2203M4JE-MY-iS2-N_2017.04.

Chapter 5 Maintenance and Inspection

Screw Compressor i-series

5.4 Disassembly and Inspection

5-12

5.4 Disassembly and Inspection

Be careful with handling of the parts during disassembly and inspection. Since the compressor rotates

at a very high speed, even the slightest handling error could cause a situation that requires

replacement of the rotor and all other important parts. Such errors can also cause problems or

performance deterioration after the compressor is reassembled. Be sure to fully understand the

following before starting the work.

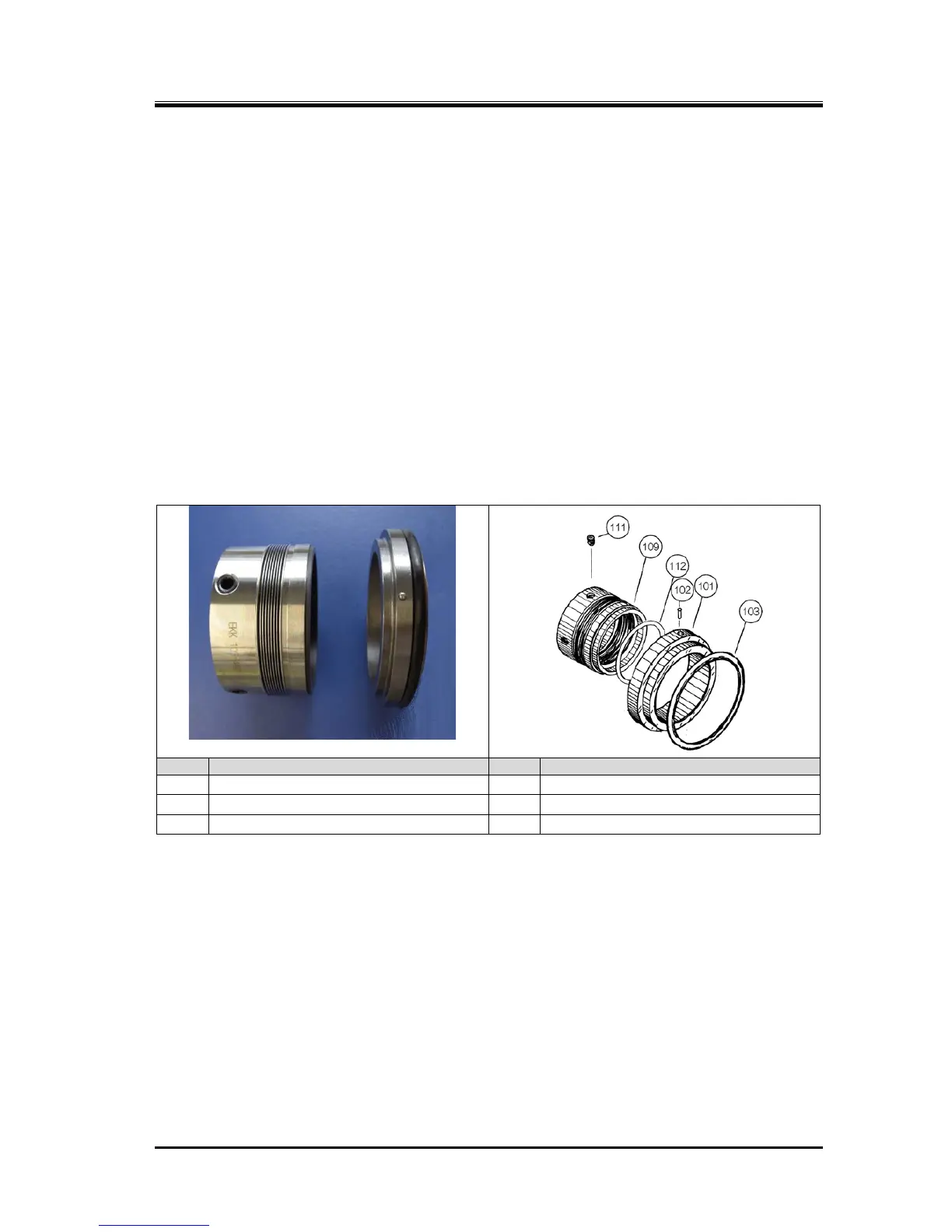

5.4.1 Shaft Seal Block

To prevent refrigerant gas and oil leakage, a reliable mechanical seal assembly is used for the shaft

seal of the M rotor.

Mechanical seal assembly is mainly composed of "rotating ring" installed on the rotor shaft and

"stationary ring" installed in the seal cover. Rotating ring rotates with the shaft, and slides each other

with the stationary ring while maintaining a micron class gap. The sliding each other place is called as

the sliding surface.

Mechanical seals have a precisely machined sliding surface and are made of fragile material.

Handle them with special care since leakage may occur if damaged.

Part Name (Rotating rings)

Part Name (Stationary rings)

5.4.1.1 Disassembly

a) Of the eight hexagon socket head cap screws securing the seal cover [51], remove six and leave

the two on the opposing sides.

b) Loosen the remaining two screws alternately and evenly, a little at a time. After a certain amount of

loosening, the seal cover of the mechanical seal will be pushed by the repulsion force of the bellows

and a gap will appear. A gap will not appear if the gasket is stuck. In that case, remove the seal

cover; push the seal cover by screwing M8 eye bolts into the jacking threaded holes.

c) Use a container to catch the oil that will leak from the gap in the seal.

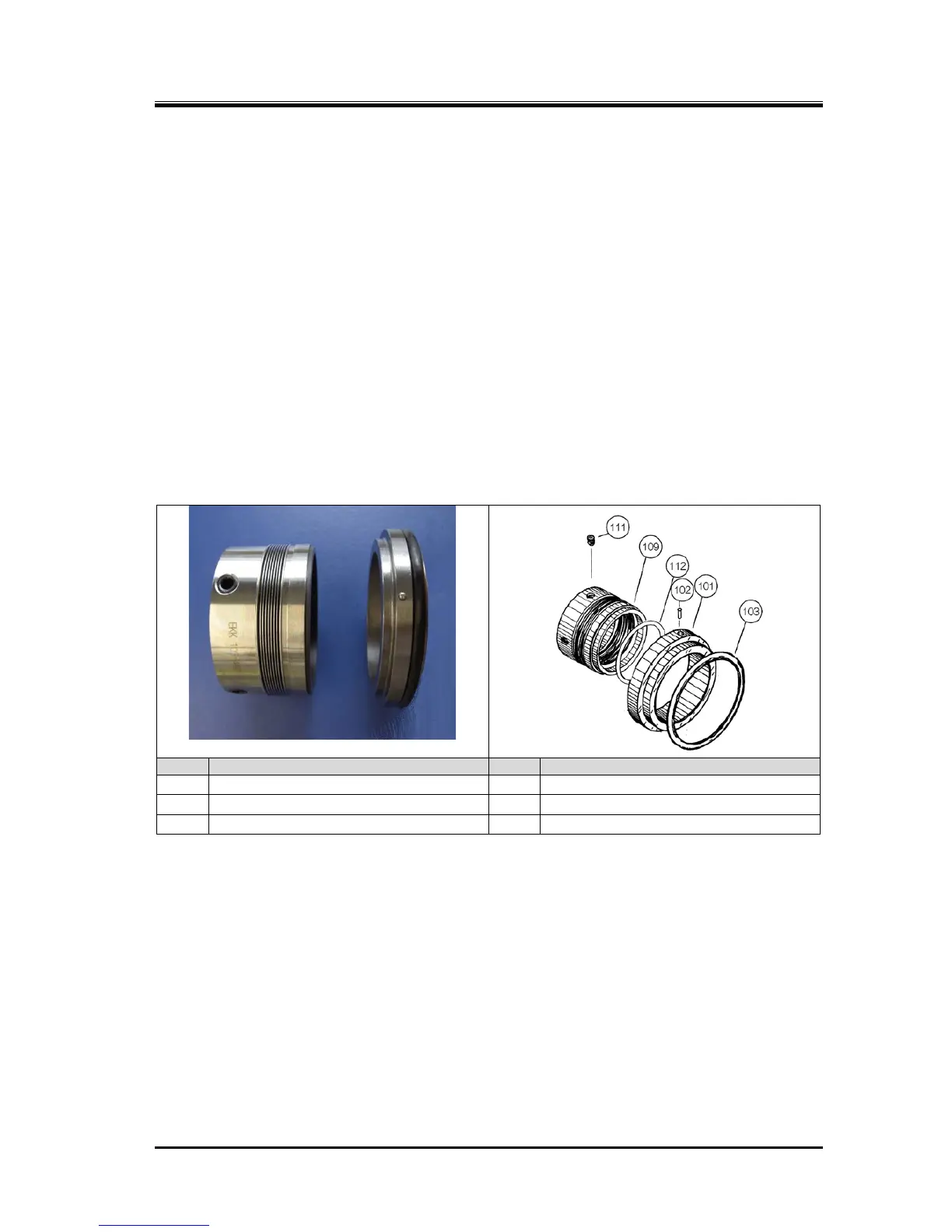

d) Pull out the seal cover, while keeping it parallel with the shaft (rotor shaft). The mating ring is

attached inside the seal cover by using an O-ring [103]. Be careful not to let the mating ring [101]

and the shaft damaged by contact.

e) Remove the O-ring [49] from between the seal cover and seal retainer [48].

Figure 5-1 Details of BBSE Type Mechanical Seal Assembly

Loading...

Loading...