NIBCO INC. WORLD HEADQUARTERS • 1516 MIDDLEBURY ST. • ELKHART, IN 46516-4740 • USA • PH: 1.800.234.0227

TECH SERVICES PH: 1.888.446.4226 • FAX: 1.888.336.4226 • INTERNATIONAL OFFICE PH: +1.574.295.3327 • FAX: +1.574.295.3455

www.nibco.com

8

www.nibco.com

AHEAD OF THE FLOW

®

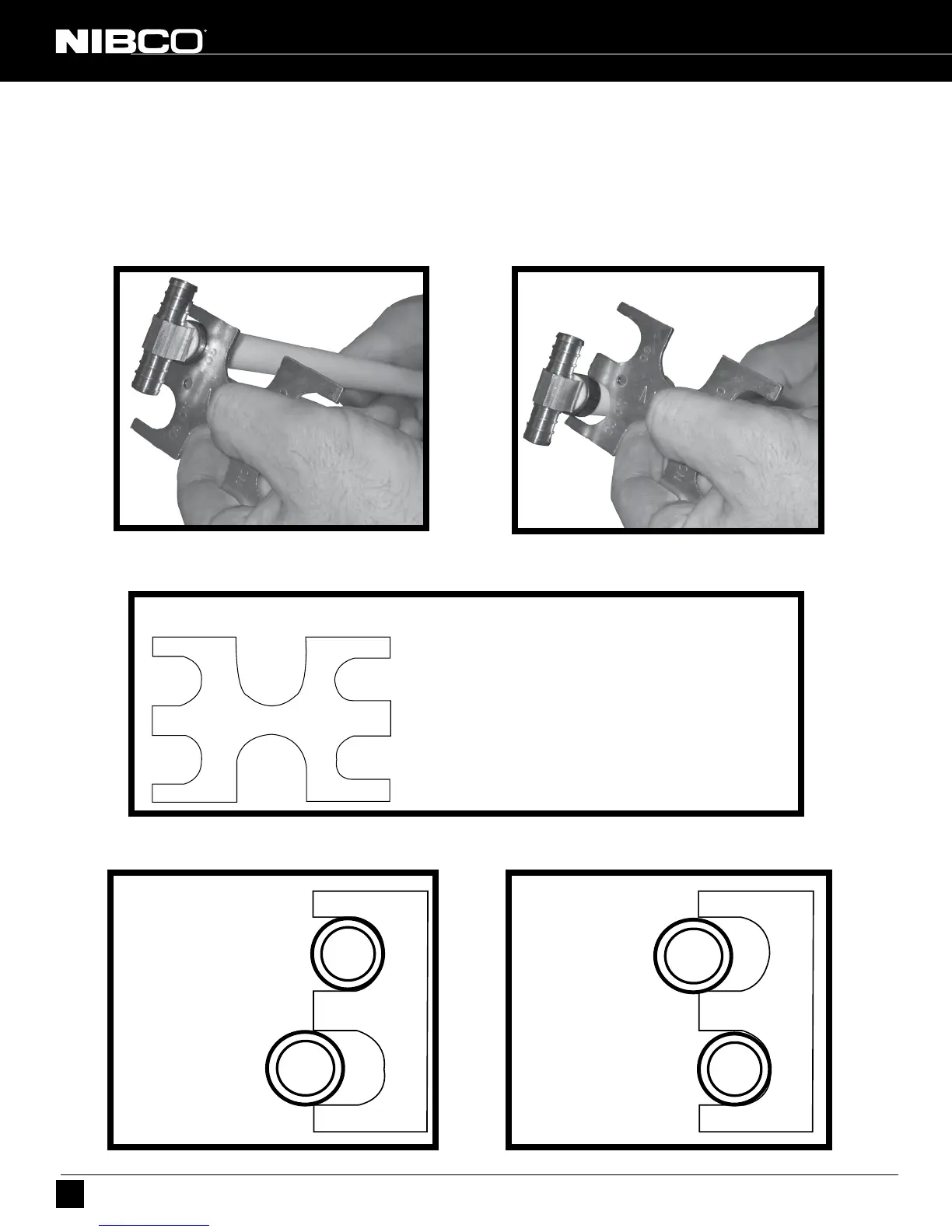

Step 5

Use the go/no-go gauge to check every crimp joint. An improper crimp has been formed when (1) the “go” side does not fit over the ring

or, (2) the “no” side does fit over the ring. If the joint fails either of these two tests then cut out the joint and return to Step 1.

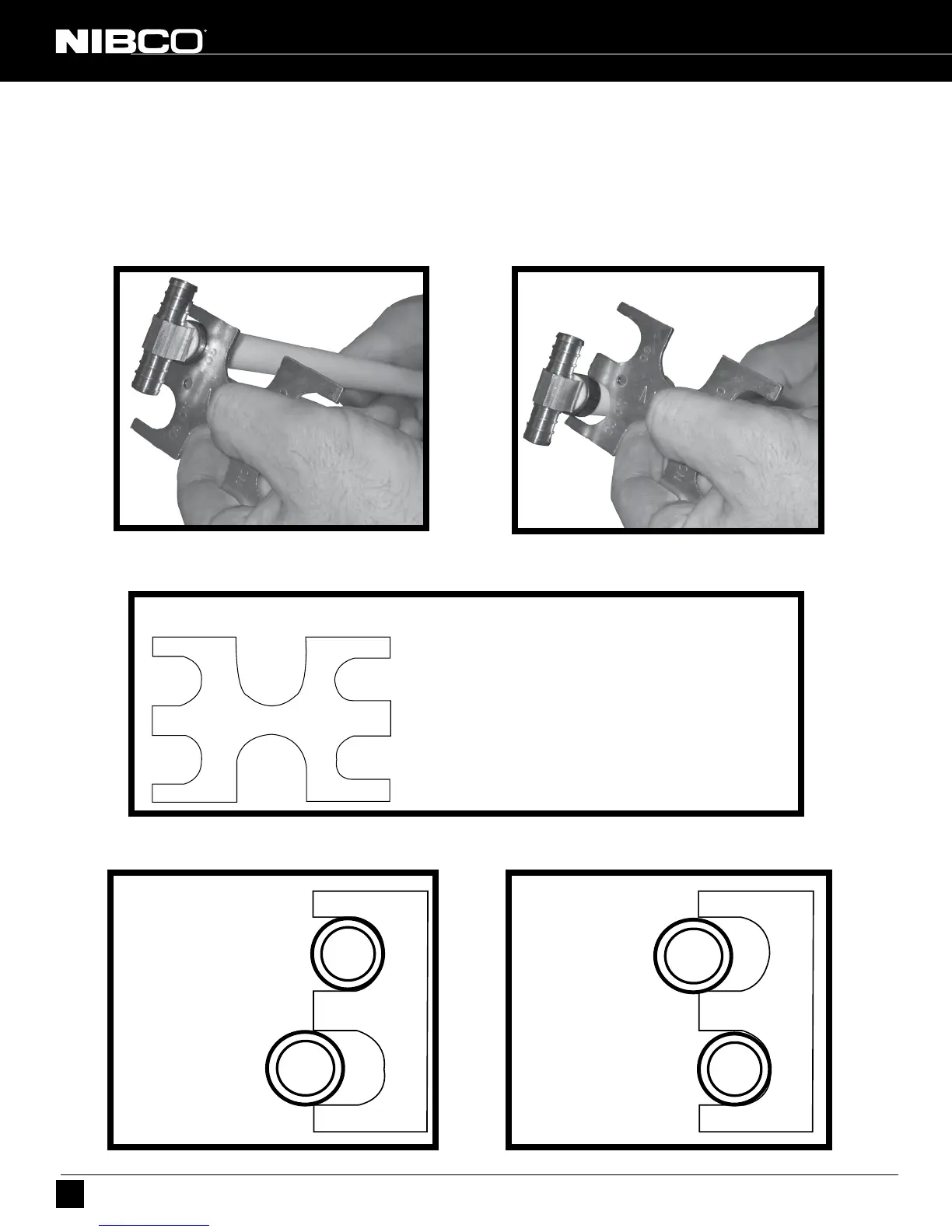

CRIMP GAUGE

No-go

No-go No-go

Go

Go

Go

BAD CRIMPS

Ring is compressed

too much.

Ring is not

compressed

sufficiently.

No

Go

Go

A micrometer can be used to measure the correct

dimensions of a crimp ring after a proper, single

crimp per the following table:

Tube Size Min Max

3/8” 0.580” 0.595”

1/2” 0.700” 0.715”

3/4” 0.945” 0.960”

1” 1.175” 1.190”

1-1/4” 1.430” 1.445”

GOOD CRIMPS

Ring is properly

compressed.

Does not fit in

“No-Go” slot.

Ring fits in

“Go” slot.

No

Go

Go

AND

Loading...

Loading...