15

D3

heatless desiccant air dryer

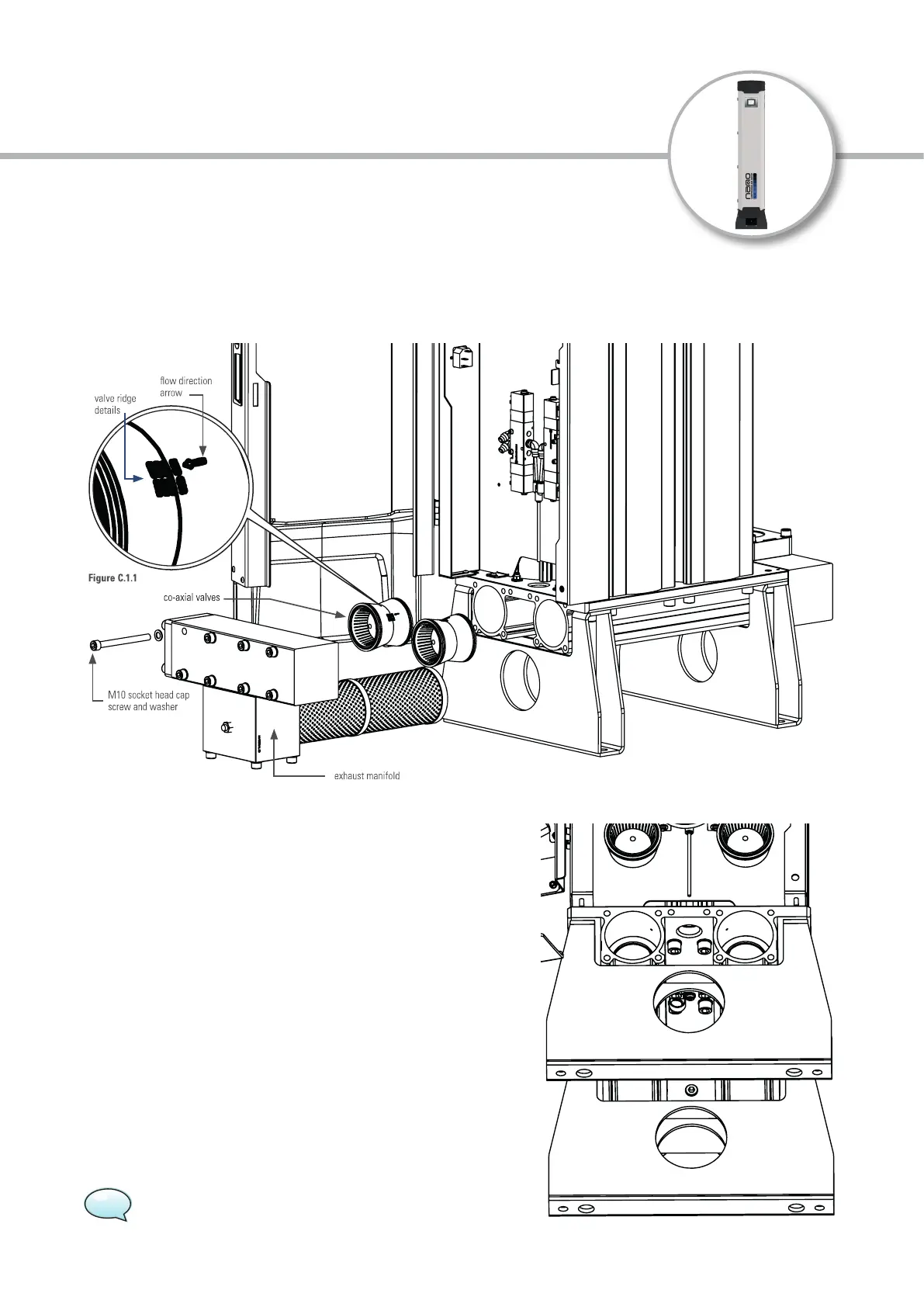

4.1 service ‘C’ instructions - exhaust valves

replacing exhaust valves - (every 4 years or 24,000 hours)

If the exhaust valves are not intented to be serviced, continue to

page 13.

1. Ensure the dryer is shut down and fully depressurised (See page 8,

section 4.1).

2. remove the bottom cover attached by 3 screws.

3. remove the 8 x M10 socket head cap screws and 8 x washers to

release the valve block from the bottom manifold (gure C.1).

4. remove the co-axial valves from the valve orice within the bottom

manifold and discard.

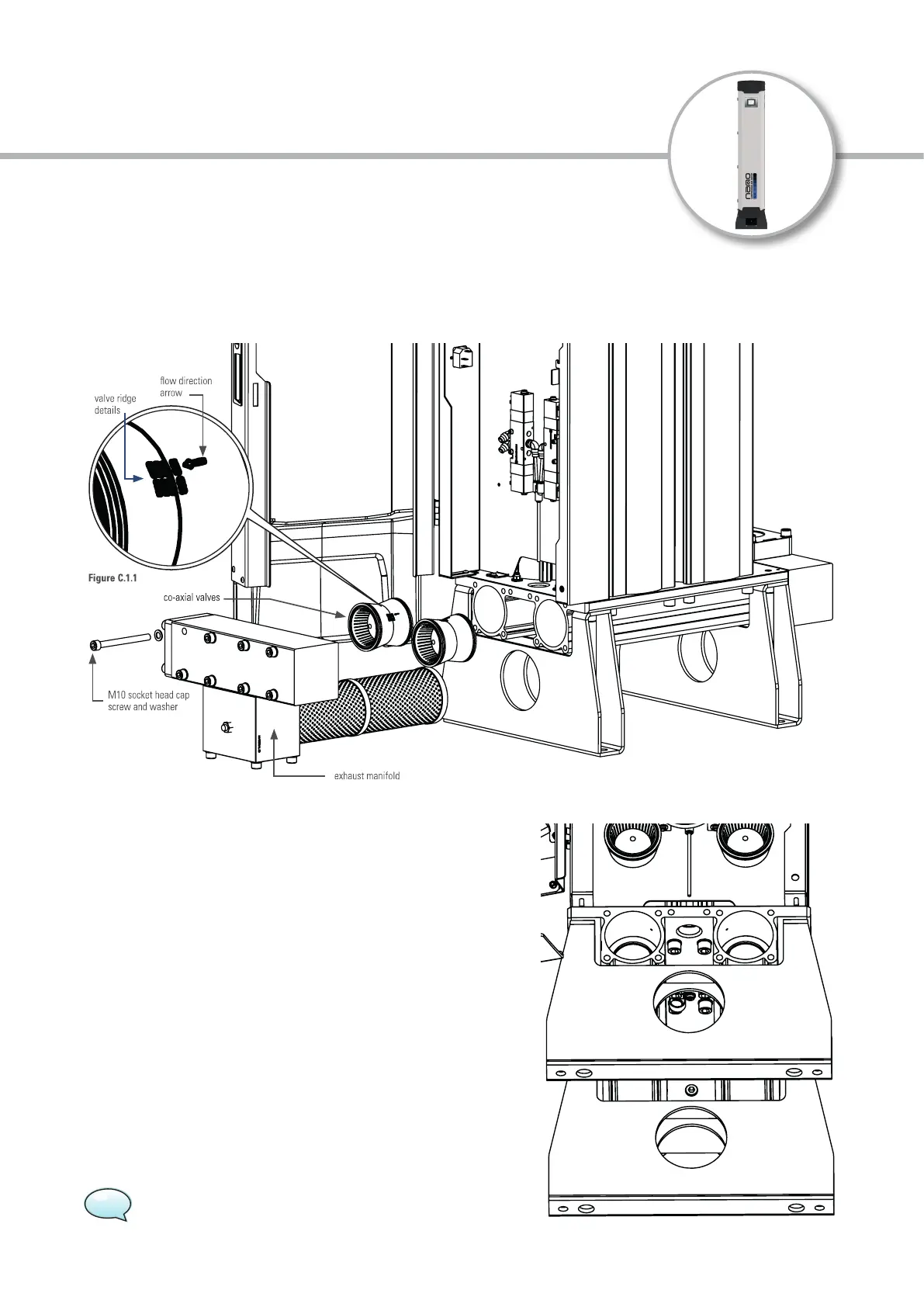

5. lightly grease and insert the new inlet valves into the valve block

ensuring the ow direction arrow is pointing as shown and the

valve ridge details cover the spill port. (See gures C.1.1, and

C.1.2).

6. Reassemble valve block to the bottom manifold (torque setting;

40Nm). Refer to page 19-20 and follow the correct tightening

sequence when replacing block.

7. Ret the bottom cover.

8. Start up the Dryer (page 8), or continue to complete service C

The spoill ports are 1.5mmØ holes

within the bottom manifold.

Loading...

Loading...