8

2A3 – MODELS WITH GRAVITY DRAINAGE

N.B.

The drainage line must comprise of a free

flow sump pit of the proper size capable

of disposing twice the water flow as

indicated on the data diagram. It must be

close to the drain pipe of the

machine without bending, stretching or

joining the pipe.

- Drain line must reach sump pit free

flowing without constraints, stretching,

bends, kinks, or being forced.

- Connect the waste outlet pipe to the main

drain pipe, fitting a trap, or place the

outlet pipe over an “S” trap set into the

floor.

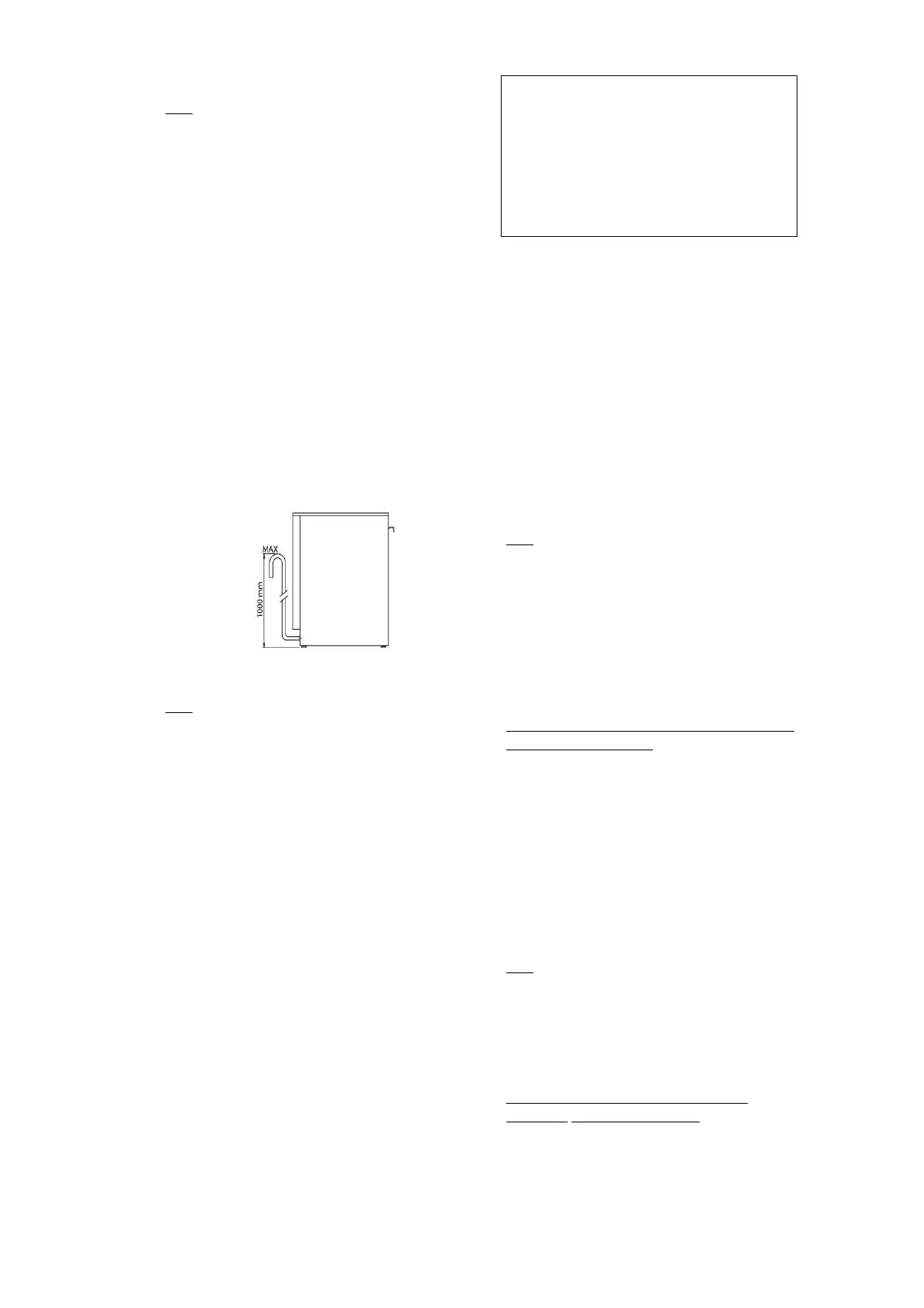

2A4 – MODELS WITH DRAIN PUMP

- Position the outlet pipe at a height

anywhere between 30” and 40” from the

floor. (Fig.6)

Fig. 6

2B - ELECTRICAL CONNECTION

N.B.

All contacts must be mechanically

open, with a ground line included,

min. distance between contacts 3 mm,

with magnetic overload or fuses,

calibrated for a max, sustained current

in agreement with machine data

plate. It must be installed outside the

machine but close to it. It must feed only

one machine at time.

Machine cannot be connected to the

mains using adapters, plug, cables or

cable extensions not properly sized

and must be adequate for the

machine’s power requirements.

- Verify main specifications comply with

indicated requirements on the data plate

located on the front bottom panel of the

machine (par. ID/RATING/DATA PLATE), that

exists for the connection, a main breaker

with proper size suitable for the machine

and a proper ground system.

The line cable should be replaced with a spare

cable supplied by the manufacturer. For

replacement indicate machine type, machine

serial number and possible installation

modifications. The power cable must not be

stretched or kinked during normal operation.

Grounding point on machine must

be connected to the nearest appliance

terminal according to Safety Standards.

2C – WARNING MESSAGES

DISPLAYED ON THE CONTROL

PANEL

N.B.

If the machine is in OFF mode, warning

messages will not be displayed. Turn ON

the machine to be able to visualize the

warning message on the appliance.

Following warning messages on the display

are provided:

ALR1 - WATER FILL

Water fill not completed during the available

maximum time (10min).

Verify that water supply is correctly

connected, open and free of obstructions.

Verify that solenoid valve filter is free

of possible obstructions and deposits. Verify

that water supply pressure is adequate (par.1D

– Technical Data).

Verify that machine’s door is completely

closed and the overflow device is correctly

positioned inside the tank.

N.B.

If water fill timing expires, the solenoid

valve is automatically interrupted. To

restart solenoid valve press any button on

the control panel.

ALR2 - DRAIN ANOMALY

Drainage not completed during the

maximum programmed timing.

The manufacturer is not responsible for

injuries caused by improper grounding.

The electrical connection must be in

compliance with the national regulations

Loading...

Loading...