!Caution

Inverting the PCB

Make sure not to impose any abnormal mechanical shocks to

the PCB.

4. Optimum Solder Amount for Reflow Soldering

4-1. Overly thick application of solder paste results in a

excessive solder fillet height.

This makes the chip more susceptible to mechanical

and thermal stress on the board and may cause the

chips to crack.

4-2. Too little solder paste results in a lack of adhesive

strength on the termination, which may result in

chips breaking loose from the PCB.

4-3. Please confirm that solder has been applied

smoothly to the termination.

<Applicable to NFM Series>

Continued from the preceding page.

Continued on the following page.

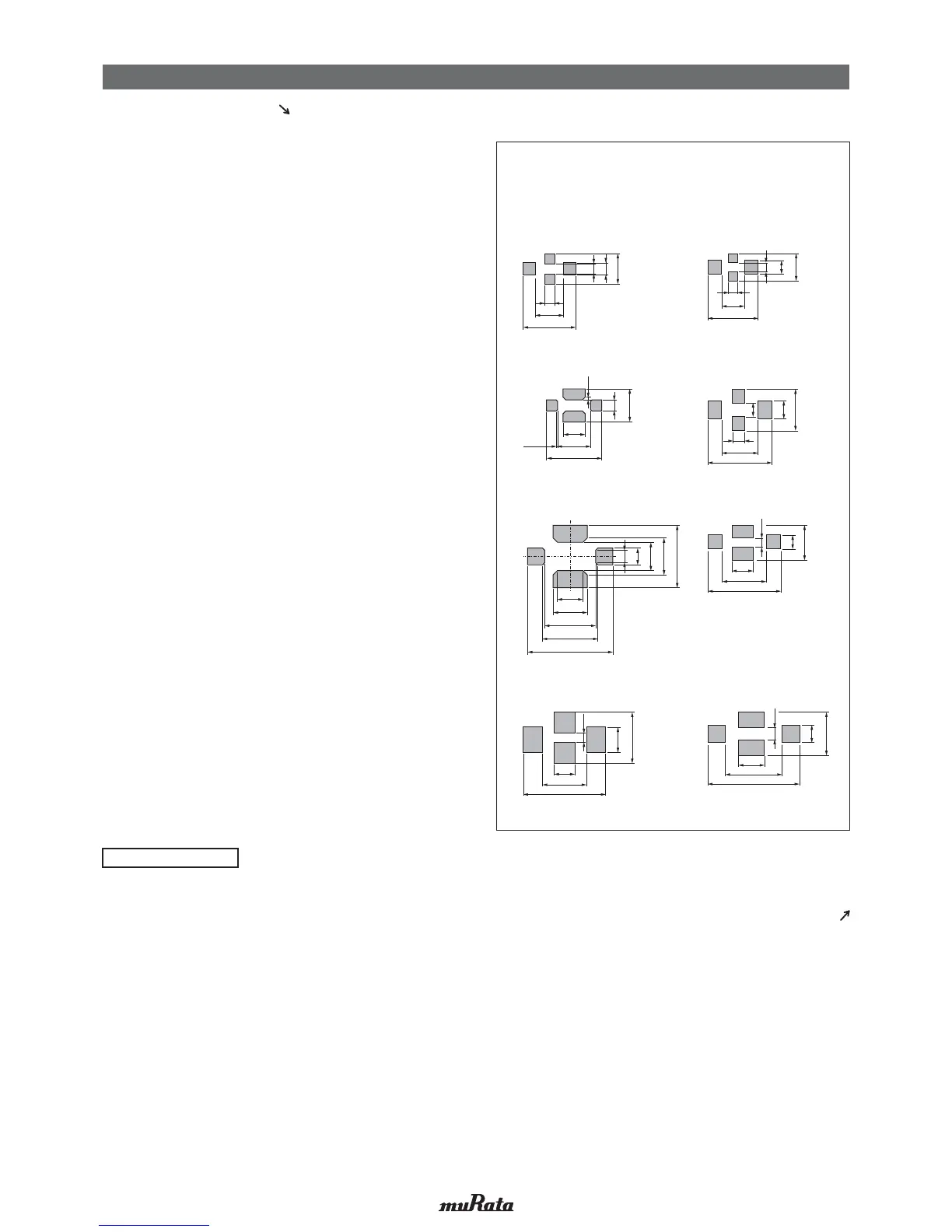

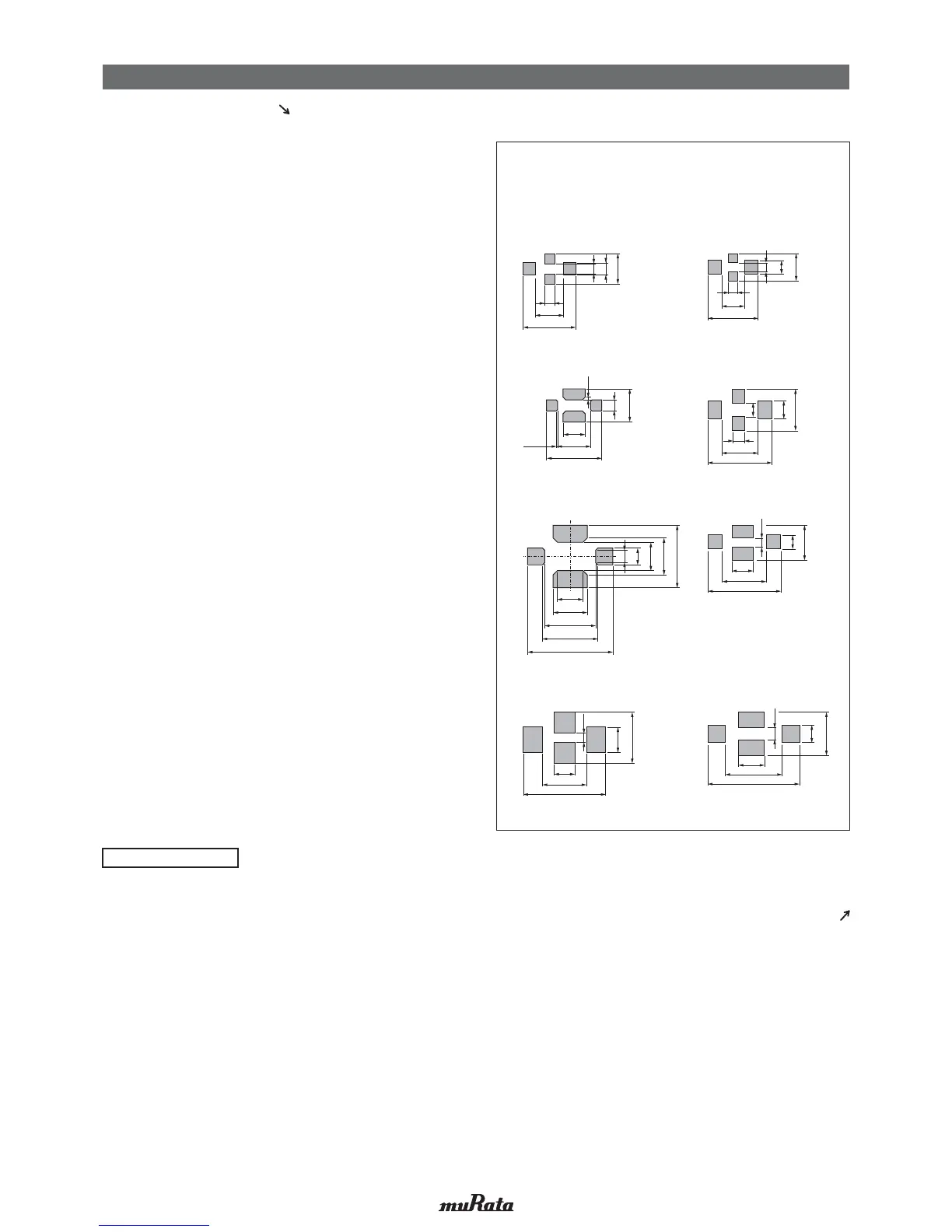

100-150μm: NFM15/18/21/3D/31

100-200μm: NFM41

[Guideline of solder paste thickness]

2.6

2.5

4.4

1.0

0.6

1.2

NFM21PS

2.0

2.5

3.9

1.0

0.6

0.8

NFM3DCC/3DPC

NFM31PC/31KC

NFM18PS

2.6

3.5

5.5

1.5

0.6

1.0

NFM41CC/41PC

NFM15CC/15PC

2.2

1.0

0.4

0.6

1.2

NFM18CC/18PC

0.4

NFM21CC/21PC

1.4

2.6

0.6

0.8

0.6

1.9

0.8

0.4

0.1

1.2

1.20.05

2.0

0.85

1.85

0.6

1.6

1.2

2.6

1.25

0.4

1.8

0.8

0.25

0.7

1.3

0.25

0.3

0.75

!

Note

• Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

Loading...

Loading...