General Venting │ Vmax I&O Manual

Stainless Steel Piping – The Vmax universal appliance adapter is designed to connect directly to DuraVent –

FasNSeal AL29-4C Stainless Steel Special Gas Vent. Ensure the lower gasket of the universal appliance

adapter is in place and properly positioned prior to installation. Ensure the venting system does not apply a

load or strain on the boiler flue outlet adapter; recommend using two elbows to create a “swing joint” to

reduce potential strain on vent piping and cemented joints. See Figure 4-3(d).

Exhaust venting must be supported to reduce strain on piping joints. Failure to follow

these instructions may result in result in damage, serious injury or death.

In Canada, the first 3 ft (915 mm) of vent piping must be readily accessible for inspection.

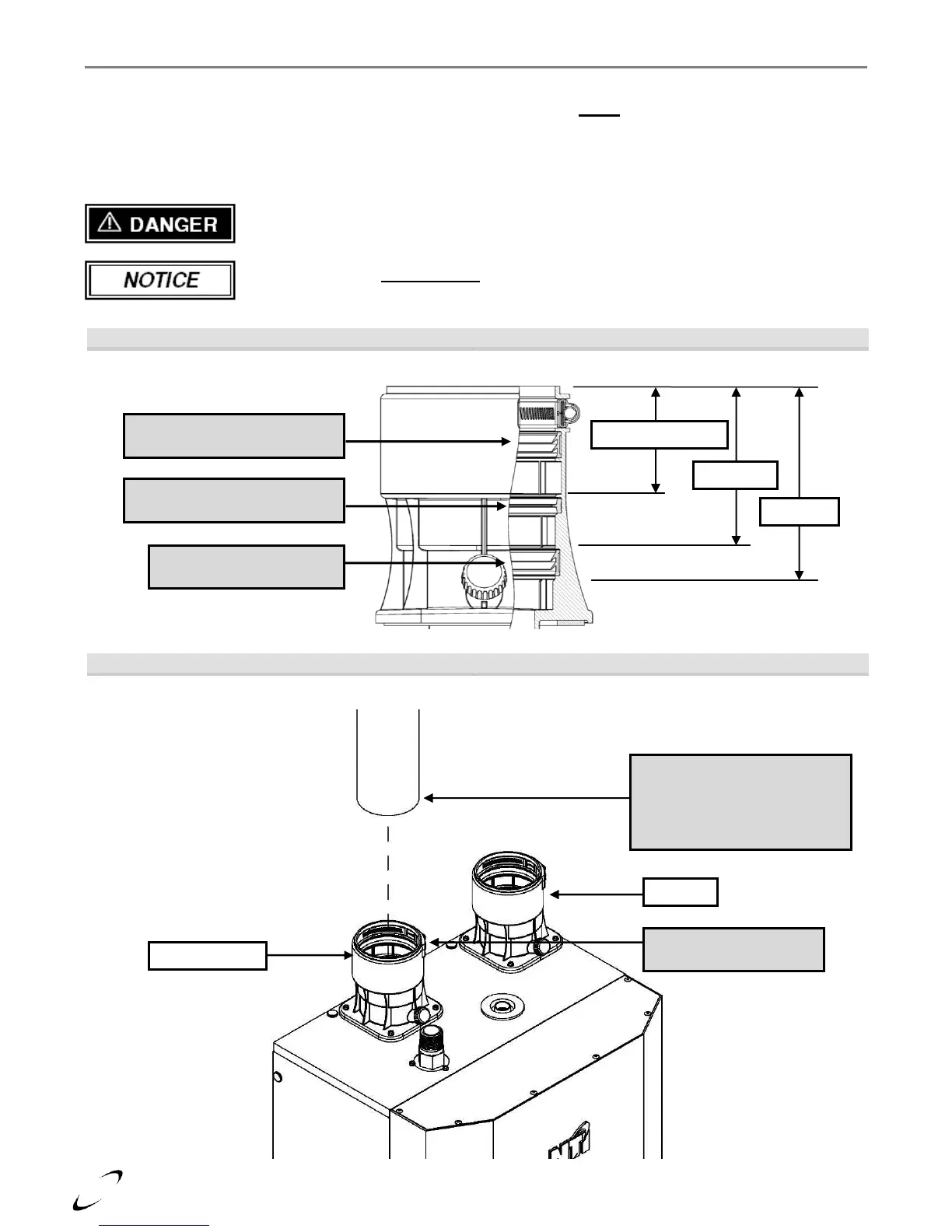

Figure 4-2 (a) Universial Exhaust-vent & Air-inlet Appliance Adapter

Gasket Identification and Pipe Insertion Depth

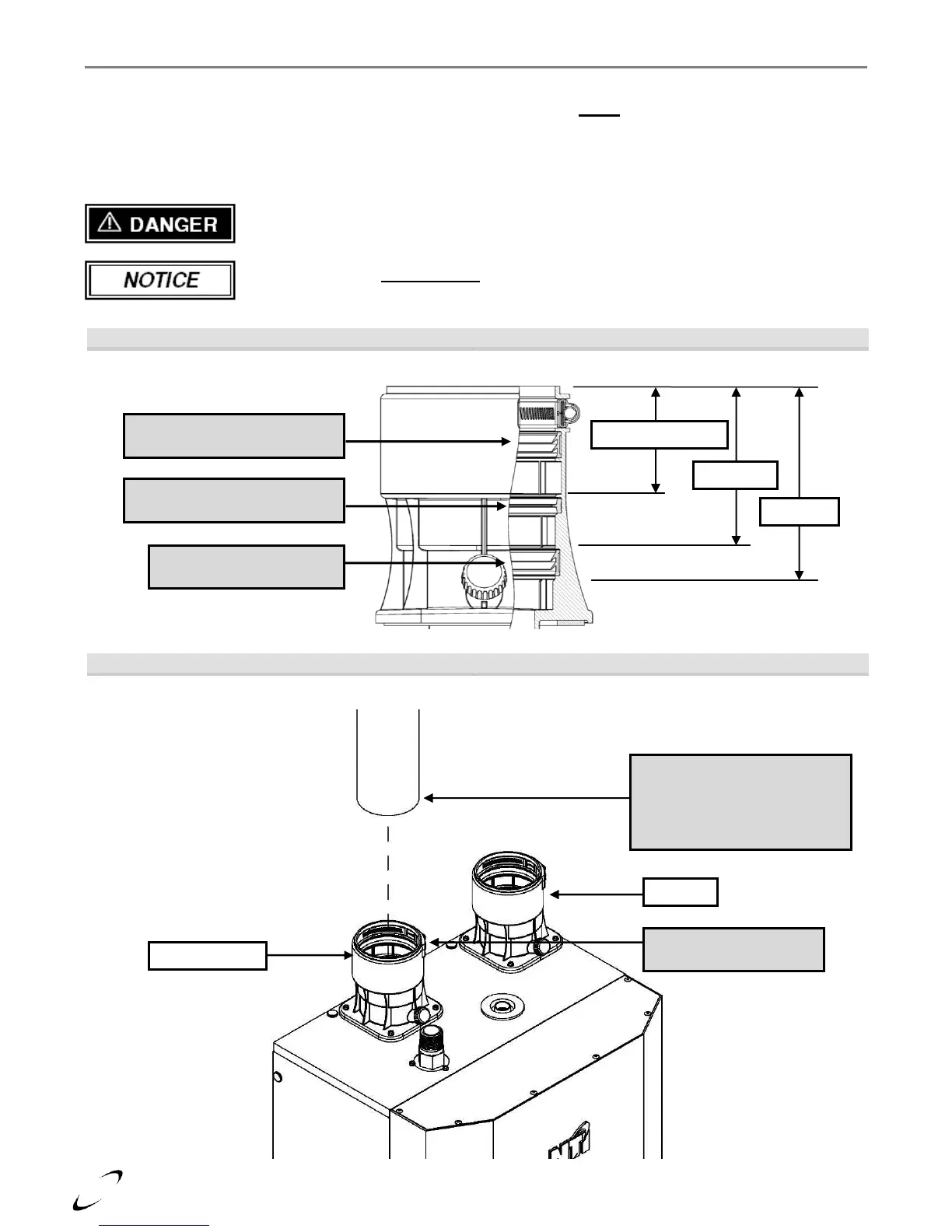

Figure 4-2 (b) Universial Exhaust-vent & Air-inlet Appliance Adapter

Proper Exhaust Vent Connection

Lower Gasket – 3” OD Seal

use with Stainless Steel

Middle Gasket – 3.14” OD Seal

use with Polypropylene

Upper Gasket – 3.5” OD Seal

use with CPVC (PVC for Air-inlet)

CPVC/PP/SS Exhaust Pipe

With 1/8” bevel to prevent

damage to gasket. When venting

with PVC, use 5” long CPVC

Transition Pipe (factory supplied)

Tighten Gear Clamp after

fulling inserting piping

Loading...

Loading...