10

When using compressed air or

nitrogen as drive medium, it must be

clean (filtered). Unfiltered air leads to

excessive wear, clogging of the

silencer and complete damage of

the vibrator (seizure of piston).

The compressed air or nitrogen

supply must be reliably fastened.

≤ 5 µm

filter recommended

Please observe already during installation:

The permissible temperature range must not be exceeded or fallen short

of during operation, see Chapt. 4 „Safety – Permissible Operating

Conditions“.

Versions for other temperature ranges on request.

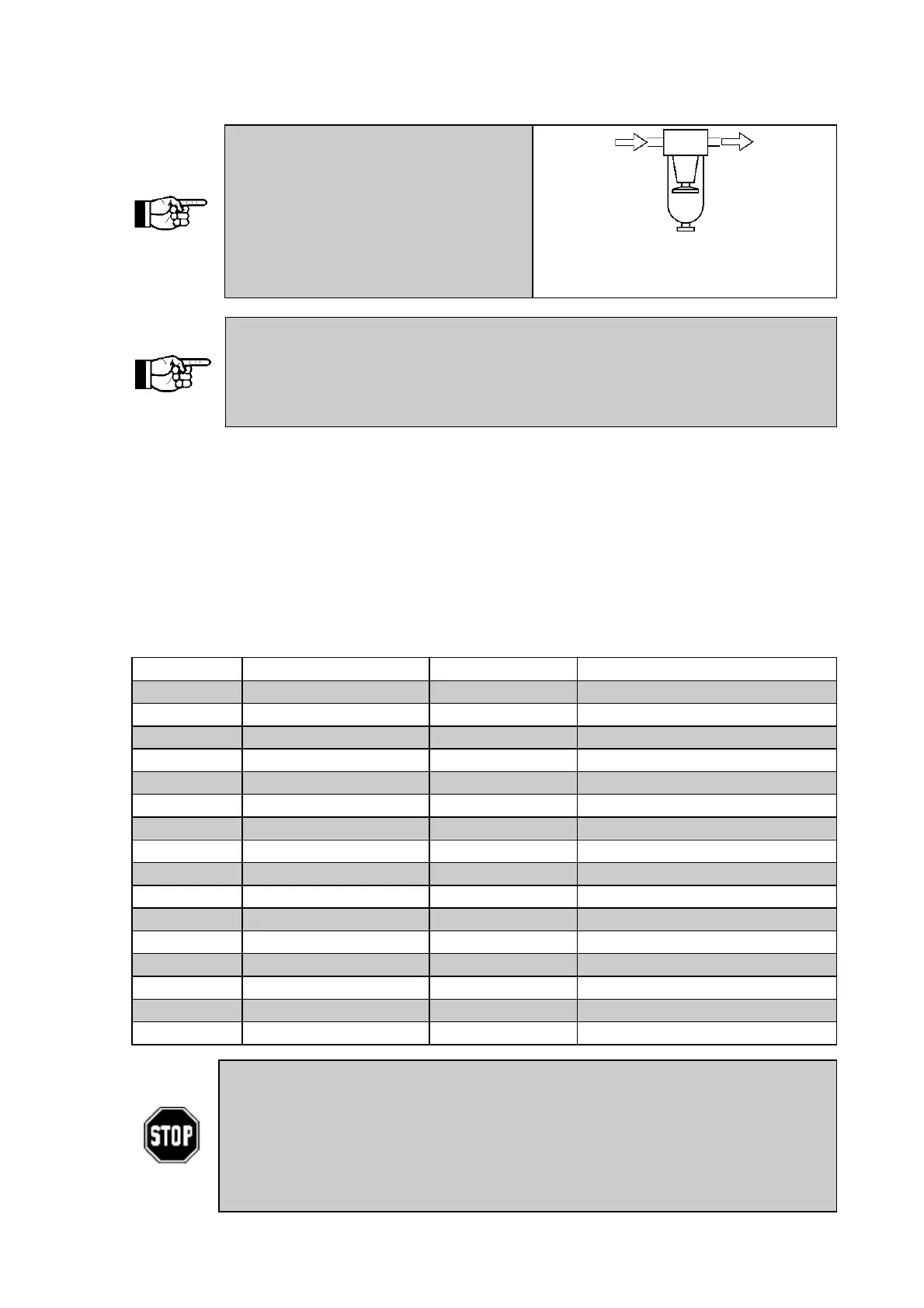

Air supply line:

The pressure drop increases with the

hose length. The nominal widths in the

table apply for hose lengths of up to 3

m. Longer supply lines need bigger

cross-sections.

Air discharge line:

Exhaust air can be discharged through

a hose.

If full power of the linear vibrator is

required, the air discharge hose must

have a bigger cross-section than the

air supply hose. The free end should

be fitted with a silencer.

Minimum cross-sections for valves and hoses:

Type Connection threads Hose size 3/2-way valve (size)

NTS 100/01 G 1/4 NW 10 G 1/4 NW 6

NTS 75/01 G 1/4 NW 10 G 1/4 NW 6

NTS 50/01 G 1/4 NW 10 G 1/4 NW 6

NTS 70/02 G 3/8 NW 12 G 1/4-3/8 NW 7

NTS 54/02 G 3/8 NW 12 G 1/4-3/8 NW 7

NTS 50/04 G 3/8 NW 12 G 3/8-1/2 NW 9-12

NTS 21/04 G 3/8 NW 12 G 3/8-1/2 NW 9-12

NTS 50/08 G 3/8 NW 12 G 3/8-1/2 NW 9-12

NTS 50/10 G 1/2 NW 13 G 1/2 NW 12

NTS 30/10 G 1/2 NW 13 G 1/2 NW 12

NTS 50/15 G 3/4 NW 19 G 3/4 NW 19

NTS 50/20 G 3/4 NW 19 G 3/4 NW 19

NTS 30/20 G 3/4 NW 19 G 3/4 NW 19

NTS 24/20 G 3/4 NW 19 G 3/4 NW 19

NTS 50/40 G 1 NW 25 G 1 NW 25

NTS 20/40 G 1 NW 25 G 1 NW 25

Do not use fittings with threads longer than specified (e.g. no tubes with

male thread). The housing may thereby be deformed – the piston will

seize.

Make sure that no Teflon tape will enter into the unit. This would cause

seizure. The first two windings of the thread should remain free!

The base plate must have full contact. Otherwise the housing may warp

and the unit will not start.

Loading...

Loading...