2203M4JE-MY-iS2-N_2017.04.

Chapter 5 Maintenance

Screw Compressor i-series 5.5 Reassembly

5-25

a) The procedure for assembling this block is described in Figure 5-4.

The important points are explained below.

If there is a V-shaped mark for assembly on the outer side of the thrust bearing, assemble with the

pointed end of the mark on the inner side of the machine, as there is a slight directional difference

that affects end clearance adjustment.

If there is no V-shaped mark, assembly direction does not affect end clearance adjustment.

However, to clarify the difference between the inner side and outer side of the machine, assemble

the thrust bearing with the bearing number engravings on the outer side and then put down a

V-shaped mark on the machine's inner side by using blue sharpening stone.

b) After assembling the thrust bearing, install thrust washers [41-1] [41-2], lock washers [40-1][40-2]

and torsional slip washers [237-1] [237-2].

c) Attach dedicated shaft rotation stoppers 1 and 2. Tighten lock nuts [39-1] [39-2] to the specified

torque shown in Table 5-13 or to the specified tightening angle shown in Table 5-14 (refer to Section

7.1 "Tightening Angles for Lock Nuts" in this manual for details), to fix the inner race of the thrust

bearing to the rotor shaft. Be sure to use a new lock washer.

Tightening the lock nut while keeping the setting position between the lock nut wrench hooks

and the lock nut grooves may cause to make the rotor run-

out to enlarge due to uneven

tightening forces.

Change the setting pos

ition between the lock nut wrench hooks and lock nut grooves about four

times when fastening the lock nut.

d) Turn the M rotor shaft by hand, to make sure that rotation of rotors is smooth.

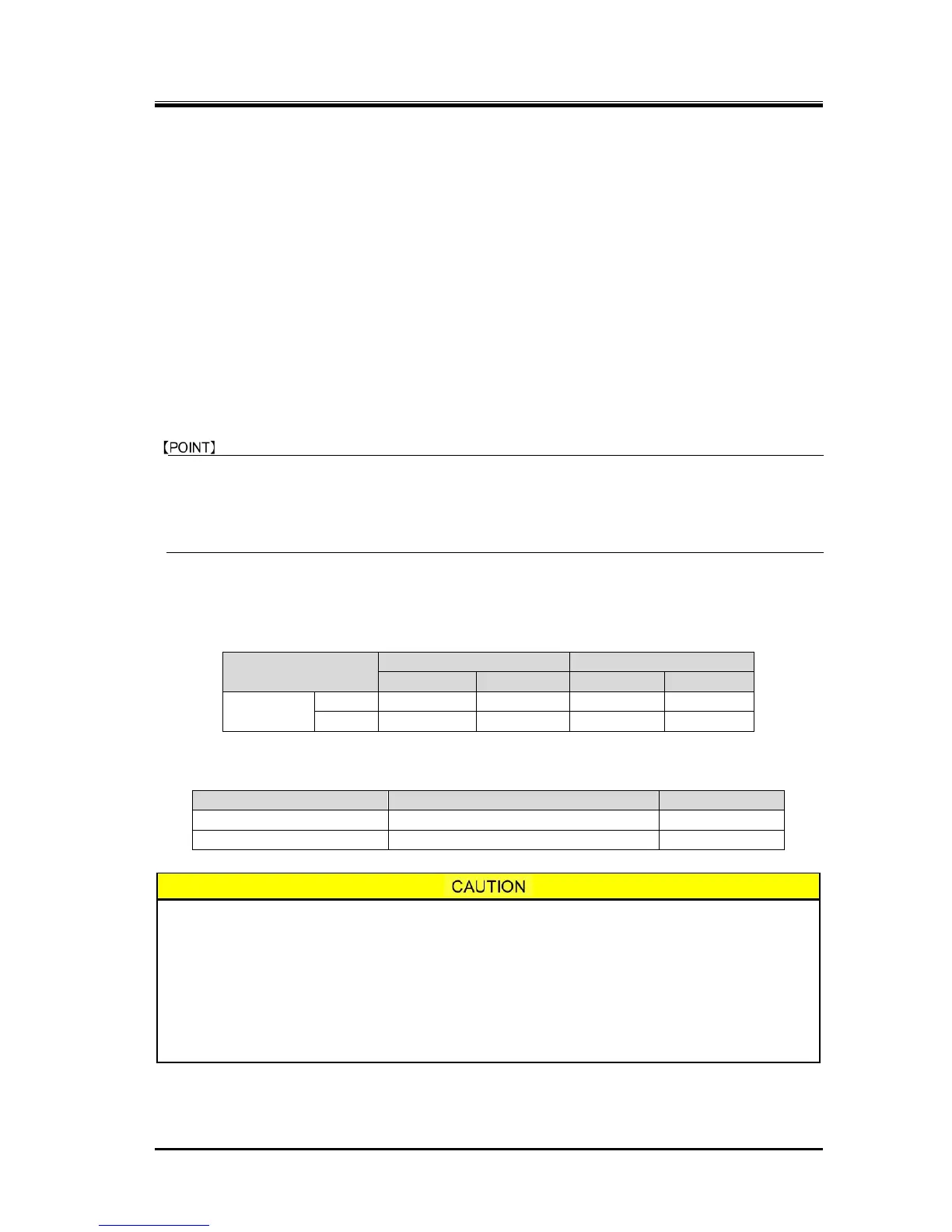

Table 5-13 Tightening Torques for Lock Nuts

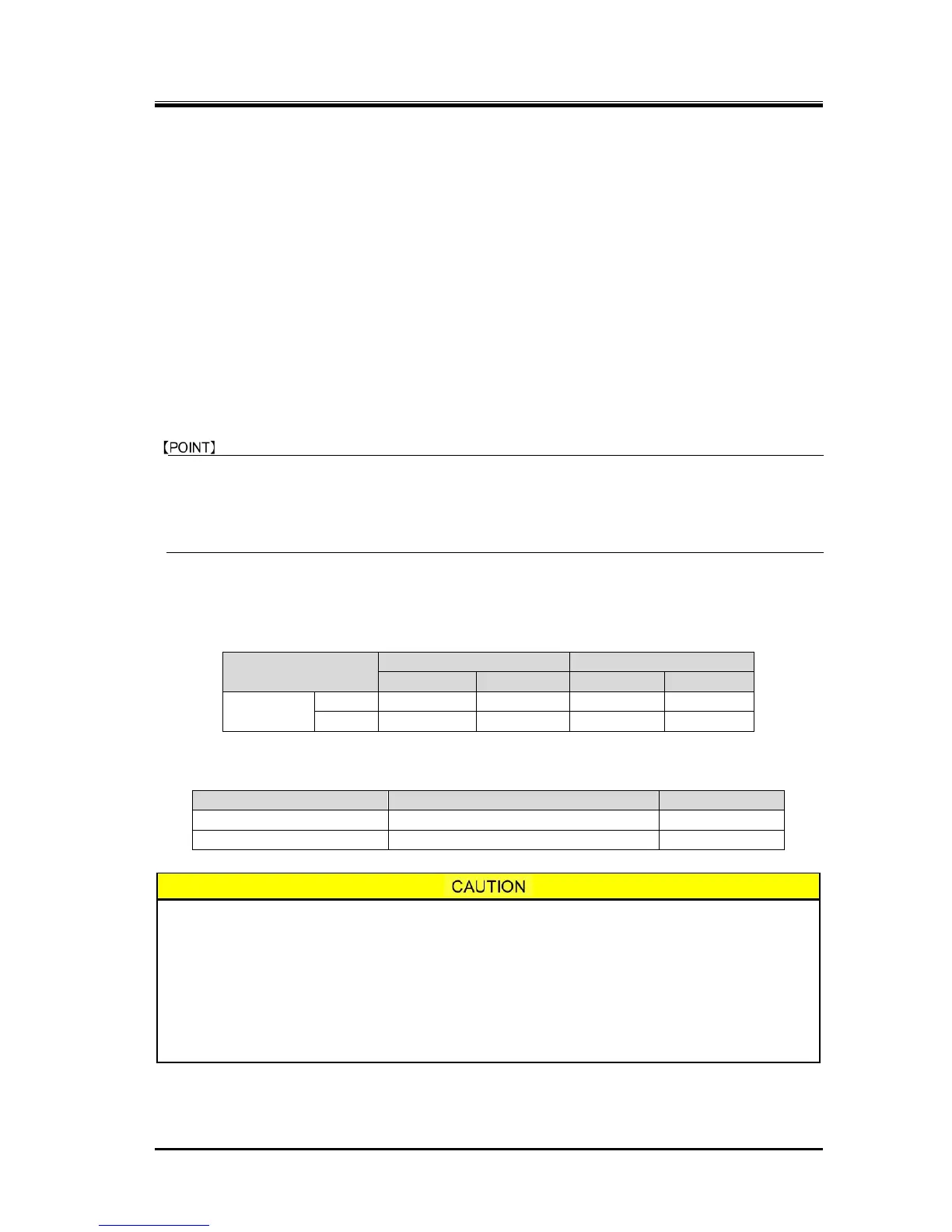

Table 5-14 Tightening Angles for Lock Nuts

For both M and F rotors (i125* / i160*)

Second turn of tightening

For both M and F rotors (i125* / i160*)

Since the inner race of the thrust bearing is loose fit and is secured by the tightening

force of the nut alone, the tightening work is very important.

If the thrust bearing has been replaced, the difference between the bearing inner race

and outer race surfaces will be different even when the parts are manufactured within

standard values. Therefore, fully tightening the nut from the initial use may lead to a

noticeable reduction in the life of bearing, due to a lack of end clearance between the

rotor and the bearing head discharge end face, and also due to indentations on the

contact surface formed by ball pressure. To avoid this, check for end clearance while

tightening.

Loading...

Loading...