!Caution

4-1. Reflow Soldering

1. When sudden heat is applied to the components, the

mechanical strength of the components will decrease

because a sudden temperature change causes

deformation inside the components. In order to prevent

mechanical damage to the components, preheating is

required for both the components and the PCB.

Preheating conditions are shown in table 1. It is required to

keep the temperature dierential between the solder and

the components surface (ΔT) as small as possible.

2. When components are immersed in solvent aer mounting,

be sure to maintain the temperature dierence (ΔT)

between the component and the solvent within the range

shown in table 1.

Recommended Conditions

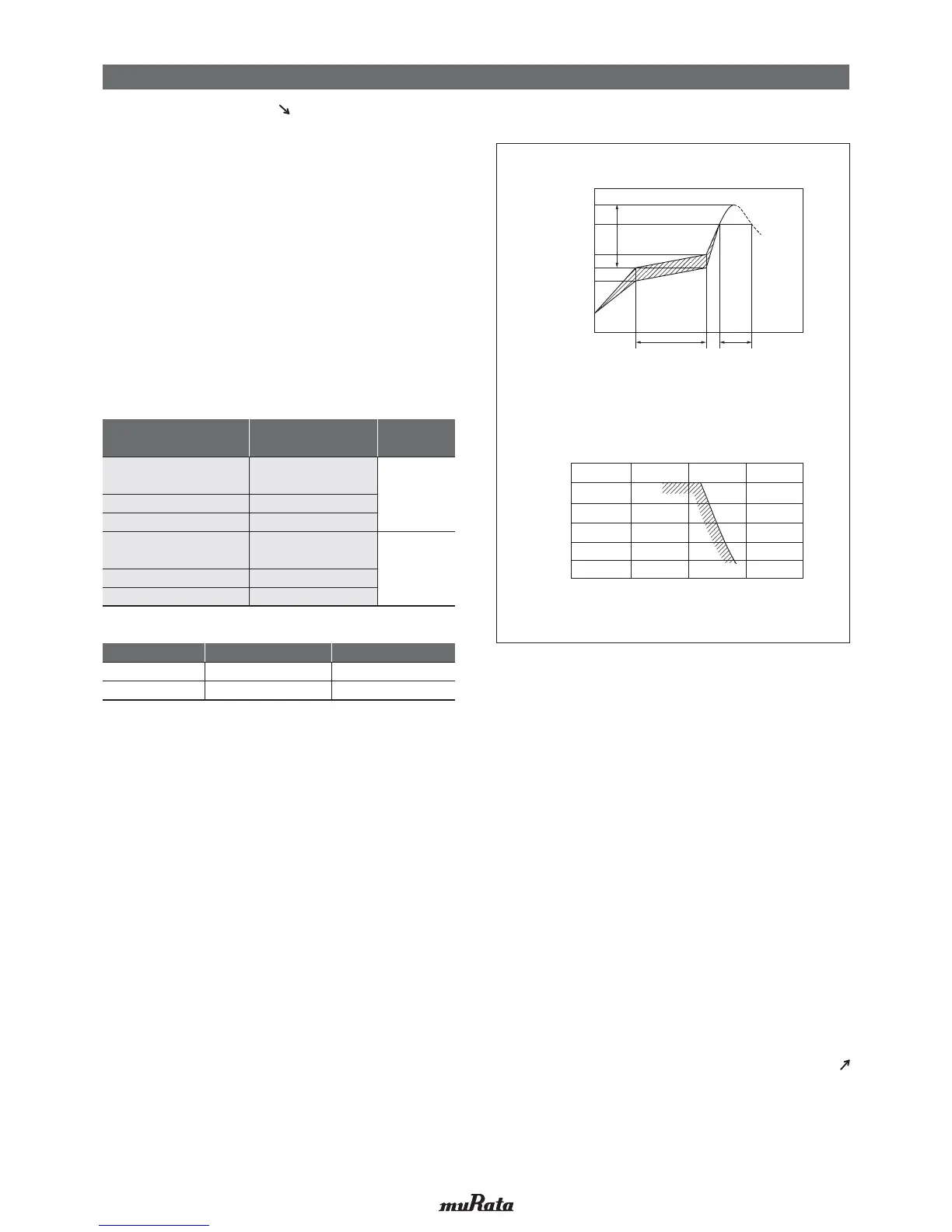

[Example of Temperature Conditions for Reflow Soldering]

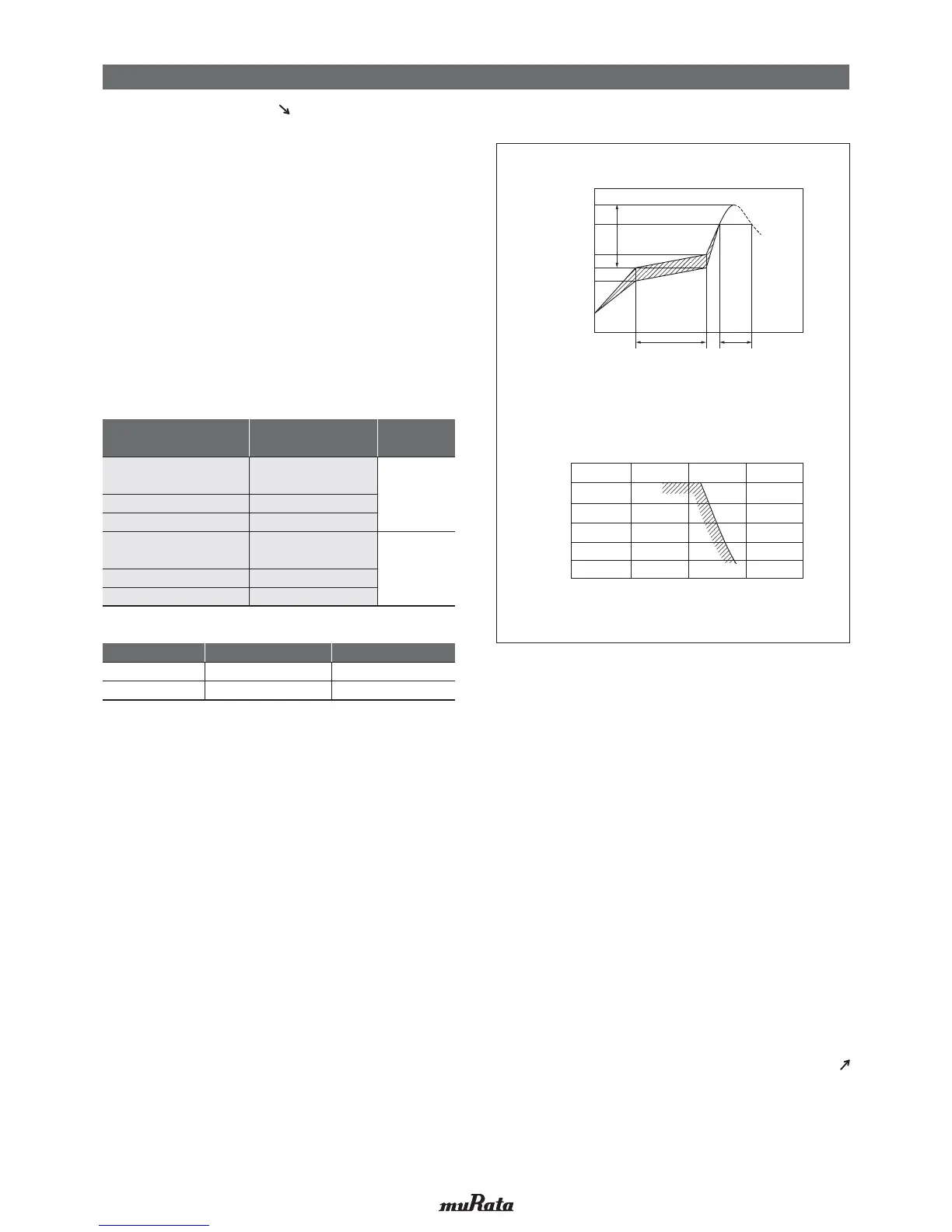

[Allowable Reflow Soldering Temperature and Time]

In the case of repeated soldering, the accumulated

soldering time must be within the range shown above.

Temperature

Incase of Lead Free Solder

( ): In case of Pb-Sn Solder

Soldering Time (s)

260

270

280

250

240

230

220

0 30 60 90 120

Soldering Temperature (°C)

Peak Temperature

Atmosphere

Pb-Sn Solder

230 to 250°C

Air

Lead Free Solder

240 to 260°C

Air or N2

60-120 seconds 30-60 seconds

ΔT

Gradual

Cooling

Soldering

Preheating

220°C (200°C)

190°C (170°C)

170°C (150°C)

150°C (130°C)

Time

Temperature (°C)

Peak Temperature

Pb-Sn Solder: Sn-37Pb

Lead Free Solder: Sn-3.0Ag-0.5Cu

3. When a capacitor is mounted at a temperature lower

than the peak reflow temperature recommended by the

solder manufacturer, the following quality problems can

occur. Consider factors such as the placement of

peripheral components and the reflow temperature

setting to prevent the capacitor’s reflow temperature

from dropping below the peak temperature specified. Be

sure to evaluate the mounting situation beforehand and

verify that none of the following problems occur.

F0-.',1-*"#05#22 '*'27

F-*"#04-'"1

F-11' *#-!!300#,!#-$5&'1)#0',%

F0-.', -,"',%120#,%2&

F0-.',1#*$Q*'%,+#,2.0-.#02'#1

F-11' *#-!!300#,!#-$2-+ 12-,#1,"G-01&'x',%-,

the land patterns of the circuit board

GRM/GJM/GQM/GR3/

GRJ/KRM/LLR/NFM/GR7

02/03/15/18/21/31

LLL

02/03/15/18/1U/21/31

ZRB 15/18

GR3/GRJ/GRM/KR3/KRM

GA2/GA3/GR4

32/42/43/52/55

LLA/LLM 18/21/31

GQM 22

ΔT

<

=

190°C

ΔT

<

=

130°C

Series

Chip Dimension Code

(L/W)

Temperature

Dierential

Table 1

Continued from the preceding page.

Continued on the following page.

!

Note

• Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

Loading...

Loading...