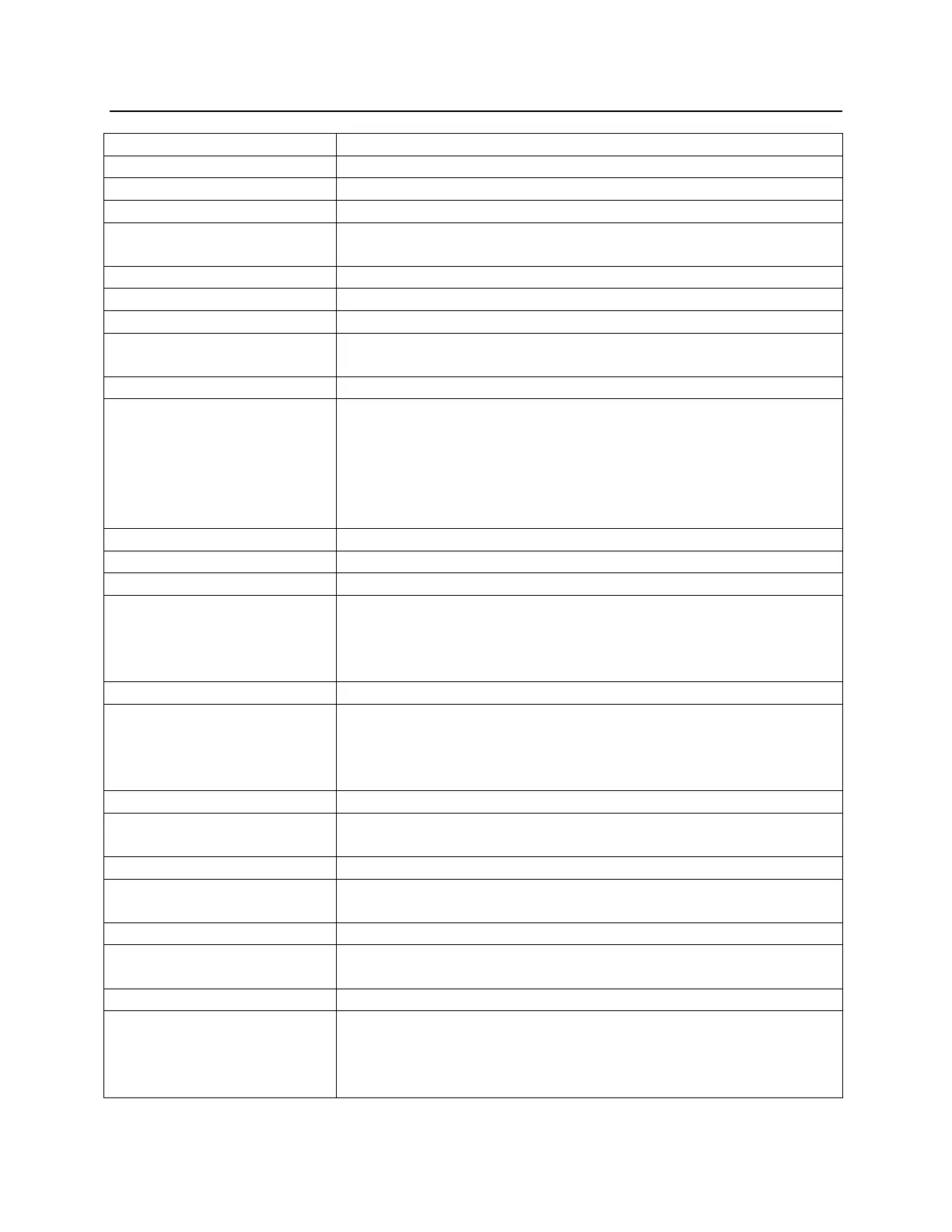

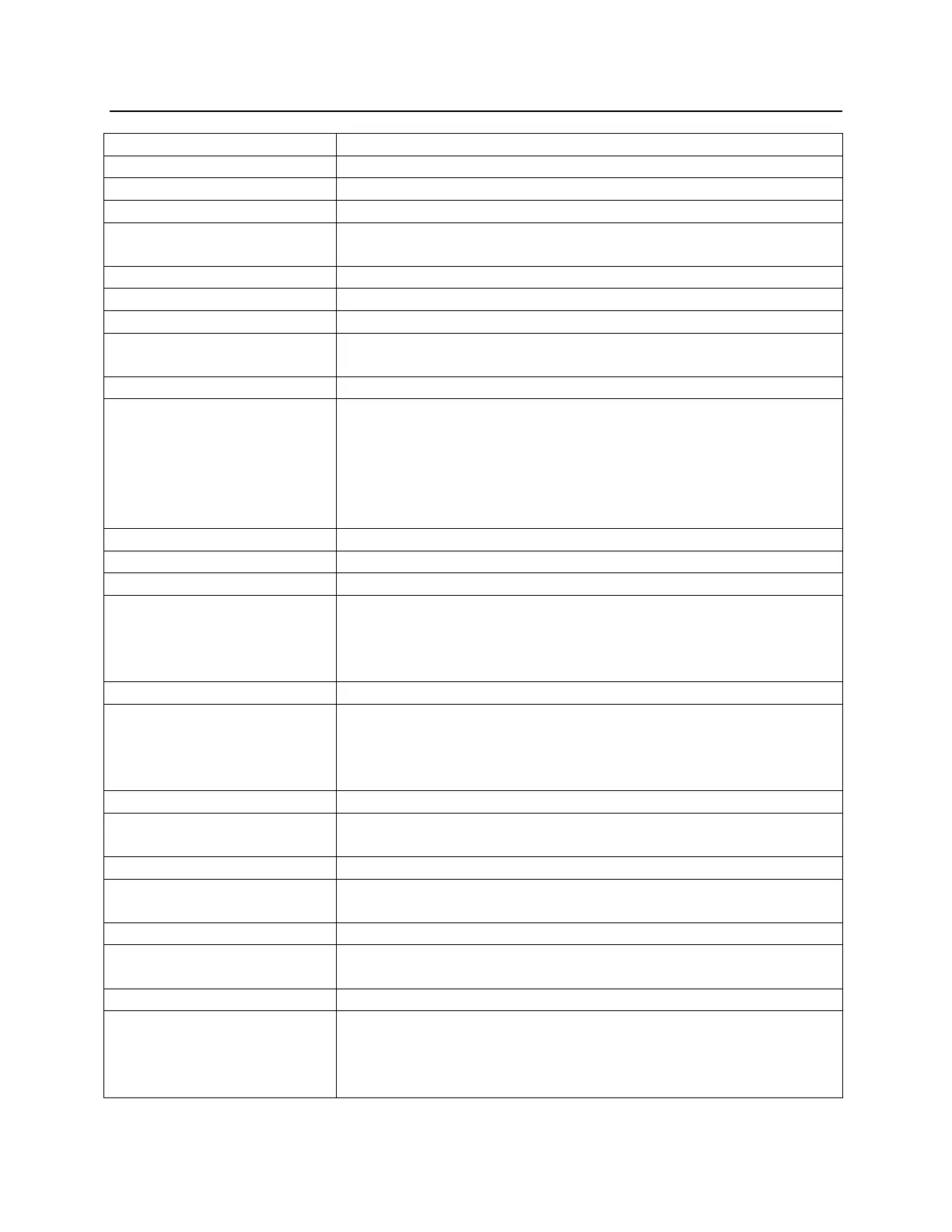

LUBRICANT TERMS AND DEFINITIONS

The ability of grease, gear lubricant or oil to cling to metal.

Used to help combat metal-to-metal contact, thus reducing

wear.

Air pockets in the oil circuit (as at the pump inlet).

The ability of grease, gear lube or oil to cling to itself, thus

resisting tearing apart.

Consistency of grease is its hardness or firmness. It is

determined by the depth in millimeters to which the cone of

a penetrometer sinks into a sample under specified

conditions. Consistency of grease may be influenced by

the type and amount of thickener, viscosity of oil, working

and other factors.

Foreign material that could damage a part.

Film strength is defined as the tendency of oil molecules to

cling together. It is the ability of those molecules to resist

separation under pressure between two metals and to hold

these metal surfaces apart.

A push or pull acting upon a body. In a hydraulic cylinder,

it is the product of the pressure on the fluid, multiplied by

the effective area of the cylinder piston. It is measured in

pounds or tons.

The resistance to fluid flow in a hydraulic system. (An

energy loss in terms of power output.)

Surface damage on mating, moving metal parts due to

friction. A severe form of adhesive wear.

Use of a substance (grease, oil, etc.) to reduce friction

between parts or objects that move against each other.

A rating given to a grease from the National Lubricating

Grease Institute. This rating determines the hardness of

the grease and goes from a 000 to a 6 rating. Most

greases are NLGI #2 rated.

Loading...

Loading...