6 of 7

ISSUED: 03-26-10 SHEET #: 125-9106-3 08-04-10

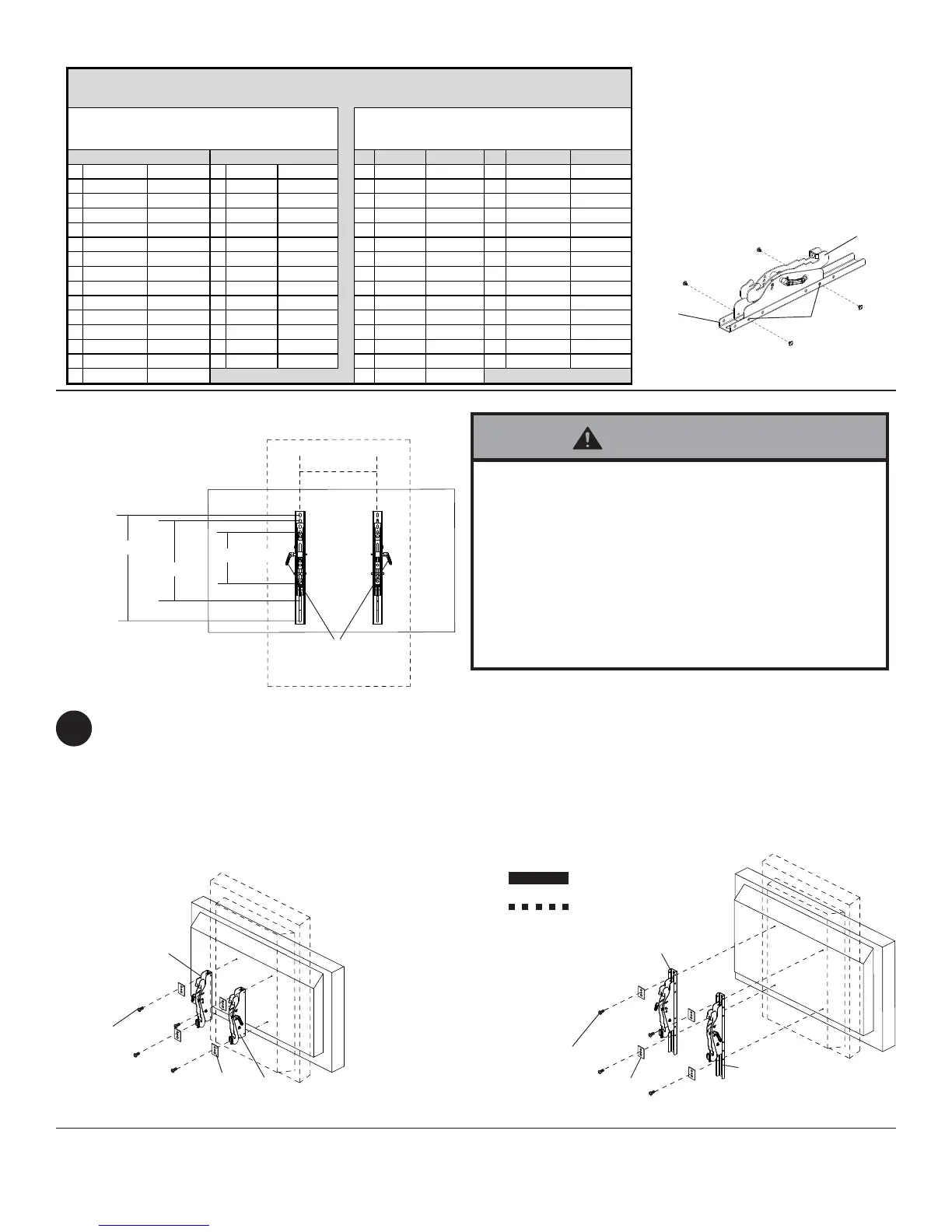

LANDSCAPE PORTRAIT

RecommendedHolePattern RecommendedHolePattern

A 200mmX200mm C 400mmX400mm A 200mmX200mm C 400mmX400mm

B 300mmX300mm D 400mmx200mm B 300mmX300mm D 200mmx400mm

Screen Screw

Size Screen ScrewSize Screen ScrewSize Screen ScrewSize

A ASPV32 M6x12 B P401 M6x12 A ASPV32 M6x12 B P401 M6x12

A ASPV40 M6x12 B P461 M6x12 A ASPV40 M6x12 B P461 M6x12

A E321 M6x12 C P521 M6x12 A E321 M6x12 C P521 M6x12

D E421 M6x12 C P551 M6x12 D E421 M6

x12 C P551 M6x12

D E461 M6x20 B S401 M6x12 D E461 M6x12 B S401 M6x12

A LCD3210 M6x12 B S461 M6x12 A LCD3210 M6x12 B S461 M6x12

A LCD3215 M6x12 C S521 M6x12 A LCD3215 M6x12 C S521 M6x12

D LCD4020 M6x12 A SC40 M6x12 D LCD4020 M6x12 A SC40 M6

x12

D LCD4215 M6x12 A SC46 M6x12 D LCD4215 M6x12 A SC46 M6x12

D LCD4615 M6x12 D V321 M6x12 D LCD4615 M6x12 D V321 M6x12

D LCD4620 M6x12 D V421 M6x12 D LCD4620 M6x12 D V421 M6x12

C LCD5220 M6x12 D V461 M6x12 C LCD5220 M6x12 D V461 M6x

12

D LCD5710 M8x15 B X461HB M6x12 D LCD5710 M8x15 B X461HB M6x12

D M40 M6x12 B X461UN M6x12 D M40 M6x12 B X461UN M6x12

D M46 M6x12 D M46 M6x12

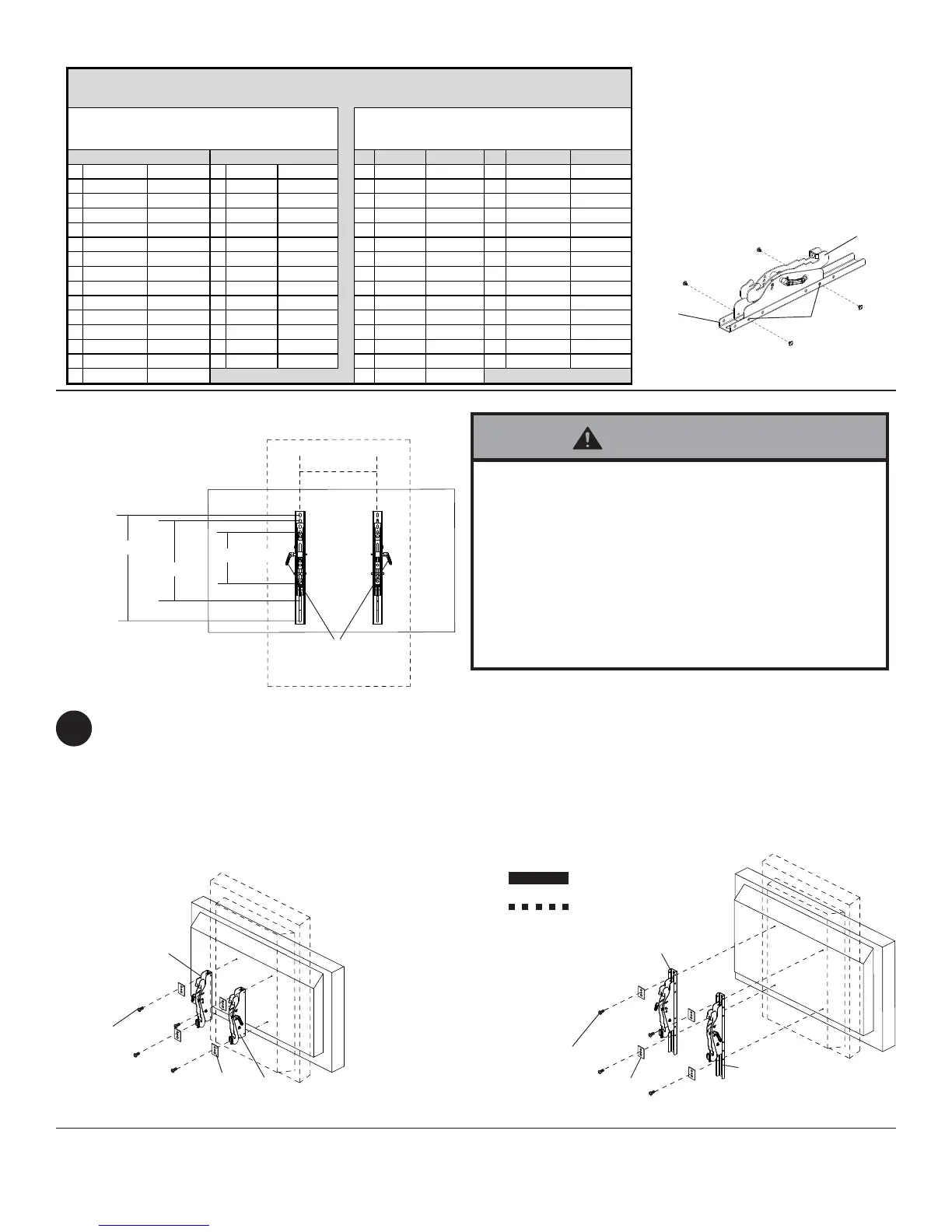

To prevent scratching the screen, set a cloth on a flat, level surface that will support the weight of the screen. Place

screen face side down. If screen has knobs on the back, remove them to allow the tilt brackets to be attached. Place

tilt brackets (B and C) on back of screen as shown in fig. 2.2. Note: Be sure to attach tilt brackets with handles facing

outward as in figure 2.2. Align tilt brackets to screen mounting holes as recommended by chart below. Attach the tilt

brackets to the back of the screen using the appropriate combination of screws, either M6 x 12 mm socket pin screw

(G), M6 x 20 socket pin screw (H) or M8 x 15 mm socket pin screw (J) and multi-washers (I) as shown in figures 2.3

and 2.4. Verify that all holes are properly aligned, and then tighten screws using security allen wrench (F).

2

Installing Tilt Brackets

Use Chart to Determine Orientation and Screws

Portrait

Landscape

USING EXTENTION BRACKETS

USING TILT BRACKETS ONLY

HANDLES

FACE OUT

Secure extension brackets (L) to left

tilt bracket (B) with four M5 x 6 mm

socket pin serrated washer head

screws (K).

Height of tilt brackets may be

adjusted using holes above and

below center mounting location

holes.

NOTE: Repeat using right tilt

bracket (C).

• Tighten screws so adapter brackets are firmly

attached. Do not tighten with excessive force.

Overtightening can cause stress damage to screws,

greatly reducing their holding power and possibly

causing screw heads to become detached. Tighten to

40 in. • lb (4.5 N.M.) maximum torque.

• If screws don't get three complete turns in the screen

inserts or if screws bottom out and bracket is still not

tightly secured, damage may occur to screen or

product may fail.

WARNING

MAX Distance 400 mm

USE TILT BRACKET ONLY

WHEN MOUNTING TO

SCREEN USING 200 X 200

fig 2.4

fig 2.3

fig 2.2

fig 2.1

* Use multi-washers (I) to attach tilt

brackets (B and C) to your screen

when using M6 x 12 mm socket pin

screw (G), M6 x 20 socket pin

screws (H).

M8 screws do not require

multi-washers (I)

G, H

or J

B

C

I*

G, H

or J

I*

B

C

L

K

B

400 mm

200 mm

300 mm

CENTER

MOUNTING

LOCATIONS

Loading...

Loading...