MAINTENANCE

25

F–030767L

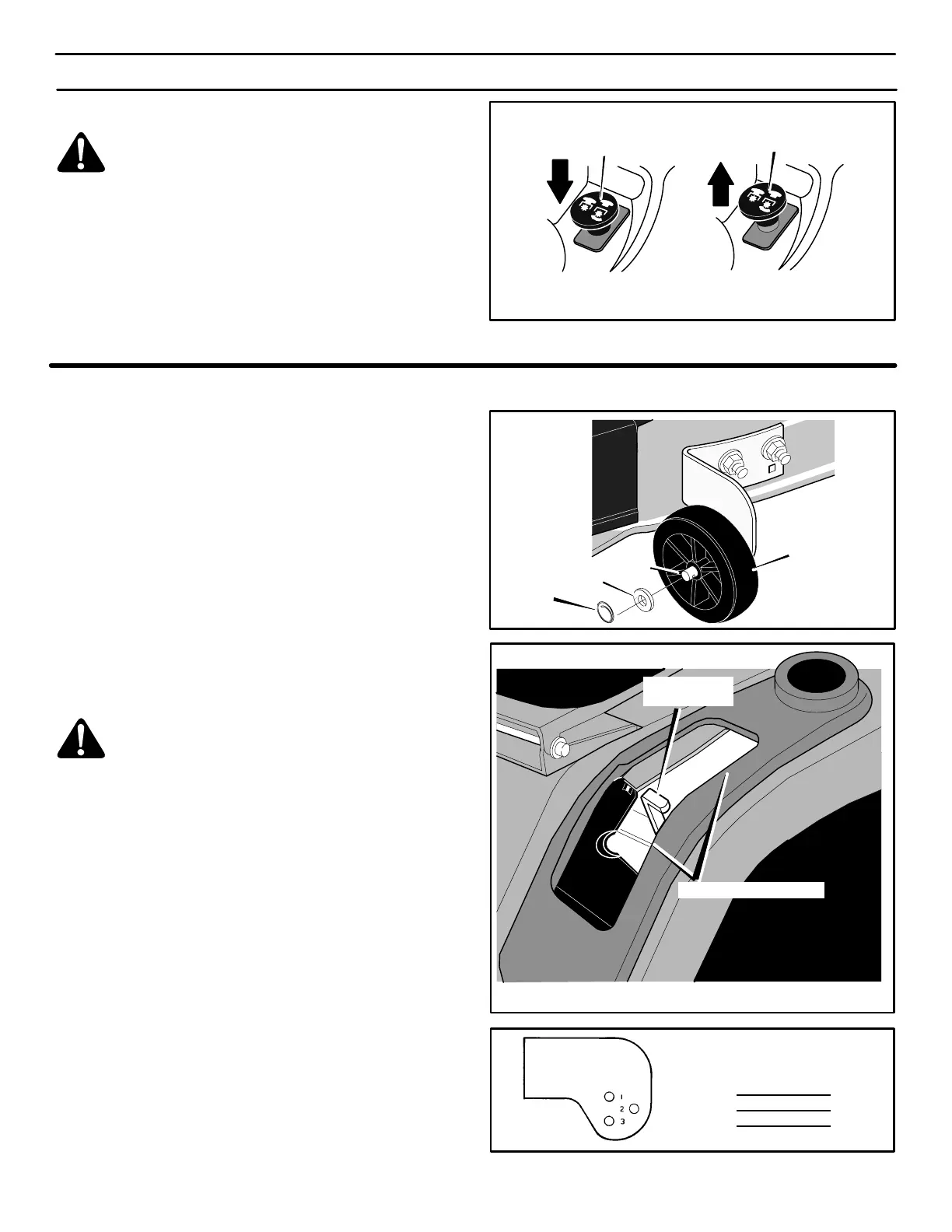

HOW TO CHECK THE BLADE ROTATION CONTROL

WARNING: To prevent an injury, the blade rotation

control must operate correctly.

1. With the engine running, move the blade rotation control to

the ENGAGED positon (Figure 18).

2. Move the blade rotation control to the DISENGAGE position.

All movement will stop within five seconds. If there is movement

of the belt or if the blades continue to rotate, engage and disen-

gage the blade rotation control five times This will remove

any excess rubber from a new mower drive belt. If you need

assistance, take the unit to an authorized service center.

Figure 18

Engage Position

Disengage Position

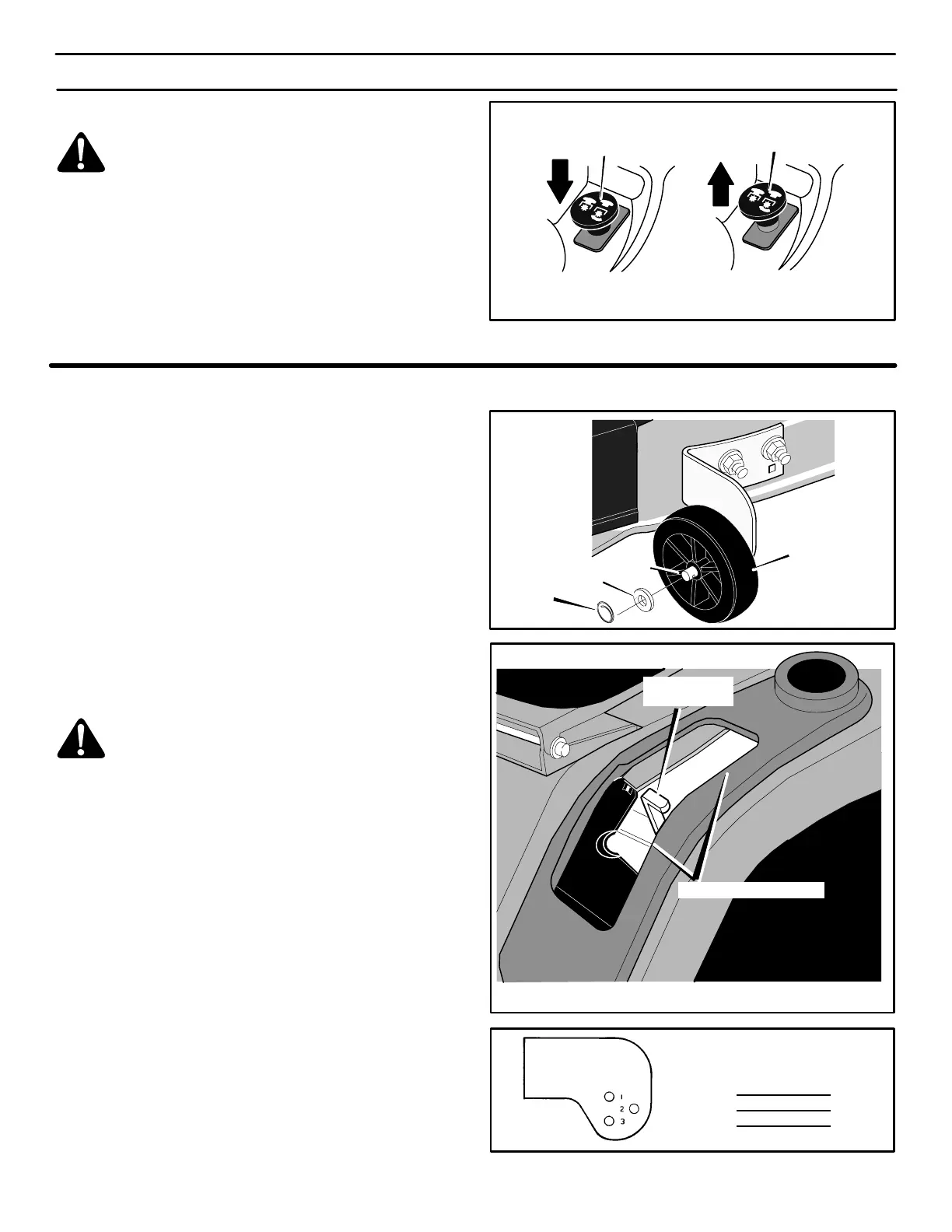

HOW TO ADJUST THE GAUGE WHEELS

The axle bolts for the gauge wheels were mounted in the LOW cut

position. To change the position of the gauge wheels, move the axle

bolts as follows.

IMPORTANT: Before you adjust the gauge wheels, you must do

the following. Make sure the mower housing is level. Make sure

the height of cut is set at the height you want for your lawn.

Mow a short distance on a flat level area and look at the area

that was cut. If the mower housing does not cut level, see the

instructions “How To Level The Mower Housing.”

WARNING: Before you make an inspection, adjust-

ment, or repair to the unit, disconnect the wire to the

spark plug. Remove the spark plug wire to prevent

the engine from starting by accident.

1. Remove the gauge wheels (Figure 19).

2. Mow a short distance on a flat level area to check the level of

cut and the height of cut. Look at the cutting height position

number on the height-of-cut indicator (Figure 20).

3. Look at each gauge wheel bracket. There are 3 holes in each

bracket and a number next to each hole. The number for the

cutting height position on the height-of-cut indicator indicates

the correct hole to use on each gauge wheel bracket

(Figure 21).

4. Assemble the axle bolts to the gauge wheel brackets using

the correct hole in the bracket as indicated (Figure 21).

NOTE: If the height-of-cut position is changed, you must move

the gauge wheels to the correct hole (Figure 21) to keep a level

height of cut.

Gauge Wheel

Figure 19

Locking

Ring

Washer

Axle Bolt

Figure 20

Cutting Height Positions

Height-Of-Cut

Indicator

Wheel Bracket

Hole No.

Cutting Height

Position No.

1 1

2 2

3 3,4,5,6

Figure 21

Gauge

Wheel Bracket

Loading...

Loading...