9

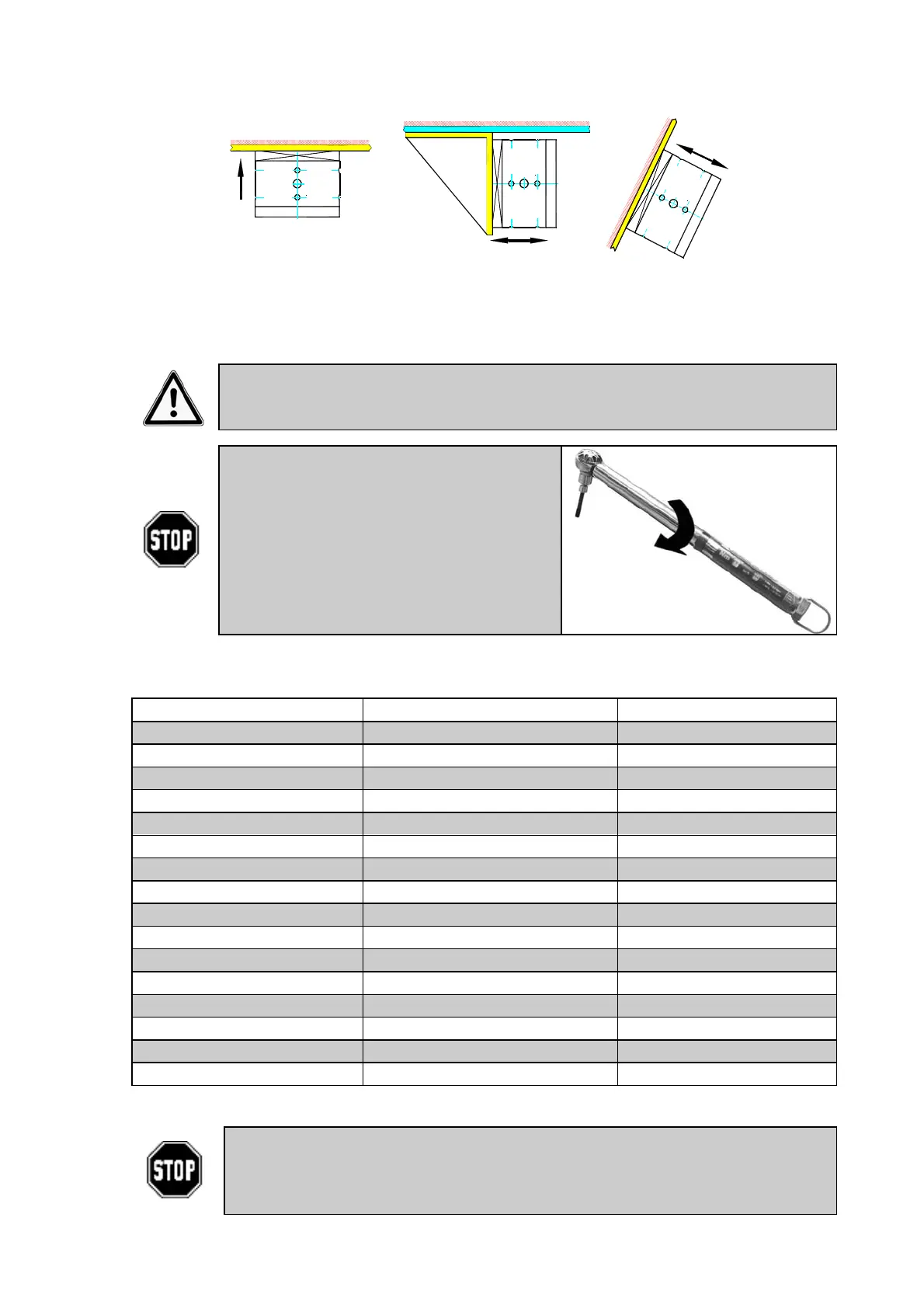

A B

C

The illustrations show possible applications:

A on vibrating tables for compaction, testing etc.

B under tables, on filters etc. for shaking

C on bunkers for emptying, on vibrating troughs and sieves

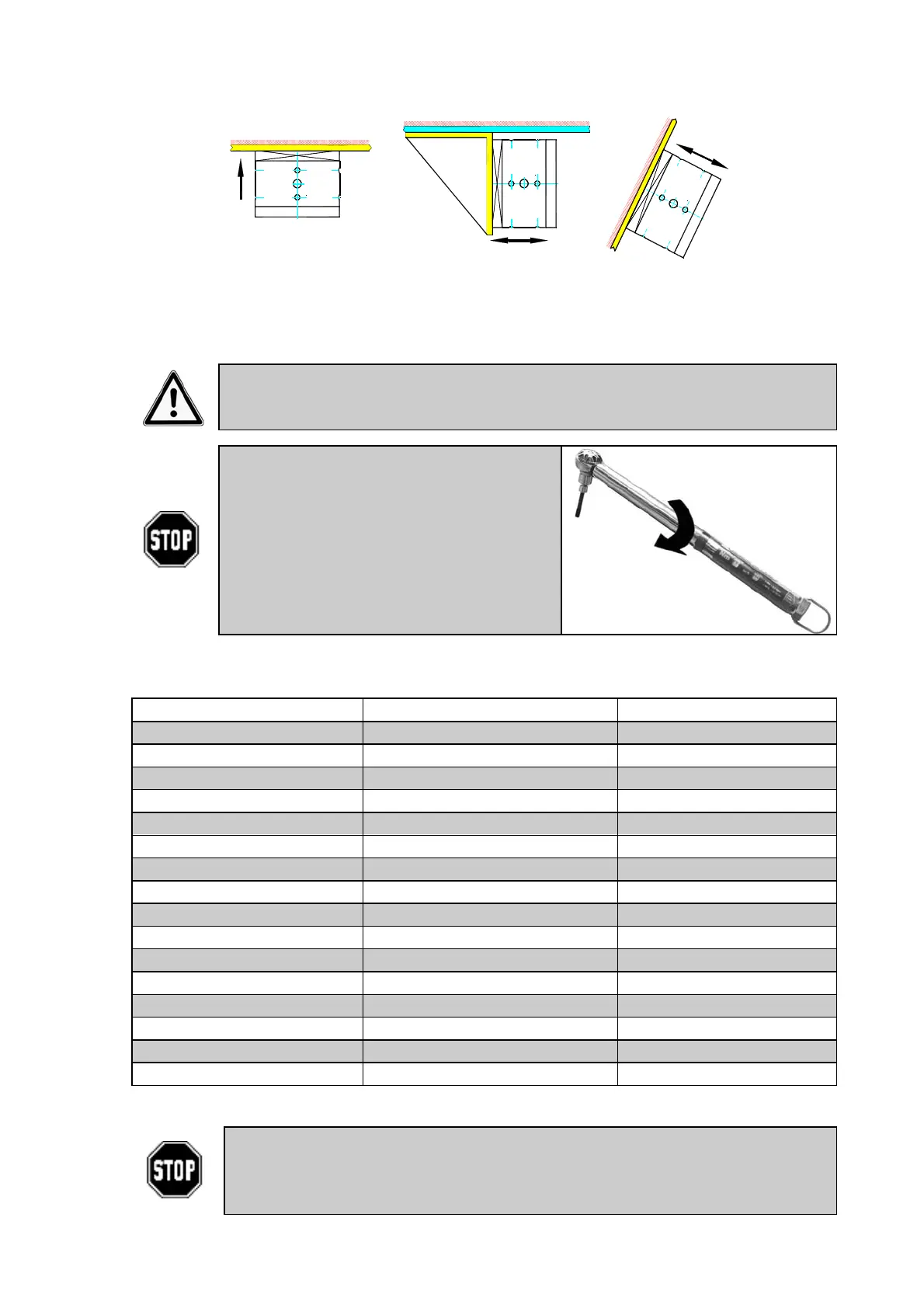

As a protection against loosening use self-locking screws and nuts, self-

locking lock washers (no spring rings) or use a liquid screw retention

agent, e.g. Loctite 270.

The tightening torques can be taken

from the following table. Higher

tightening torques may cause fracture

of screws or tearing of threads.

Inadequate screw connections may

cause loosening of units by vibration.

This can cause damage to persons and

material!

Recommended average tightening torques for property class 8.8 screws

(screws as delivered, without additional lubrication):

Type Thread Tightening torque

NTS 100/01 M 12 30 Nm

NTS 75/01 M 8 25 Nm

NTS 50/01 M 8 25 Nm

NTS 70/02 M 8 25 Nm

NTS 54/02 M 8 25 Nm

NTS 50/04 M 12 87 Nm

NTS 21/04 M 12 87 Nm

NTS 50/08 M 16 215 Nm

NTS 50/10 M 16 215 Nm

NTS 30/10 M 16 215 Nm

NTS 50/30 M 16 215 Nm

NTS 50/20 M 20 430 Nm

NTS 30/20 M 20 430 Nm

NTS 24/20 M 20 430 Nm

NTS 50/40 M 24 740 Nm

NTS 20/40 M 24 740 Nm

Use a torque wrench and tighten the screws in a crosswise pattern.

Retightening:

Screw connections must be checked and, if necessary, retightened after

1 hour of operation (after initial start-up) and then at regular intervals

(normally each month).

Loading...

Loading...