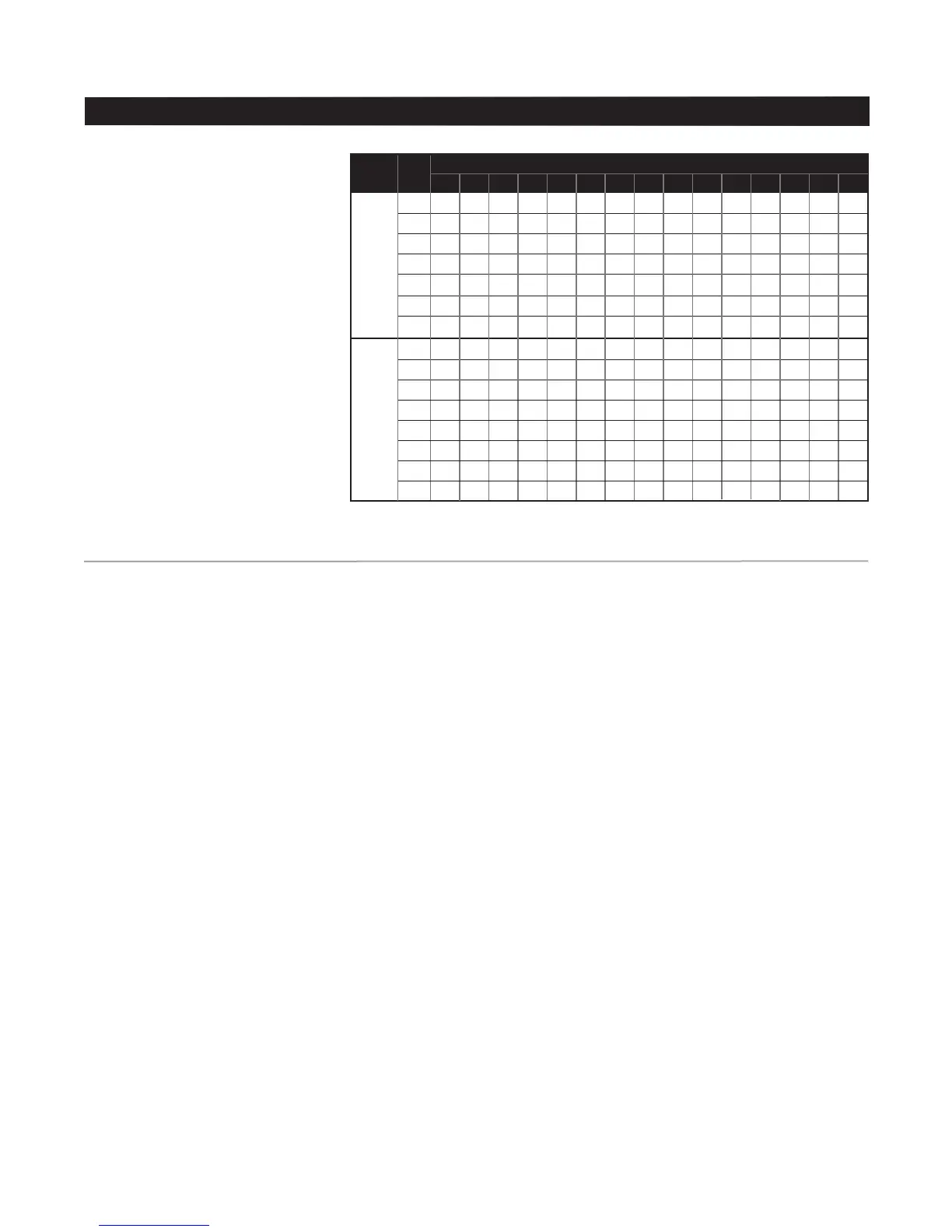

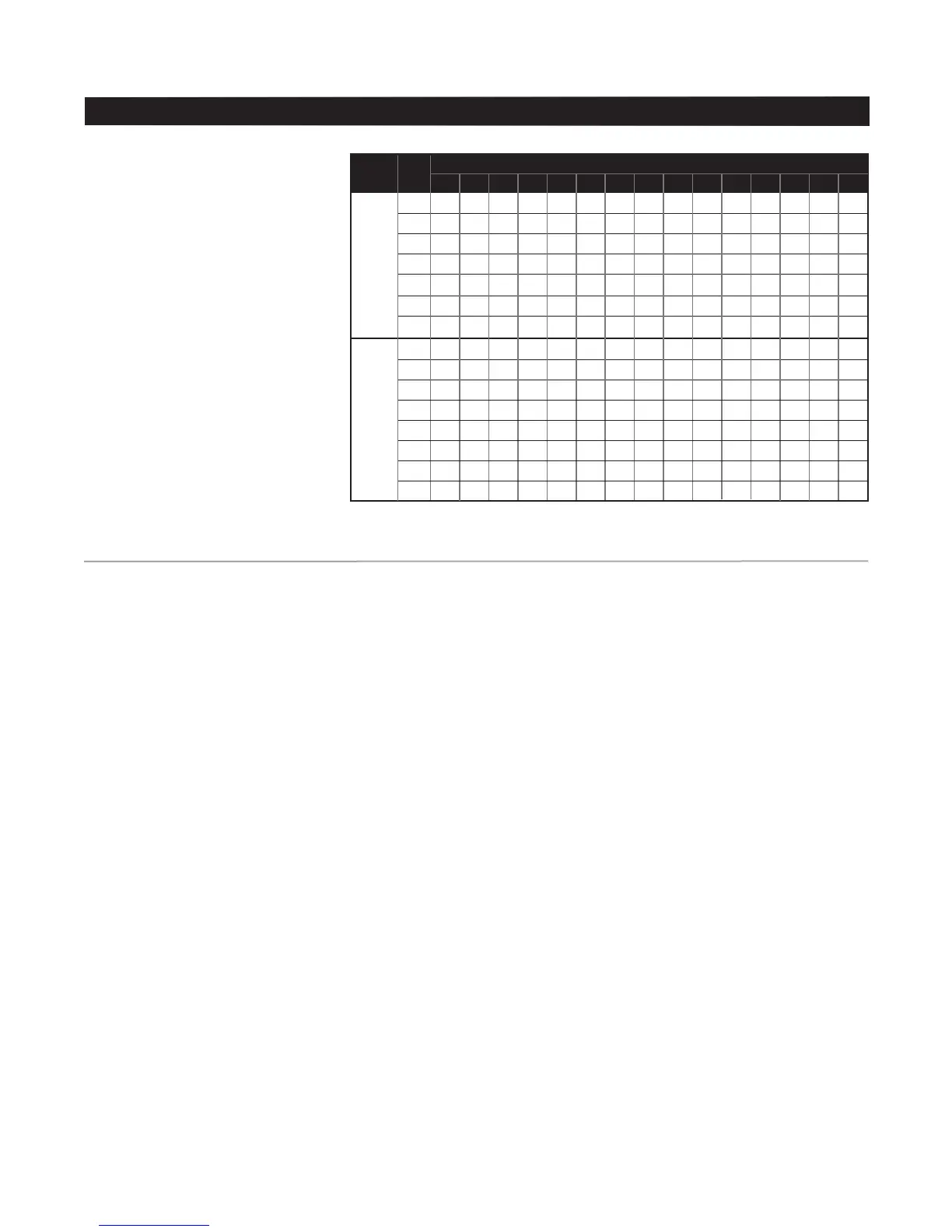

Thickness of Pipe Wall

This chart (right) gives the minimum

wall thickness of pipe that will

provide the recommended four full

threads of engagement with the

corporation stop inlet thread. For

pipe with thinner walls than specied

here, use Mueller Service Clamps

and Corporation Stops.

MUELLER

®

B-101

TM

and B-100

TM

Drilling and Tapping Machines

Maintenance Instructions

3

After Use

Thoroughly clean the entire machine

and all tools, and lubricate all

machined surfaces.

Remove all chips from inside the

body including the op valve recess.

A special body-cleaning chisel is

furnished for this purpose. If chips

are permitted to accumulate in

the machine, they could rust and

become caked and interfere with the

operation of the op valve.

NOTE: DO NOT bump machine on

hard surface to shake chips out

of body. Saddle gasket surface

is damaged by this type of

operation.

The machine and all tools and

equipment should be stored in the

machine chest. Carefully place tools

in their individual compartments to

prevent damage to the cutting edges.

Boring Bar Packing

Machine is equipped with O-ring

packings, which are nonadjustable.

When leakage occurs, replacement

is necessary.

NOTICE: The machine used to

illustrate this manual may differ

somewhat in appearance from

currently produced machines.

If one of these differences is of

signicance, it will be referred to

in the instructions.

Before Use

Clean and lubricate all wearing

and bearing surfaces and threads

EXCEPT the boring bar thrust collar

which requires no lubrication.

NOTE: If lubricated, service life

of boring bar thrust collar may be

shortened.

Boring bar is lubricated between

upper and lower O-ring seal in

feed sleeve and cap by a reservoir

containing light machine oil. Remove

oil plug in feed sleeve near lower

end and occasionally ll with light oil.

Inspect and clean all tools,

particularly the shank ends, and

remove any burrs or scale, which

would prevent proper alignment with

the boring bar.

Inspect and clean the socket in the

end of the boring bar and remove any

burrs or scale which would prevent

the tool from seating properly.

These packings are replaced in the

following manner:

1. Remove ratchet handle and feed

nut and yoke from boring bar.

2. Punch out boring bar thrust collar

retaining pin. Slide collar off bar.

3. Unscrew feed sleeve and cap

from cylinder and slide feed sleeve

and cap off bar.

4. Remove wiper ring and O-rings

from recess in top and bottom of

feed sleeve and cap.

5. Check wiper ring and O-ring

packing recesses to be sure they

are clean before placing new rings in

these grooves. New wiper ring and

O-ring packings should be lubricated

with machine oil or light grease

before they are placed in the feed

sleeve and cap.

6. Be sure the top end of boring

bar at squared end has no rough

edges or burrs that would damage

the new wiper ring and O-ring

packings as the feed sleeve and

cap are replaced on the boring bar.

Screw feed sleeve and cap back on

cylinder.

Tools and saddles are offered for

use with cast iron, ductile iron, steel

and asbestos-cement pipe in sizes

from 2” to 48”.

Maximum Working Pressure

90psi without power clevis

250psi with power clevis

1

/2” .33 .32 .31 .30 .30 .30 .30 .29 .29 .29 .29 .29 .29 .28 .28

5

/8” .36 .35 .32 .31 .31 .30 .30 .30 .29 .29 .29 .29 .29 .29 .28

3

/4” .37 .36 .35 .34 .33 .33 .32 .32 .32 .32 .31 .31 .31 .31 .31

1” .46 .44 .40 .39 .38 .37 .36 .36 .36 .35 .35 .35 .34 .34 .34

1

1

/4” .57 .52 .47 .44 .42 .41 .49 .39 .39 .39 .38 .37 .37 .37 .37

1

1

/2” .64 .58 .51 .47 .45 .43 .42 .41 .40 .40 .39 .38 .38 .37 .37

2” .86 .75 .61 .55 .51 .48 .46 .45 .44 .43 .42 .40 .40 .39 .38

1

/2” .330.322.311.305.301.299.297.296 .295.295.292 .291.290.289.289

3

/4” .356.343.325.316.310.306.304.301 .300.298.296 .294.293.292.291

1” .459.438.411.396.387.381.376.373 .370.368.365 .361.359.358.356

1

1

/4” .528.493.449.425.410 .400.393 .388 .383 .380 .375 .370 .366 .363.361

1

1

/2” .588.540.481.449 .430 .417 .407.400 .394.390.383 .376.372.368.366

2” .740.657.558.508.477.456.441.430 .421.414.403 .392.385.380.376

2

1

/2” — .968.812.736.689.658.636.620 .607.596.580 .565.554.546.541

3” — — .975.855.784.737.704.679 .659.644.620 .596.580.569.560

AWWA

Taper

Thread

AWWA

I.P.

Thread

Maintenance Instructions

Loading...

Loading...