408A Manual

clock, the distortion may be unacceptable. There-

fore, the output is limited to approximately 40% of

the system clock and steep output filters are pro-

vided on board: in this case 7th-order elliptical low

pass filters.

5.6 If you are using an external clock and a Kp

which give a clock substantially lower than the

281.47MHz default internal clock, you may need to

filter the Sine and Cosine Outputs to obtain accept-

able distortion for your application. For best perfor-

mance, set the corner frequency at 40% or less of

your external clock frequency times Kp. The lower

your filter as a percentage of your clock frequency,

the lower the distortion.

NOTE:

Since filtering occurs before the signal is level

shifted to ACMOS/TTL, the ACMOS/TTL output

may be erratic or distorted when using low clock

frequencies. If you require an ACMOS/TTL level

signal when using low clock frequencies, it is

recommended that you use an external comparator/

level shifter connected to the output of your external

filter. Contact Novatech Instruments if you require

application assistance.

5.7 For example, if you are using a 10MHz external

clock, with the default reference multiplier (Kp) of

10, then the internal clock is 100MHz. An optimal

filter for this frequency would then be approxi-

mately 40MHz (40% of 100MHz).

5.8 In amplitude modulation (the “Z” command),

the modulation frequency is derived from the micro-

controller clock and is asynchronous to the carrier.

The modulation signal is unfiltered and is a stepwise

approximation to a sine wave.

6.1 Install the 408A as directed in the Serial Opera-

ti

on part of Section 3. Connect your host controller

and operate the 408A per Section 4. The test limits

assume a stable environment of 18-28

o

C.

6.2 The performance test detailed below verifies

each functional block on the 408A.

NOVATECH INSTRUMENTS

Allow the 408A to warm up for at least 15 minutes

before performing any measurements. For best

results, the 408A should be verified in its installed

environment.

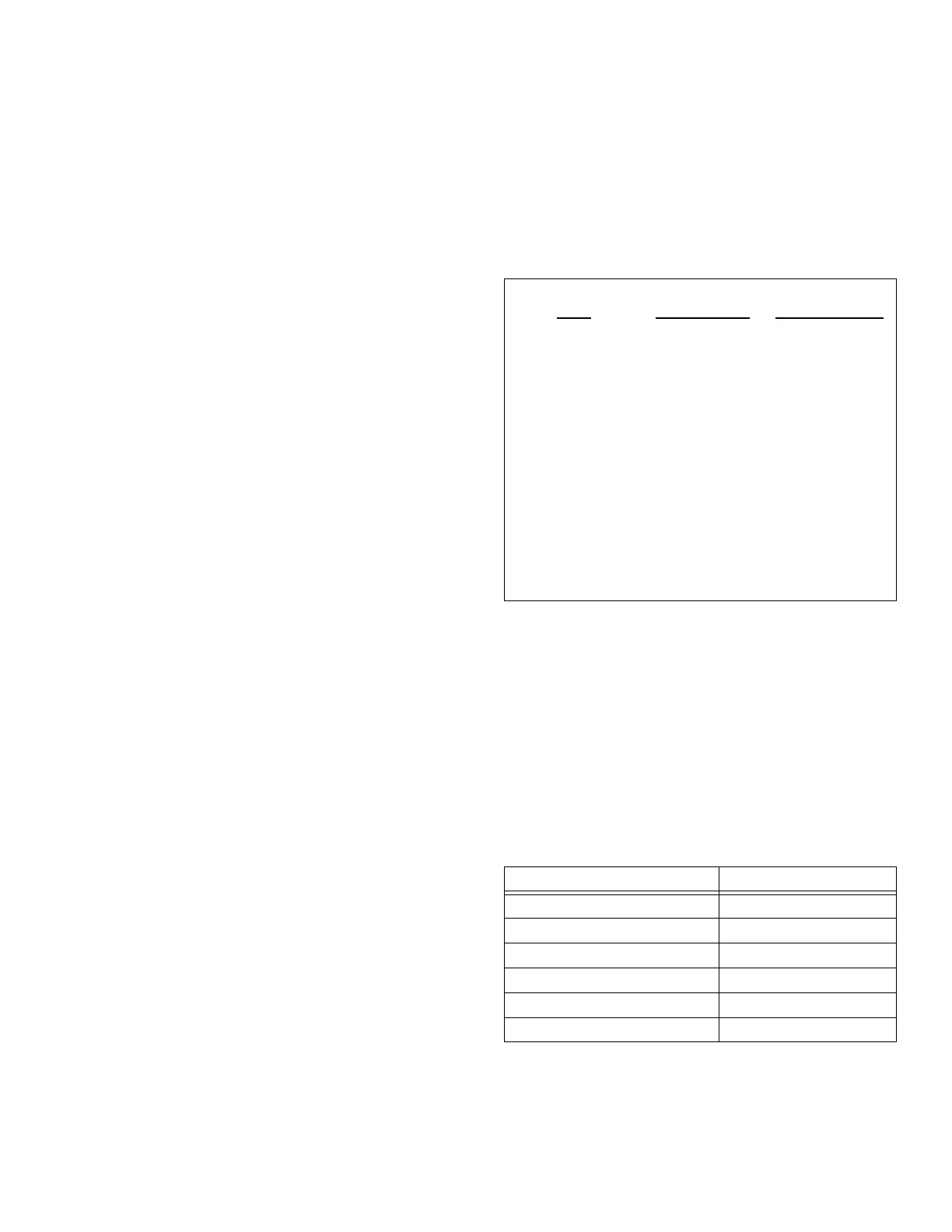

6.3 See Table 8 for a list of recommended test

equipment to perform the following measurements.

6.4

Verify Frequency Accuracy.

To verify the fre-

quency of the 408A, set the output sequentially to

each value in Table 9. Connect the recommended

frequency counter set to 50Ω termination and 1Hz

resolution. Verify the limits show in Table 9. Test

Sine (Q) Out, Cosine (I) Out and ACMOS Out to

verify functionality of all outputs. If you do not use

an external reference for the frequency counter, be

sure to add the error of your counter to the tolerance.

(LSD =

east

ignificant

igit on counter).

6.5

Sine (Q) Out Amplitude Verification.

Set the

frequency of the 408A to 100kHz. Connect the

408A to the DMM through a 50Ω feedthrough ter-

Table 8: Recommended Test Equipment

Oscilloscope 300MHz, 50

Ω

Tektronix

TDS3032

RF Probe 100kHz-

100MHz

Tektronix P6420

or HP34301A

DMM ACrms, dB HP34401A

50

Ω

Termination 50

Ω

,

1% Tektronix

011-0049-01

Frequency

Counter

120MHz HP53132A

Counter Time

Base

<

0.1ppm Novatech

Instruments

Model 2960AR

Table 9: Frequency Test Points

100 kHz

0.1Hz

1 LSD

1 MHz

1Hz

1 LSD

10 MHz

10Hz

1 LSD

30 MHz

30Hz

LSD

50 MHz

50Hz

1 LSD

99 MHz

99Hz

1 LSD

Loading...

Loading...