!Caution

Solder Amount

in section

4-3. Correction of Soldered Portion

When sudden heat is applied to the capacitor, distortion

caused by the large temperature dierence occurs

internally, and can be the cause of cracks. Capacitors also

tend to be aected by mechanical and thermal stress

depending on the board preheating temperature or the

soldering fillet shape, and can be the cause of cracks. Please

refer to "1. PCB Design" or "3. Optimum solder amount" for

the solder amount and the fillet shapes.

Do not correct with a soldering iron for ZRB series.

Correction with a soldering iron for ZRB series may cause

loss suppress acoustic noise, because the solder amount

become excessive.

1. Correction with a Soldering Iron

1-1. In order to reduce damage to the capacitor, be sure

to preheat the capacitor and the mounting board.

Preheat to the temperature range shown in Table 3.

A hot plate, hot air type preheater, etc. can be used

for preheating.

1-2. Aer soldering, do not allow the component/PCB to

cool down rapidly.

1-3. Perform the corrections with a soldering iron as

quickly as possible. If the soldering iron is applied too

long, there is a possibility of causing solder leaching

on the terminal electrodes, which will cause

deterioration of the adhesive strength and other

problems.

2. Correction with Spot Heater

Compared to local heating with a soldering iron, hot air

heating by a spot heater heats the overall component and

board, therefore, it tends to lessen the thermal shock. In

the case of a high density mounted board, a spot heater

can also prevent concerns of the soldering iron making

direct contact with the component.

2-1. If the distance from the hot air outlet of the spot

heater to the component is too close, cracks may

occur due to thermal shock. To prevent this problem,

follow the conditions shown in Table 4.

2-2. In order to create an appropriate solder fillet shape, it is

recommended that hot air be applied at the angle shown

in Figure 1.

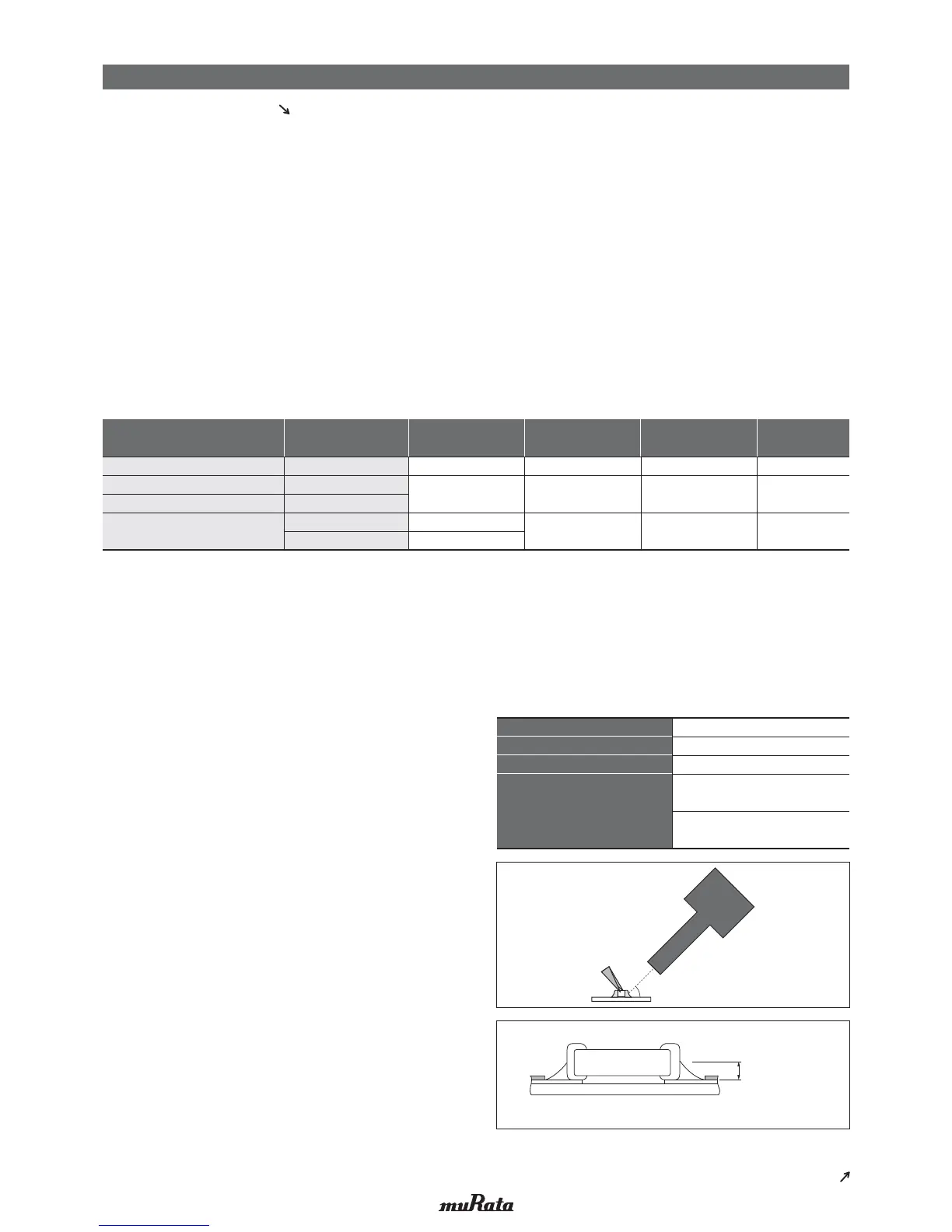

3. Optimum solder amount when re-working with a soldering iron

3-1. If the solder amount is excessive, the risk of cracking is

higher during board bending or any other stressful

condition.

Too little solder amount results in a lack of adhesive

strength on the termination, which may result in chips

breaking loose from the PCB.

Please confirm that solder has been applied smoothly and

rising to the end surface of the chip.

Table 3

GJM/GQM/GR3/GRJ/GRM/GR7

ΔT

<

=

190°C

ΔT

<

=

130°C

350°C max.

280°C max.

150°C min.

150°C min.

Air

Air

*Applicable for both Pb-Sn and Lead Free Solder.

Pb-Sn Solder: Sn-37Pb

Lead Free Solder: Sn-3.0Ag-0.5Cu

*Please manage ΔT in the temperature of soldering iron and the preheating temperature.

GRJ/GRM/GR4/GA2/GA3

GQM

03/15/18/21/31

NFM

ΔT

<

=

190°C

350°C max.

340°C max.

150°C min. Air

3D/41

15

32/42/43/52/55

22

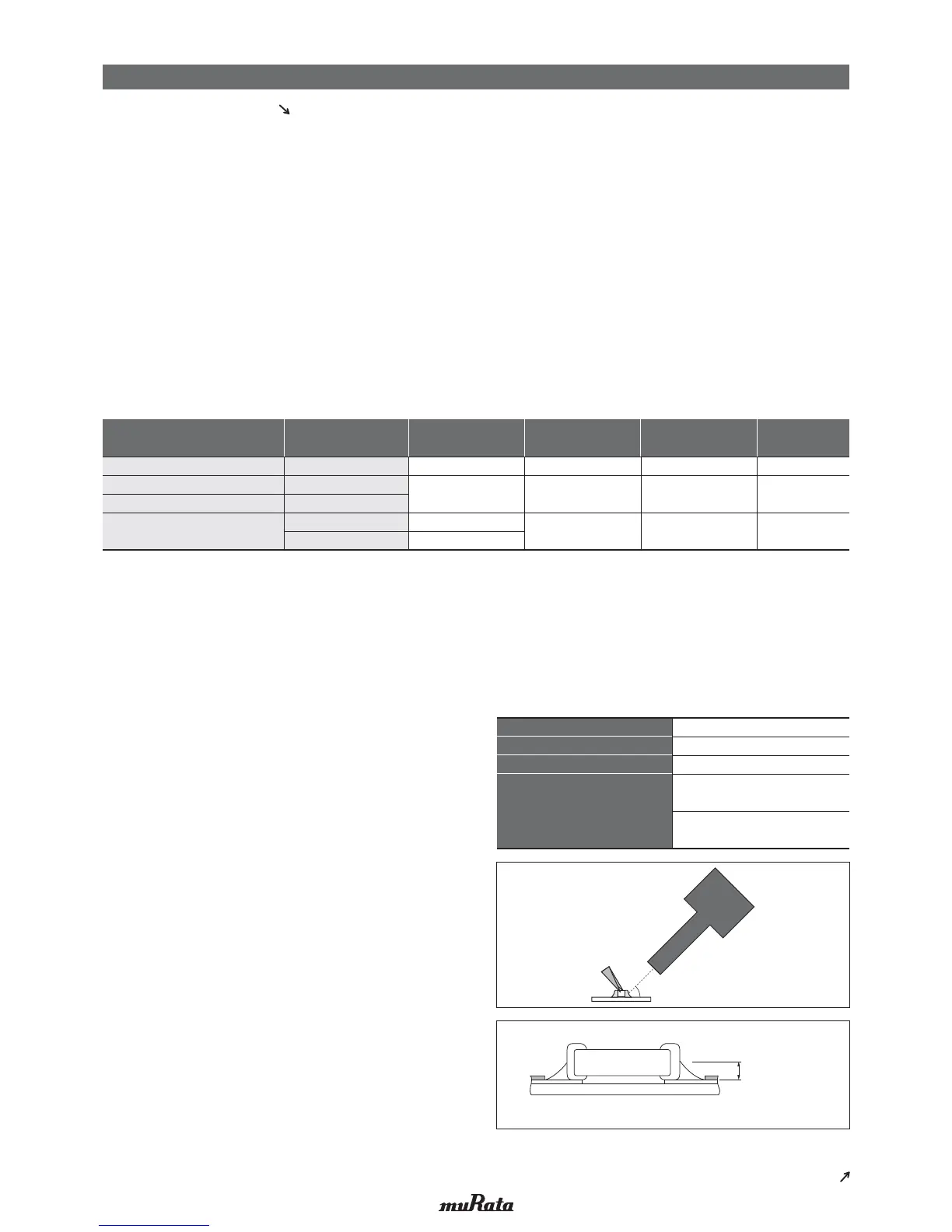

Table 4

Hot Air Application Angle

45° *Figure 1

Distance

5mm or more

Hot Air Temperature Nozzle Outlet

400°C max.

Application Time

Less than 10 seconds

(1206 (3216M) size or smaller)

Less than 30 seconds

(1210 (3225M) size or larger)

an Angle of 45°

One-hole Nozzle

[*Figure 1]

Series

Chip Dimension Code

(L/W)

Temperature

Dierential (ΔT)

Atmosphere

Temperature of

Soldering Iron Tip

Preheating

Temperature

Continued from the preceding page.

Continued on the following page.

!

Note

• Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

Loading...

Loading...