(example i125*)

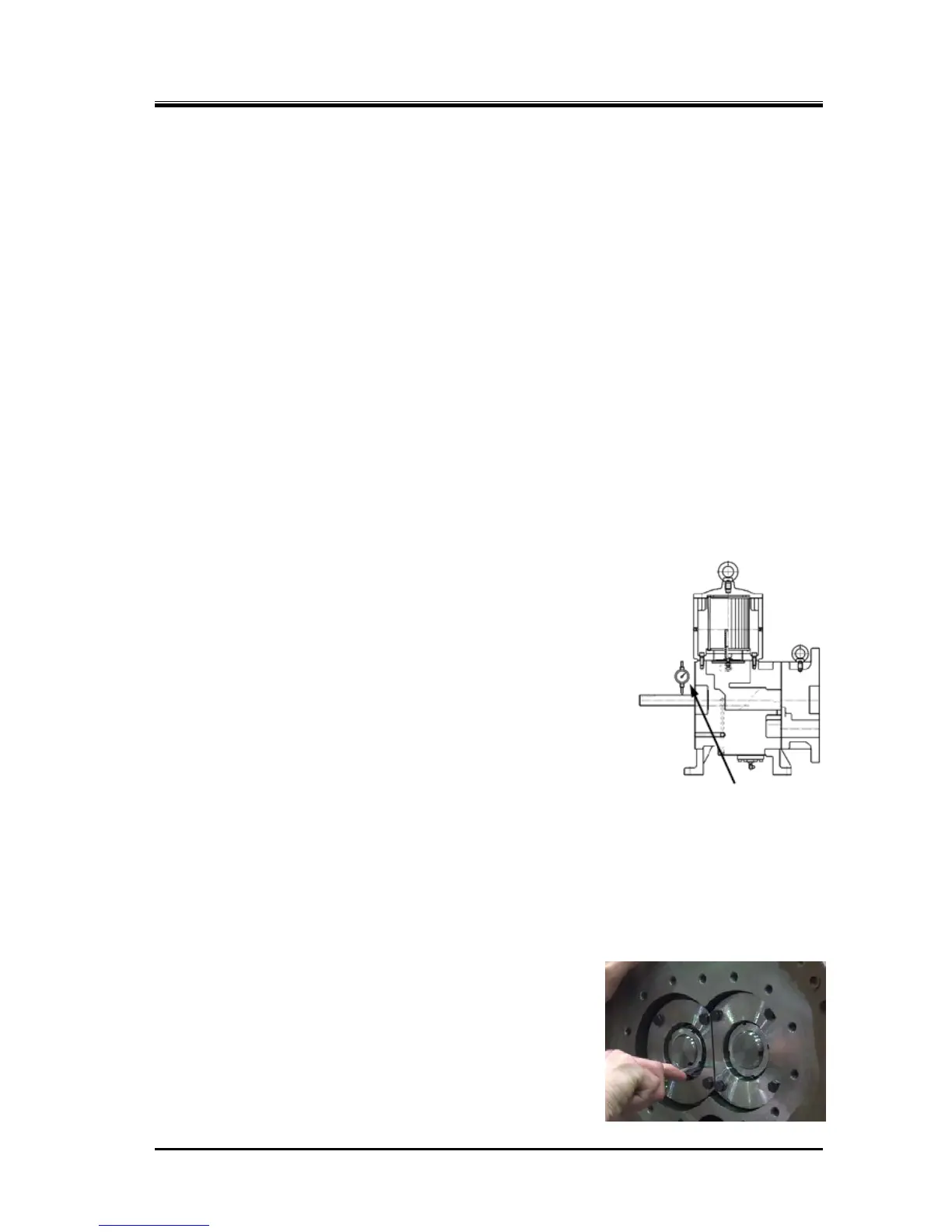

Figure 5-5 Runout

Measurement

5.5.6.2 End Clearance Adjustment

(1) When end clearance is smaller than the specified value

To deal with this, insert shim material (thrust adjustment liner) of required thickness (difference in

thickness from the specified value) between the thrust bearing alignment spacer [42] and thrust

bearing inner race.

* The thrust adjustment liner is not shown in the exploded view, but available from us. Place an

order together with a model name.

Or using a highly accurate surface grinding machine or asking professional service vendors to

grind, grind the surface of thrust bearing outer race spacer [41] by the difference from the

specified value. After grinding the flat surface, measure the whole circumference of the thrust

bearing outer race spacer by using a micrometer, and check that the thickness is even.

(2) When end clearance is larger than the specified value

As the end clearance is excessive, remove shim material (thrust adjustment liner) of a thickness

equal to the difference between the measured value and the specified value if the shim material is

used between thrust bearing alignment spacer and thrust bearing inner race.

Or if the shim material is not used between thrust bearing alignment spacer and thrust bearing

inner race, or even if used but insufficient thickness, grind the surface of thrust bearing alignment

spacer[42] by the difference between the measured value and the specified value or ask

professional vendors to do so.

After grinding the flat surface, measure the whole circumference of the spacer by using a

micrometer, and check that the thickness is even.

(3) Rotor runout measurement

When the end clearance has been adjusted to within the specified

range, place a dial gauge on the seal attachment portion of the M

rotor shaft (FIgure 5-5) . Measure run out by turning the rotor shaft.

The tolerance for runout is 0.03 mm or less for all models.

Runout occurs when the thrust bearing alignment spacer and outer

race spacer are not parallel or when the thrust bearing mark is not at

the correct side. And it occurs if fastening the lock nut performed

without changing the position of the lock nut wrench (i.e., the uneven

fastening of the lock nut).

Moreover small particles of dirt trapped between parts may cause

excessive runout.

If the rotor runout is over the tolerance, even if the end clearance is

within the specified range, disassemble and adjust the relative

positions of the thrust bearing outer race spacer, alignment spacer

and thrust bearing.

This is important because it affects the life of the mechanical seal and

its performance. If axial runout still exceeds the tolerance even when

no such assembly problems exist, contact us. The rotor shaft may be bent.

5.5.6.3 Tightening after End Clearance Adjustment

a) Bend the lock washer claw to the notch of the lock nut which is

tightening the thrust bearing inner race,to prevent rotation.

b) Remove the hexagon head bolts that are tightening thrust

bearing gland [43] one bye one.

Insert spring washer [46] as rotation stopper, and tighten to the

specified torque again.

In case of i160*, use a flat washer [46-2] and spring washer

[46-1], and tighten to the specified torque.

Loading...

Loading...