SECTION 35 - HYDRAULIC SYSTEM

35-87

REINSTALLATION

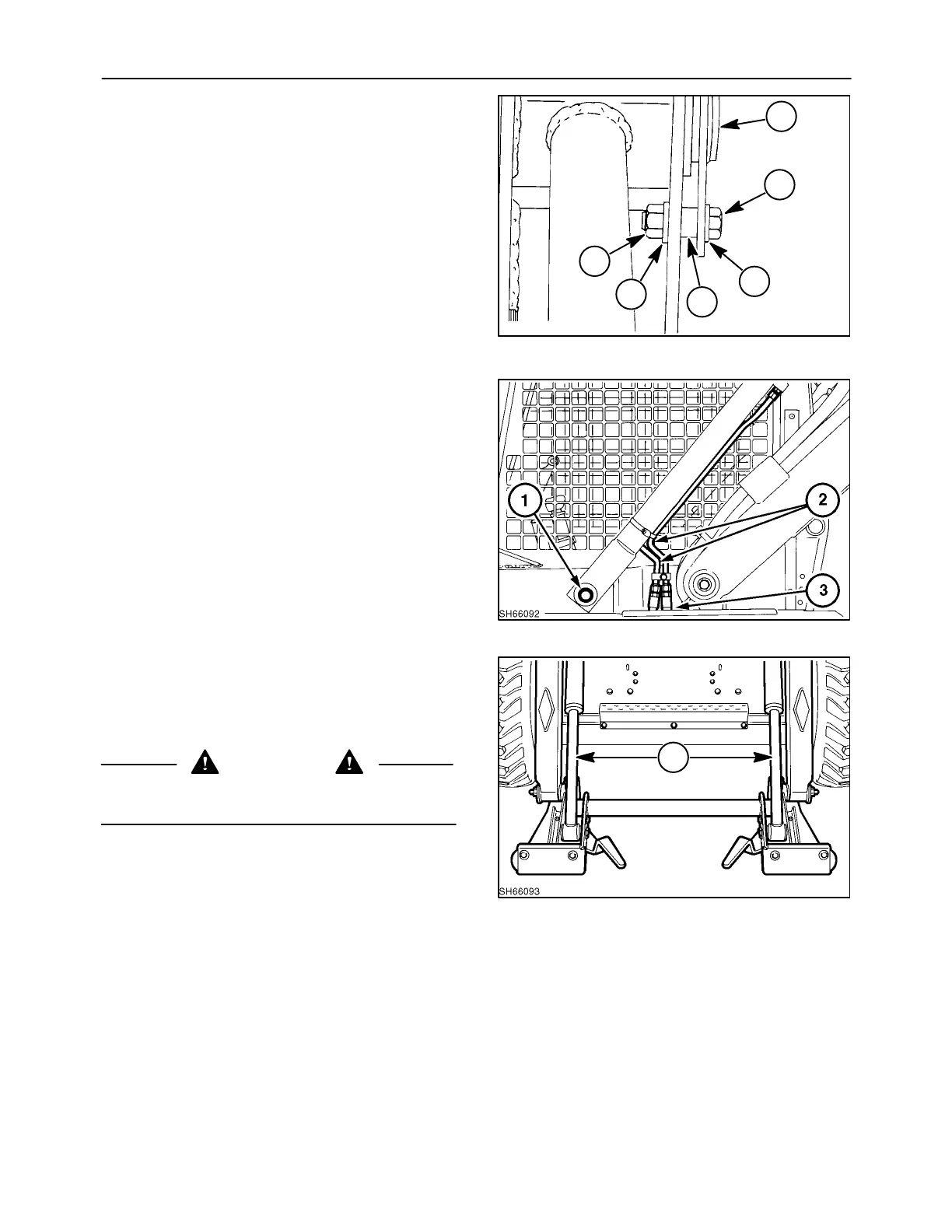

1. Lubricate the boom pivot pins, 1, with an anti-

seize-type lubricant.

2. Install the cylinder onto the loader.

NOTE: Refer to Service Bulletins 5/96 - I6 and 7/96

- I6 for updated pivot pin support information and

proper pin, spacer, and bolt part numbers.

3. Install a 3/8″ bolt, 2; flat washer, 3; and spacer, 4,

through the pivot pin retaining strap and boom

side plate. Secure with flat washer, 5, and lock-

nut, 6.

4. Torque the upper pivot pin hardware to 38 N·m

(28 ft. lbs.).

2

1

19997745

4

3

6

5

152

5. Torque the lower pivot pin hardware, 1, to 338

N·m (250 ft. lbs.).

6. With a six-pound hammer and using a piece of 2

x 4 hardwood to protect the pin, hit the pivot pin

and retaining hardware to properly seat the ta-

pered pin and retorque to 338 N·m (250 ft. lbs.).

7. Reinstall lines, 2, and position to prevent contact

with other components, fenders, etc. at 3.

8. Reinstall the plastic plug into the cap inner shell.

9. Cycle the boom several times to remove the air

from the system and check the cylinder for leaks.

153

BUCKET CYLINDER

Op. 35 710 10

REMOVAL

CAUTION

Never loosen any hydraulic lines without first

relieving all pressure in the system.

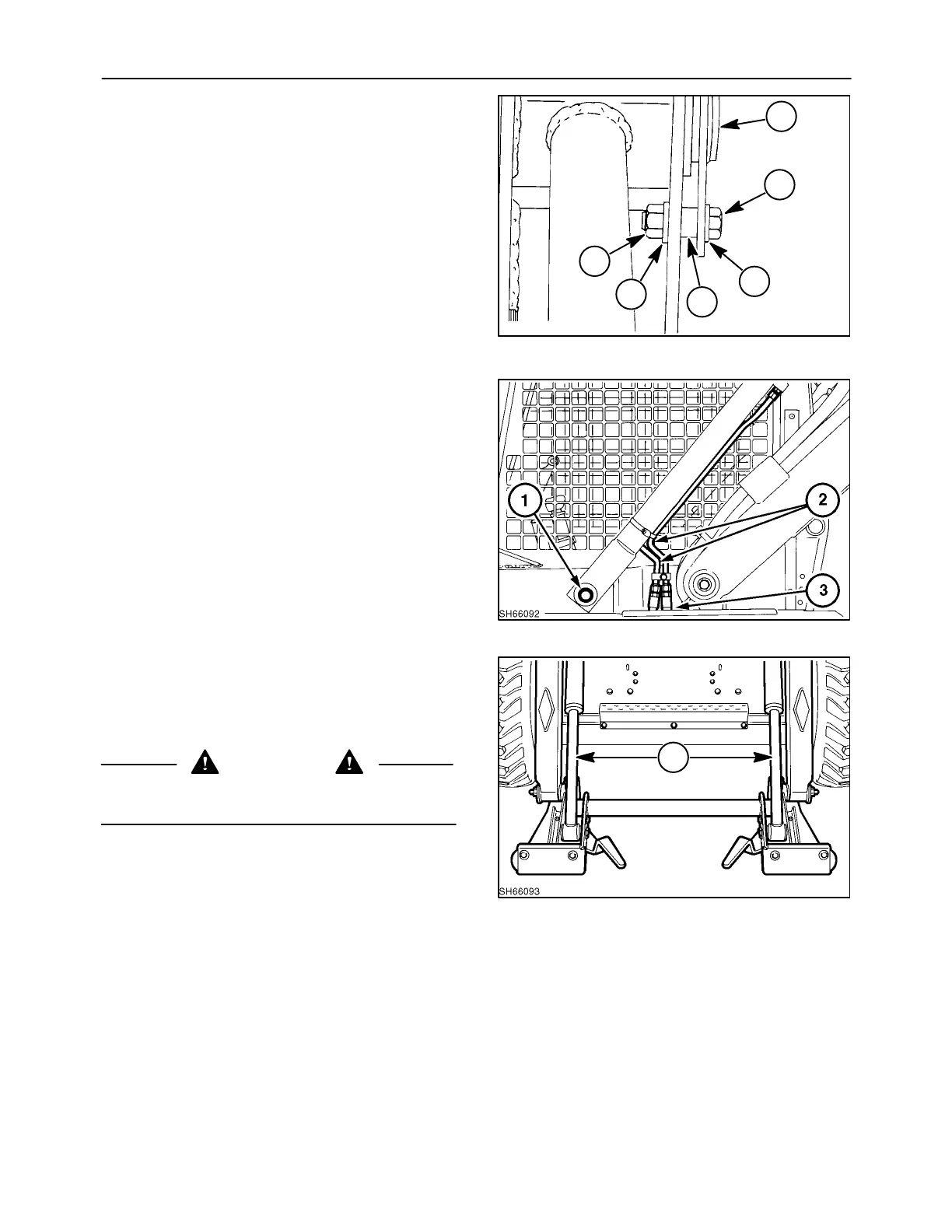

1. Remove any attachment, bucket, etc. from the

boom attaching plate and lower the boom to the

lowered position.

2. Extend the cylinders, 1, to the fully extended

position.

3. After stopping the engine and before removing

the seat belt and dismounting from the loader,

turn the ignition switch to the “RUN” position.

4. Push both the boom and bucket pedals to relieve

all residual hydraulic pressure in both circuits.

5. Turn off the ignition switch.

1

154

Loading...

Loading...