- 7 -

MAINTENANCE

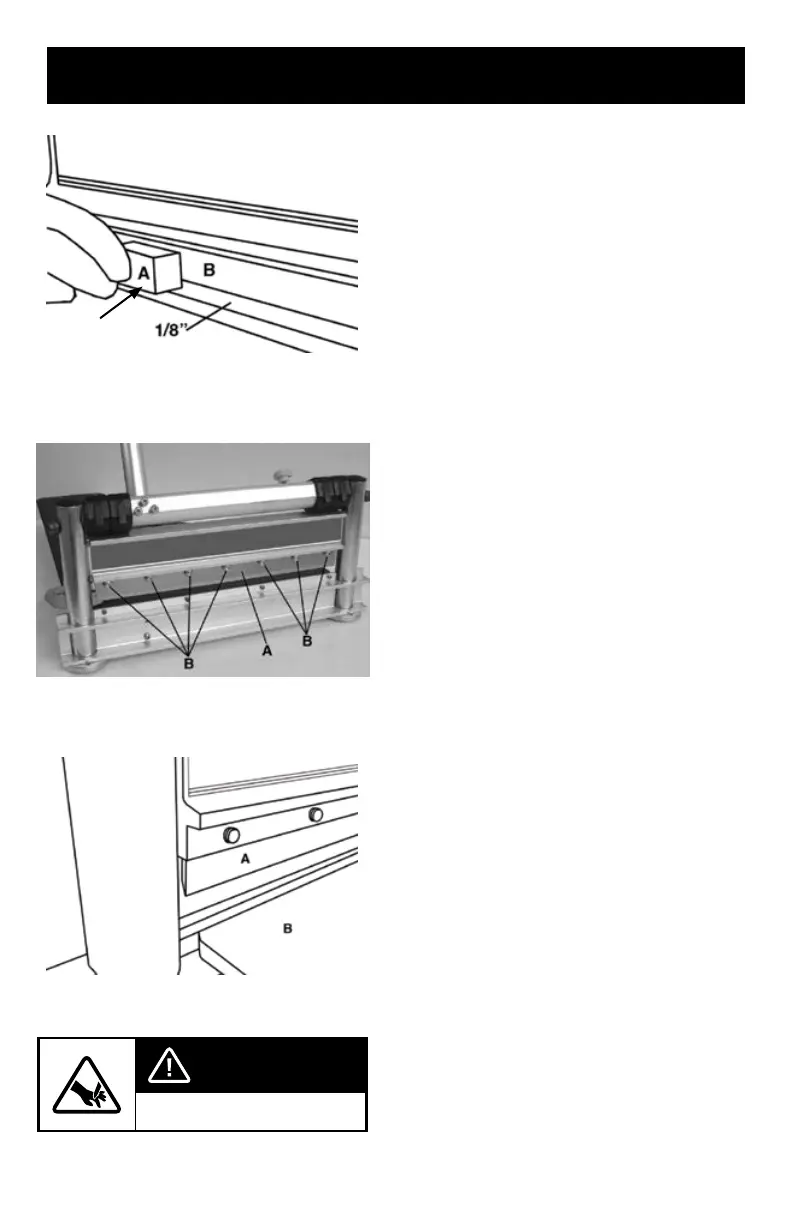

Removing burrs from the flat edge of the

blade is very important, honing a new blade

should be done after the first 40-100 cuts,

after every 100+ cuts and when the blade

has been re-sharpened.

With the blade (Fig. 10-B) installed and

positioned roughly 1/8” above the table top,

lay the flat side of your honing stone

(Fig. 10-A) against the flat side of the blade.

Move the honing stone from one end to

the other a few times until burr has been

removed.

The included blade can be sharpened.

Only the beveled edge of the blade must

besharpened. The flat edge of the blade

must remain flat. We recommend that

this operation be done by a qualified

professional.

WARNING! Blade is very sharp. Wear gloves

when handling blade.

To prevent surface corrosion, it is

recommended to apply a small amount of

light machine oil on the sliding parts of the

laminate cutter. Lubrication should be done

once every two months or once a month if

working in dirty or dusty conditions.

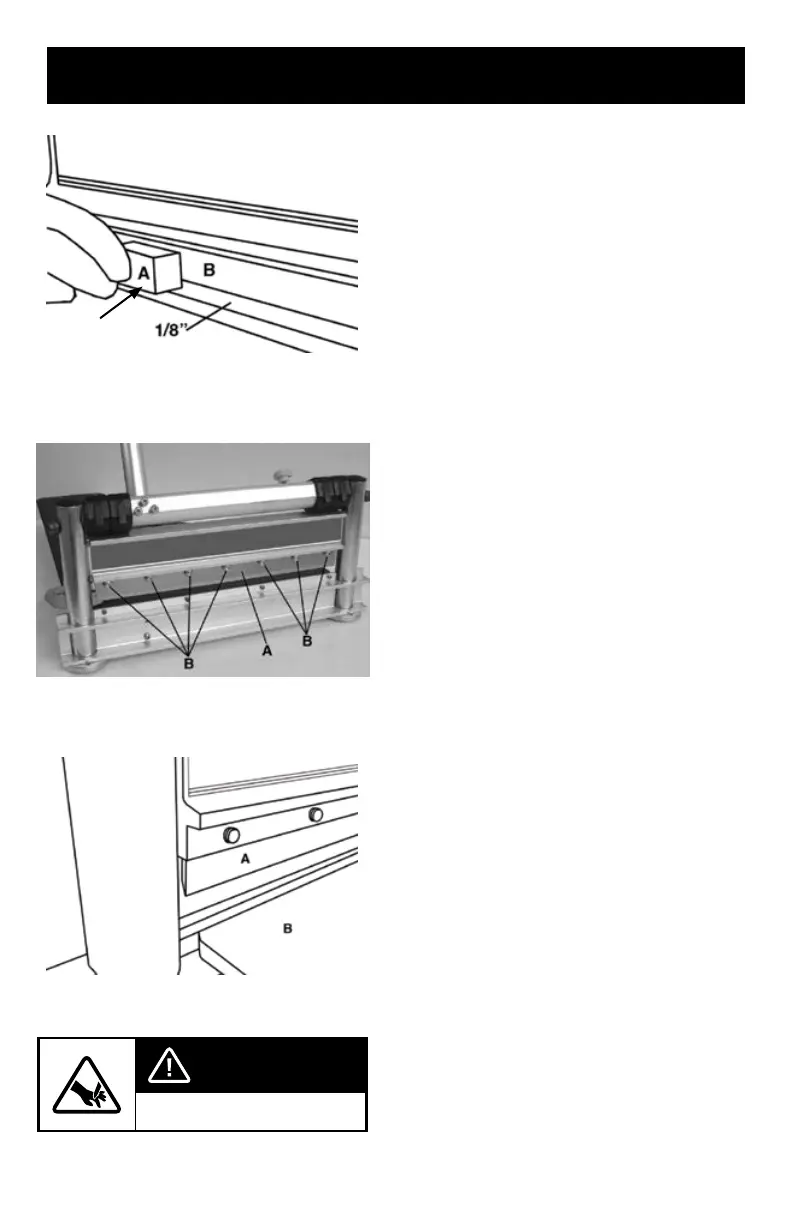

1. To remove the blade (Fig. 11-A), remove

the seven allen head screws (Fig. 11-B)

using the supplied hex key. Carefully

remove the blade.

2. Once blade has been sharpened or

replaced, it can be re-installed. Position

the blade (Fig. 12-1) with its flat edge

facing the table (Fig. 12-B). Make sure

the mounting surface and blade are

clean, re-install the blade with the seven

allen head screws removed earlier using

the supplied hex key.

HONING BLADE

(HONING STONE NOT INCLUDED)

SHARPENING OR REPLACING BLADE

LUBRICATION

FIGURE 12

WARNING

VERY SHARP BLADE

FIGURE 10

FIGURE 11

NORSKE

HONING STONE:

NMAP005

Loading...

Loading...