972G00604102 45

REMARKS:

1) This table is for reference purposes only. The vessel manufacturer maintenance table

prevails on this.

2) For applications where the engines are strictly required, the maintenance should occur

in half of the periods indicated above.

3) If the engine remains out of use for a long period, its necessary to turn it on every 2

weeks, and wait until it reach the work temperature.

4) The engine lubricant oil must follow the range of replacement indicated above or the

maximum utilization period of 6 months, what occur first.

5) The coolant liquid must follow the range of replacement indicated above or the maximum

utilization period of 12 months, what occur first.

* Only when applicable.

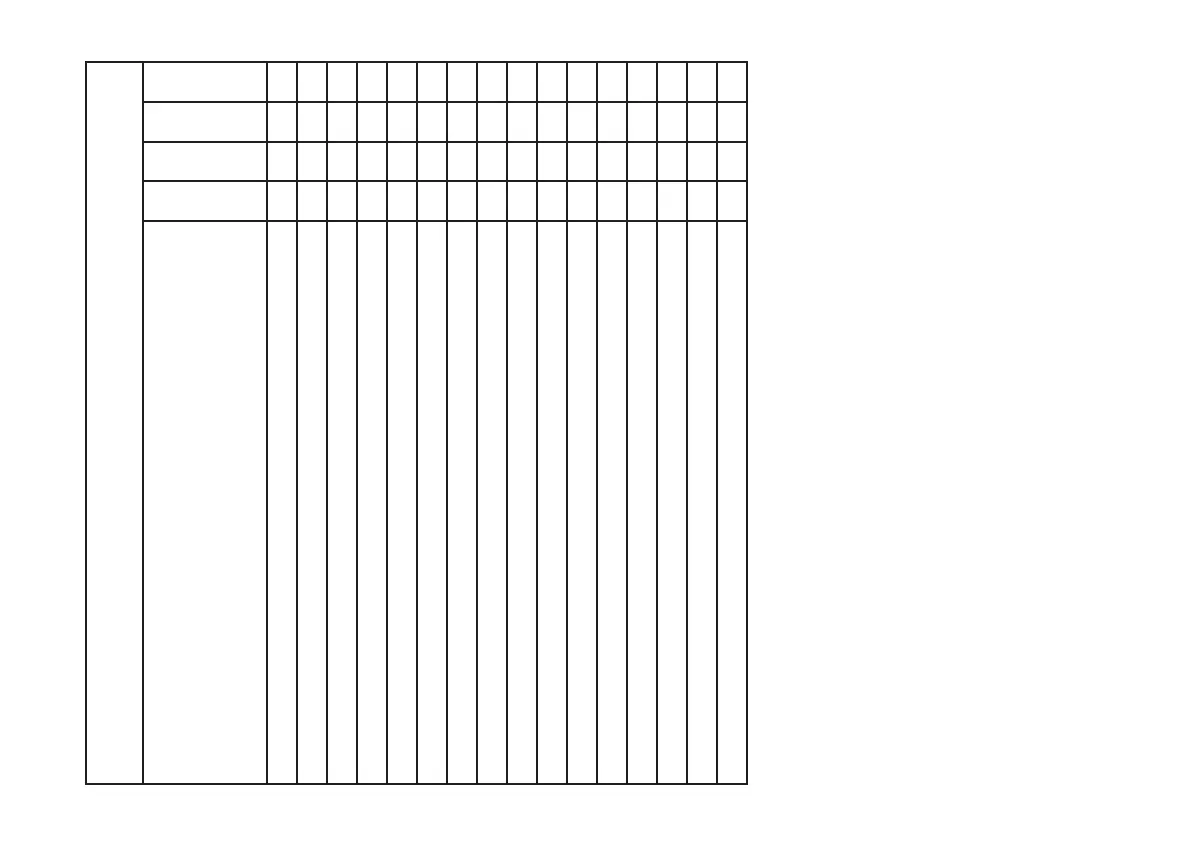

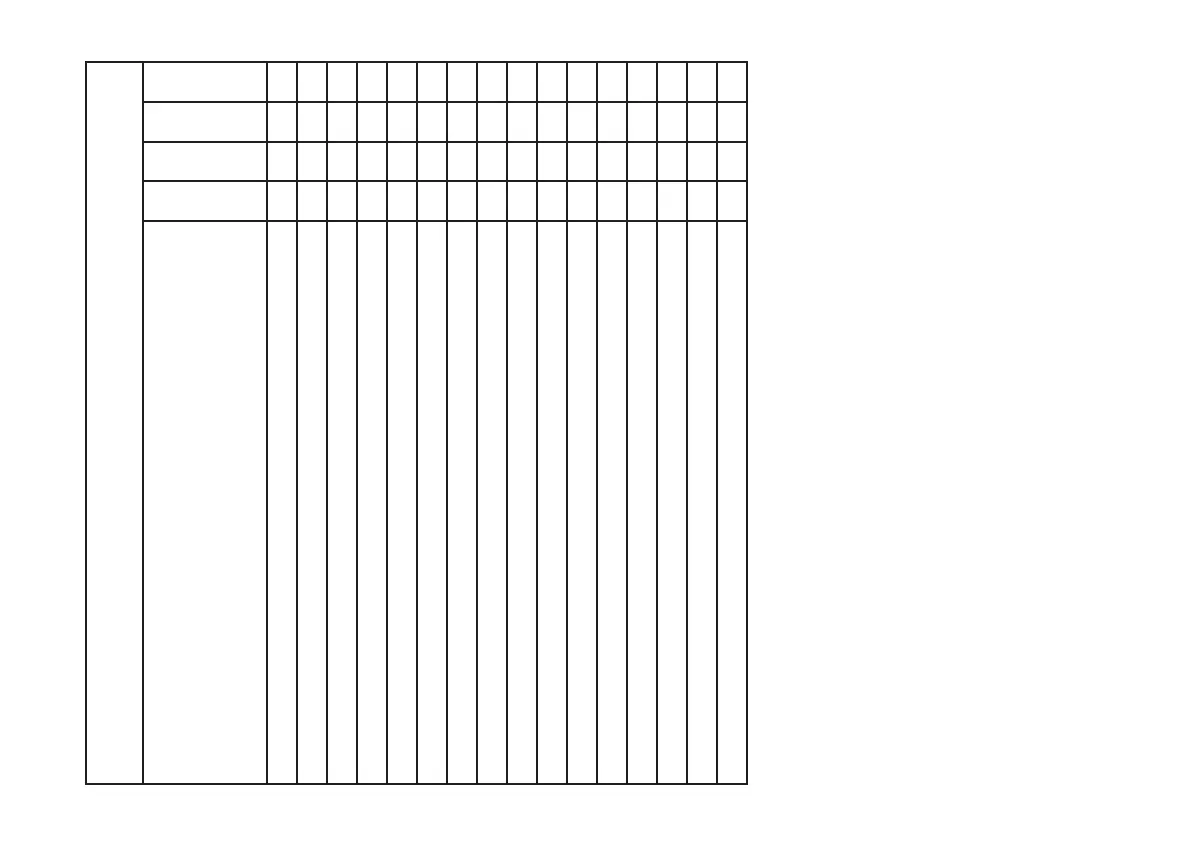

12 SERIES ENGINE - ACTEON (2 VALV.) MECHANICAL INJECTION -

MARINE APPLICATIONS

MAINTENANCE PLAN

Daily

250 h

500 h

1.000 h

DRAIN FUEL FILTER √

CHECK LUBRICANT OIL LEVEL √

CHECK COOLING LIQUID LEVEL √

CHECK ENGINE LEAKS √

CHECK TUBES AND CONNECTIONS √

CHANGE LUBRICANT OIL √

CHANGE LUBRICANT OIL FILTER √

CHANGE FUEL FILTER(S) √

CHECK THE ZINC PROTECTIONS √

CHECK THE CONDITIONS OF THE FILTER √

ADJUST VALVE CLEARANCE √

WASH THE AIR FILTER √

TEST THE NOZZLES √

CHANGE BELT √

CHANGE COOLING SYSTEM LIQUID √

TEST INJECTION PUMP √

Loading...

Loading...