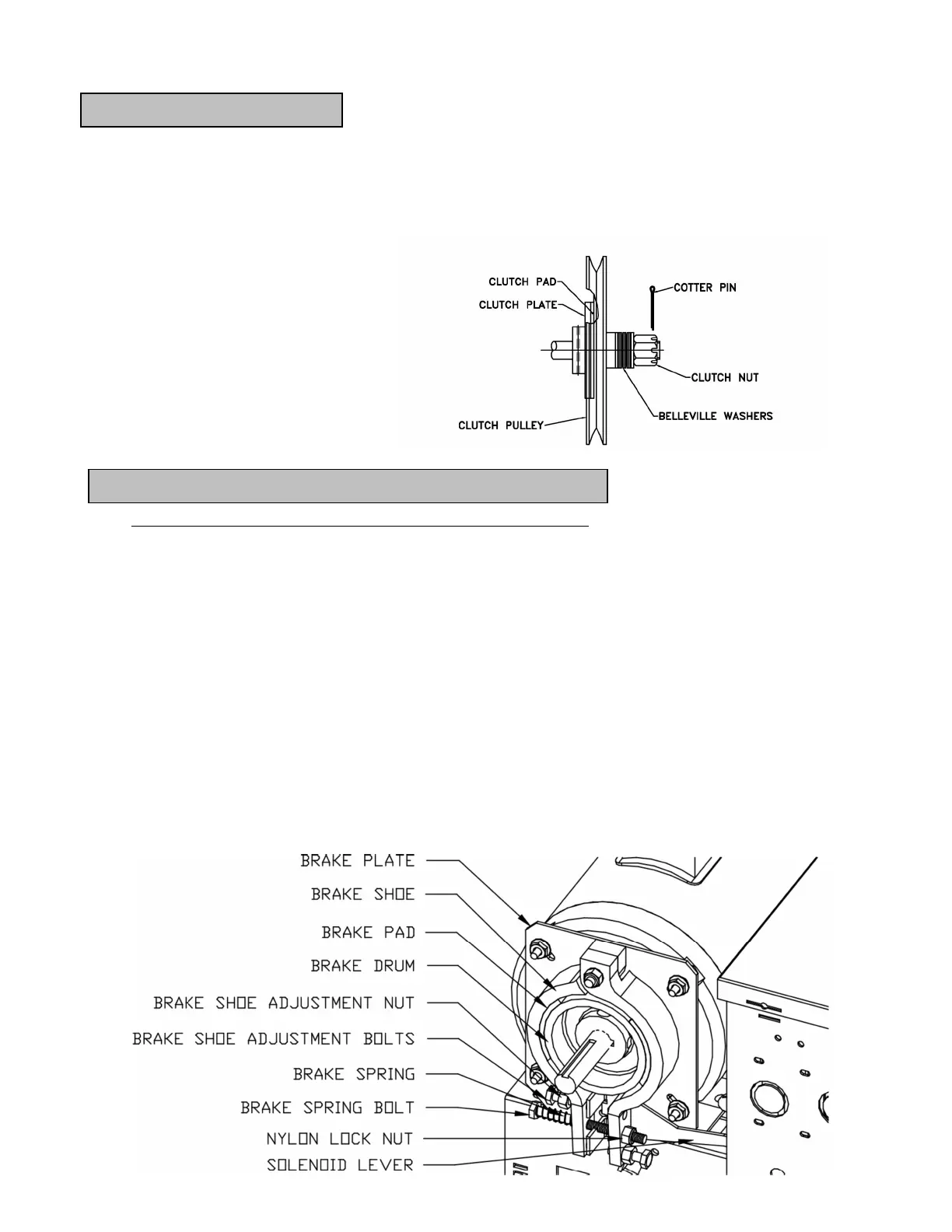

. emove cotter pin tapped to pulley.

. otate clutch nut counterclockwise loosen until there is insufficient tension to permit clutch to drive door.

. radually tighten clutch nut until the tension on belleville washers is sufficient to permit clutch to drive door

smoothly but will allow clutch to slip if door is obstructed. It should be possible to stop moving door by hand if

clutch is properly adusted.

. ock clutch nut in place by inserting cotter pin into one of the

two adustment holes provided.

Caution o not over-tighten the clutch as this

will cause damage to the washers

and create adustment problems.

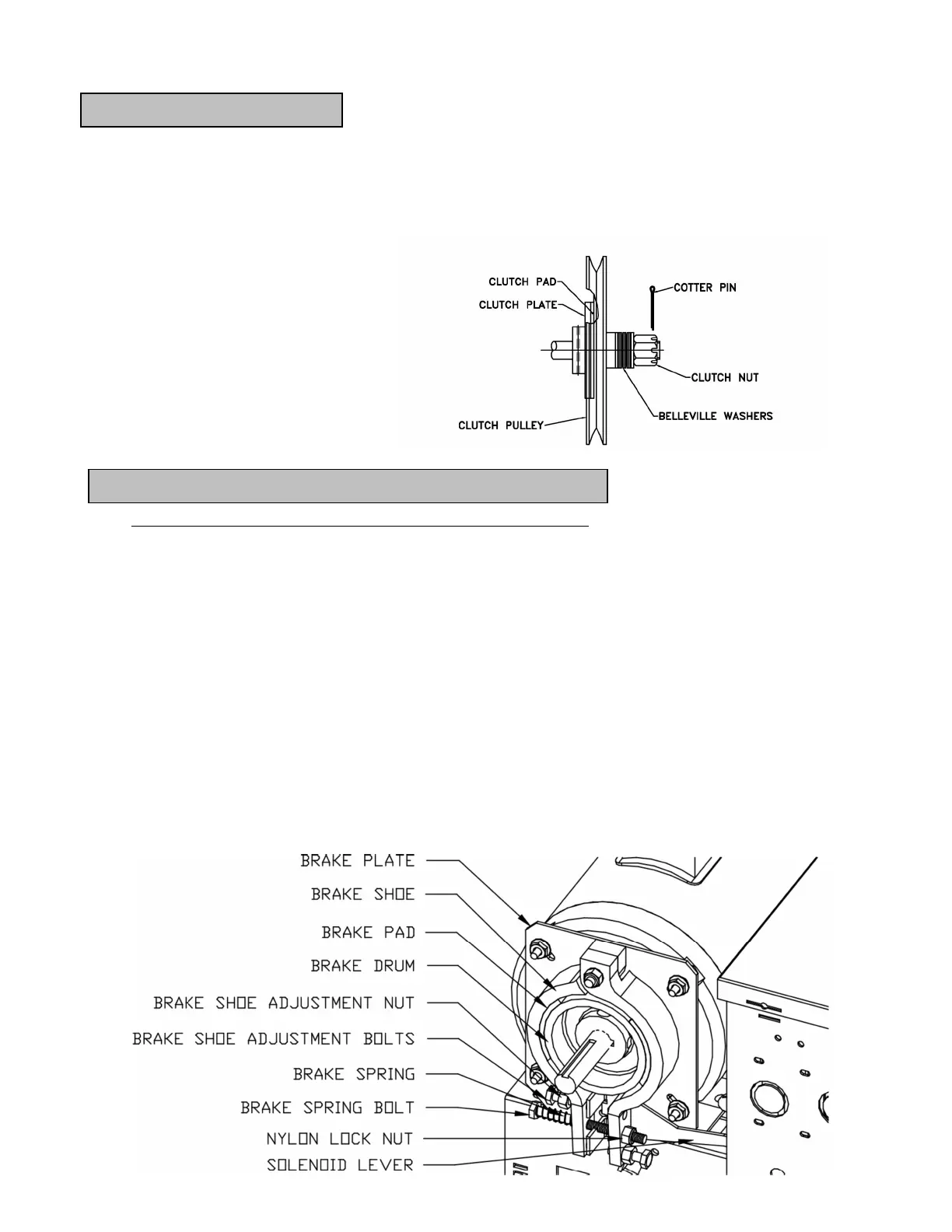

If your operator was ordered with an optional solenoid brake system

The brake adustment is factory set and should only reuire minor adustment after extensive use.

erify brake adustment by manually holding in solenoid plunger. hen brake is properly adusted, the brake

shoe pads should make complete contact with brake drum with sufficient brake spring tension to stop and

maintain door when solenoid is de-energied. hen solenoid is energied, brake shoes should release from

drum with sufficient clearance to avoid contact between shoes and drum.

To adust brake tension, tighten to increase or loosen to decrease nylon lock nut on brake spring bolt.

bserve solenoid during electrical testing of brake. rake spring tension must be adusted so that solenoid

should pull and release smoothly and uietly. Too much or too little tension on brake spring may cause solenoid

to burn out.

To adust individual brake shoes, loosen nut on brake shoe adustment bolt and adust bolt. hen properly

adusted, there should be a small clearance between adustment bolt and solenoid bracket when solenoid is de-

energied. hen solenoid is energied, brake shoes should move away from drum with sufficient clearance to

avoid friction between brake shoe pad and drum. After adustments are made be sure to tighten nuts on brake

shoe adustment bolts.

CTC ASTMENT

AE ASTMENT - or Models

Loading...

Loading...