LEVELIT{G

The

precision

and durability of the lathe

depends on

its being

perfectly

level.

Final

inspection

rnust

h,e done

only when the machine has beefi

eorrectly

leveled. When the

machine

ison itsfoundation,

level readings

must be done with the level in

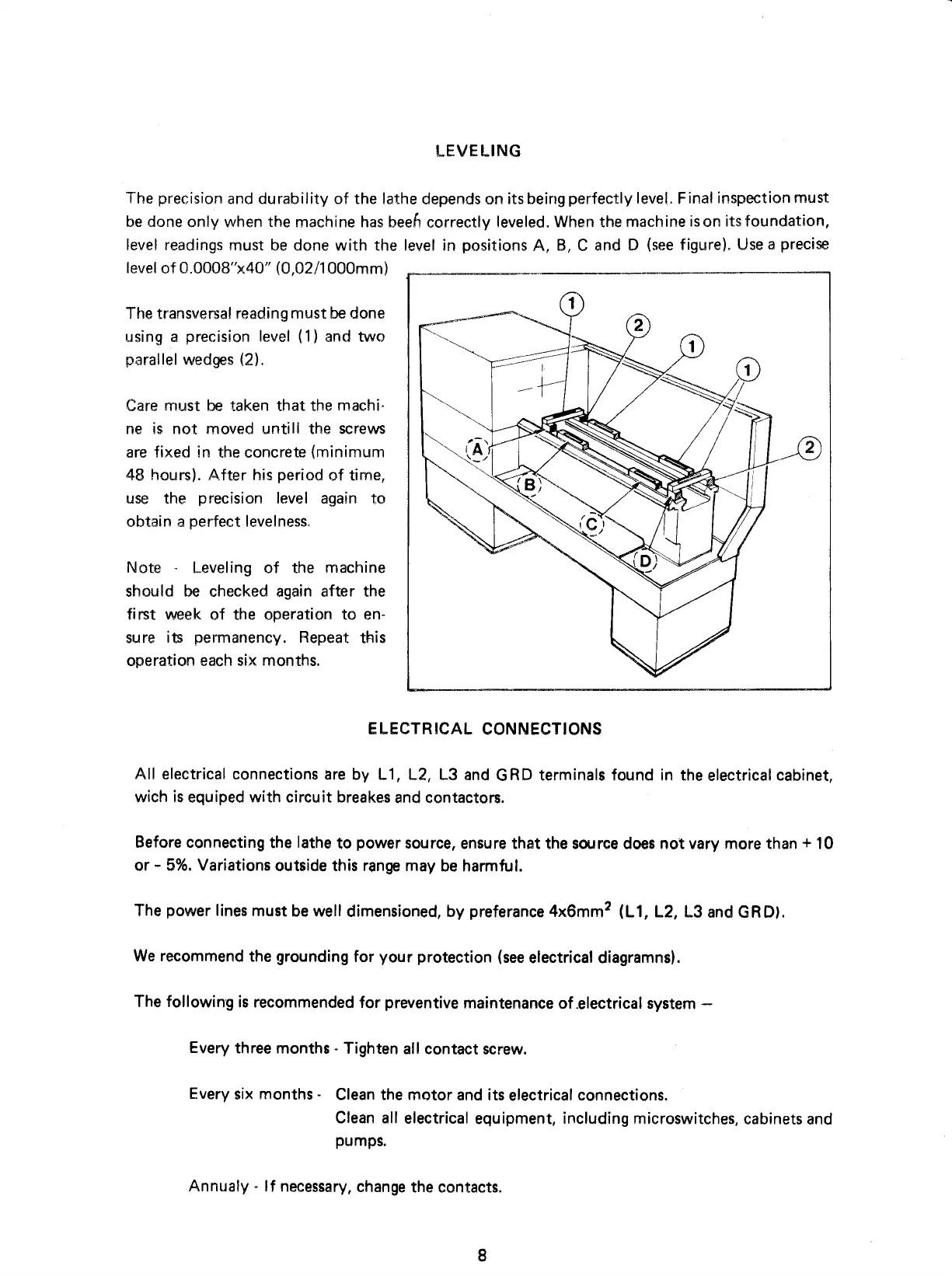

positions

A,

B"

C

and D

(see

figure).

Usea

precise

level

of 0.0008"x40"

Q,A2

n000mm)

The transversal reading

mulst be done

using

a

precision

level

(1)

and two

parallel

wedges

(2).

eare

must

be taken that the

machi-

ne is not moved untill the screws

are

fixed in

the concrete

(minimum

48 hours).

After

his

period

of time,

use the

precision

level again

to

obtain a

perfect

levelness"

Note

Leveling of the

machine

should be checked again after the

first week of the operation to en-

su re

its

permaRency"

Repeat

this

operation

each six months.

ELECTRICAL

CONNECTIONS

All electrical connections

are by L1

,

L2,

L3

and

GRD

terminale found in the

electricalcabinet,

wich is

equiped with circuit breakes

and contactors.

Before connecting

the

lathe

to

power

source,

ensure that the source does not

vary

more than

+

10

or

- 5%. Variatione

outside this range may

be harmful.

The

power

lines must

be well

dimensioned,

by

preferance

4x6mm2

(Ll,

L2, L3

and GR D).

We recommend

the

grounding

for

your protection

(see

electrical diagramns).

The following

is reconnmended

for

preventive

maintenance

of .electrical

system

-

Every

three

months

-

Tighten

all contact

screw.

Every

six

months

-

Clean the motor

and its

electrical

connections.

Clean all

electrical

equipment,

including

microswitches,

cabinets and

pumps,

Annualy

-

lf necessary,

change

the contacts,

Loading...

Loading...