2203M4JE-MY-iS2-N_2017.04.

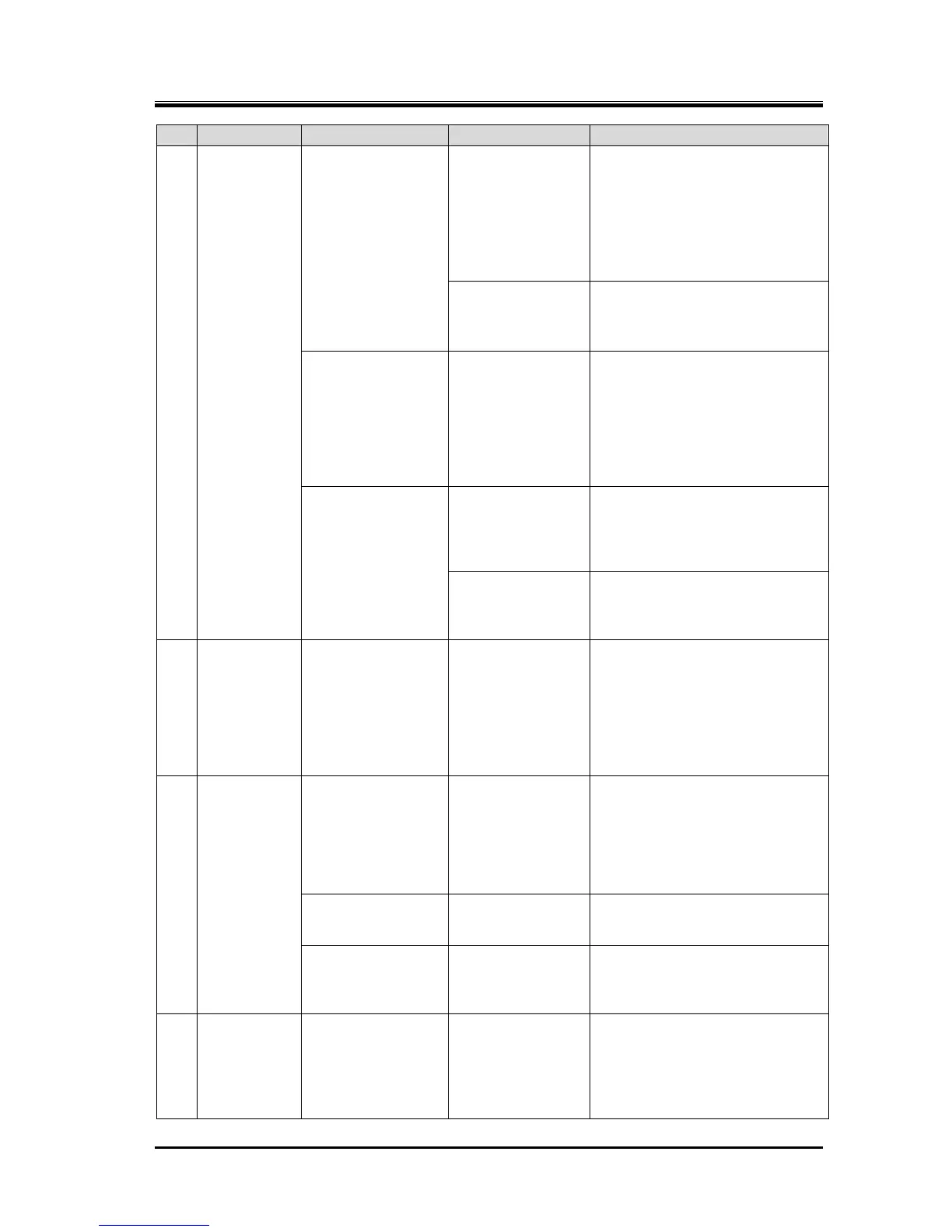

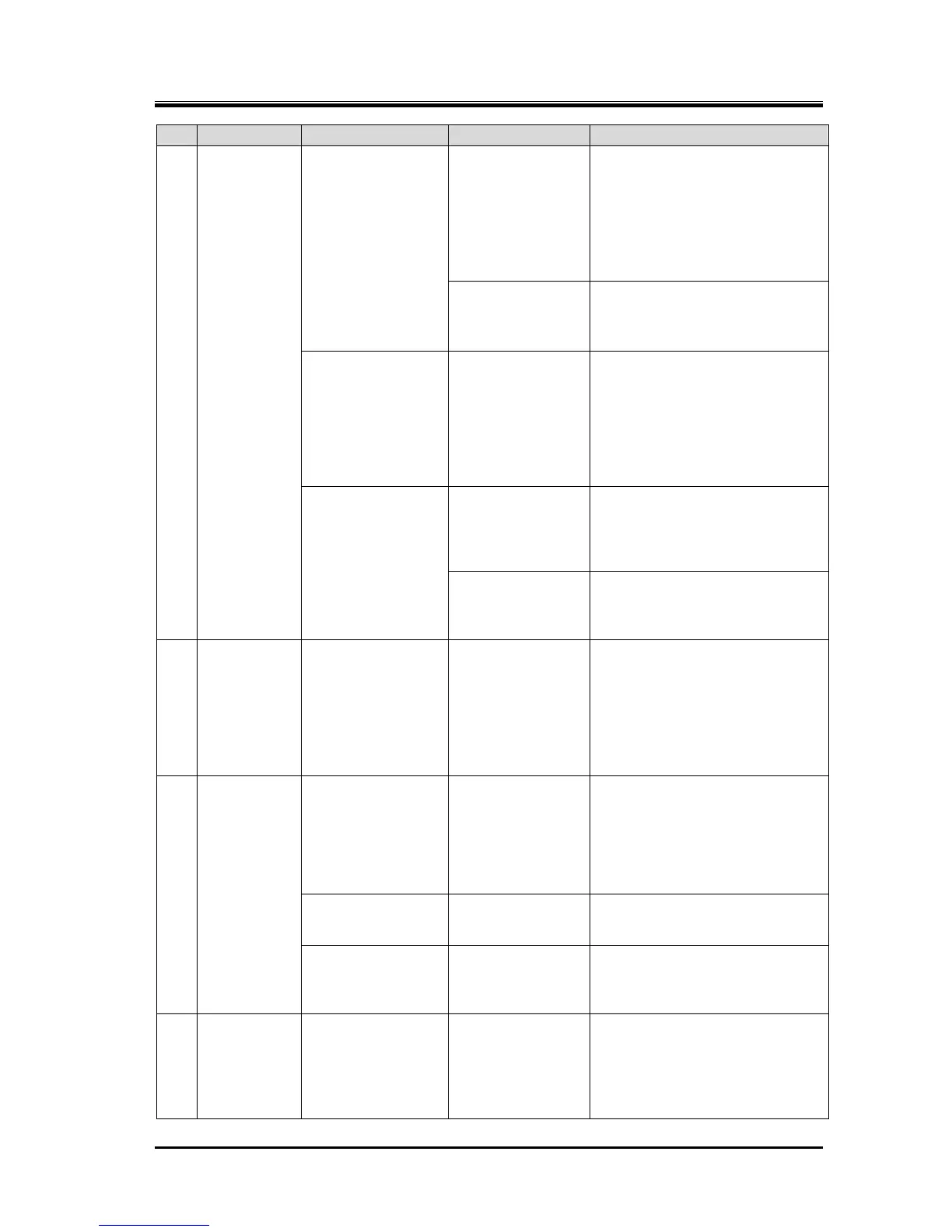

Chapter 6 Troubleshooting

Screw Compressor i-series

6-6

* This occurs

when the

lubricating oil of

refrigerating

machine contains

large amount of

In case of liquid flow-back,

remove the cause(s).

If oil heater or devices on its

control circuit are defective,

replace the defective part.

If deteriorated over time, replace.

For other specific causes, see the

causes/action for symptom

"Overheating of sliding surface".

lubricating oil and

operating conditions

(such as working

temperature range

or refrigerant)

lubricating oil was

selected, or

operating

conditions have

changed after

installation of the

If possible, review the operating

conditions.

If not, see Section 4.1"Lubricating

Oil (Refrigerant Oil)" to select

suitable lubricating oil and replace

the whole quantity.

attached to sliding

surfaces, due to

contaminated

Replace the whole quantity of

lubricating oil.

Install bypass filter to oil supply

line.

Disassemble, replace parts and

reassemble.

Use assembly check sheet to

sound from

mechanical

seal part

after exchange for

new product,

squeaks may be

heard from sliding

surfaces until they

fit together.

surfaces are very

hard and dense,

they need time to

fit together.

Squeaking itself does not cause

leak from seal or deterioration in

sealing function.

Normally, squeaking is heard for

several dozens of hours, however,

it may last longer in rare cases.

→In this case, contact one of our

control solenoid

valve, related

relays, or the like

If deteriorated over time, replace.

If the symptom is caused by water

leakage, etc., remove the

cause(s) and then replace

defective part(s).

For details, refer to the instruction

manual of solenoid valve.

supply line is

defective.

solenoid valve

gland or oil supply

Remove cause, and check oil for

contamination, replace oil if

necessary.

generates

abnormal

vibration

and/or

sound.

thrust bearing

gland(s) are

tightened unevenly.

If lock nuts are not loose and parts

such as thrust bearings are free of

defects, tighten the lock nuts

and/or thrust bearing glands

evenly.

Loading...

Loading...