2

15. 02. 22. Document Number 672040

Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA | nuaire.co.uk

BPS H-CO

Installation Manual

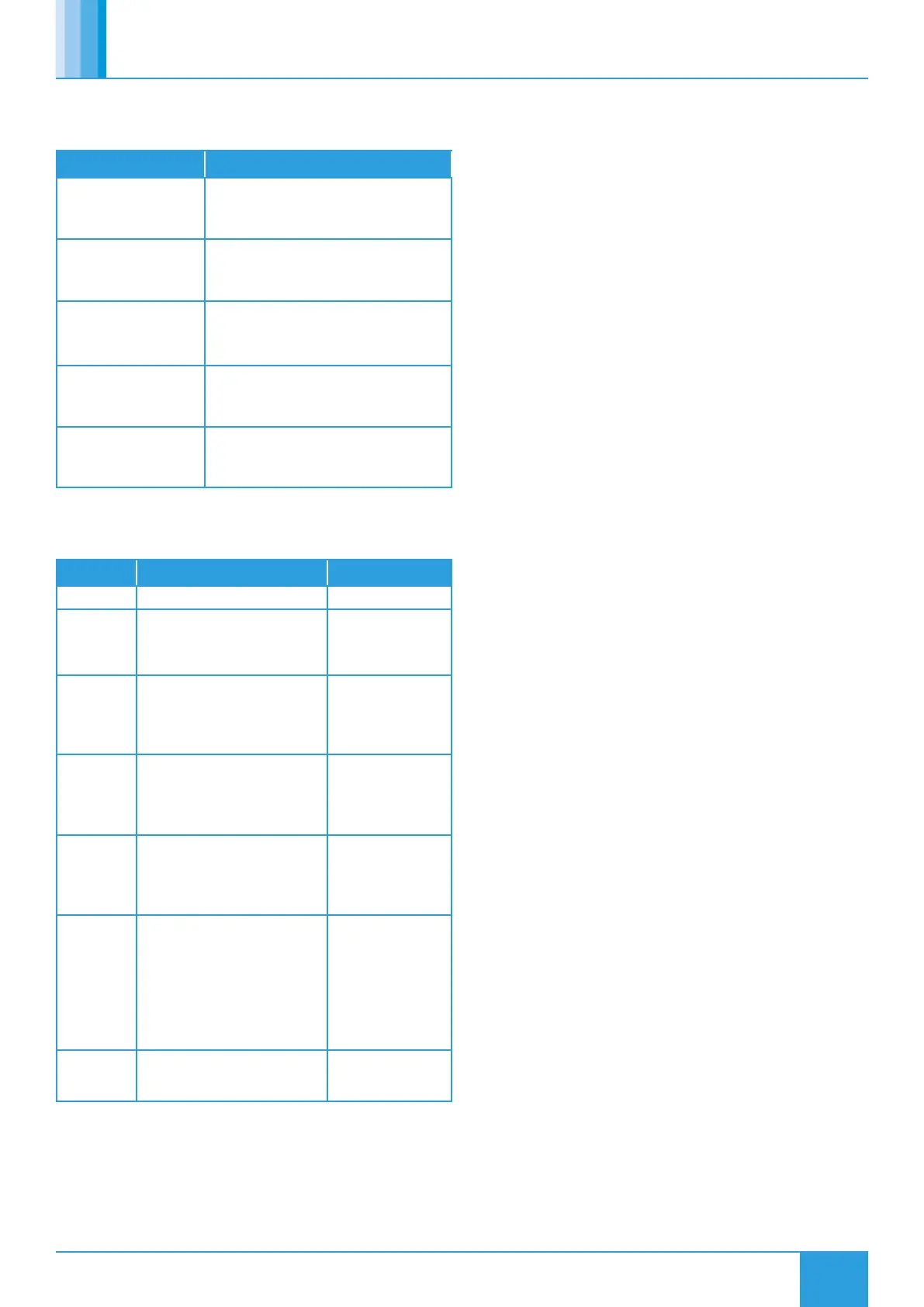

1.4 Multiple Sensors

Where multiple sensors are connected the following options are

available.

State Description

Temp Sensor Operation Room module average (Default)

Return Air only

Room Module & Return Air Average

Setpoint Operation Last Value Changed (Default)

Software Setpoint Only

Last Value Changed With Timeout

Humidity Sensor Operation Average (Default)

Max

Ignore

CO2 Sensor Operation Average (Default)

Max

Ignore

Pressure Sensor Operation Average (Default)

Max

Ignore

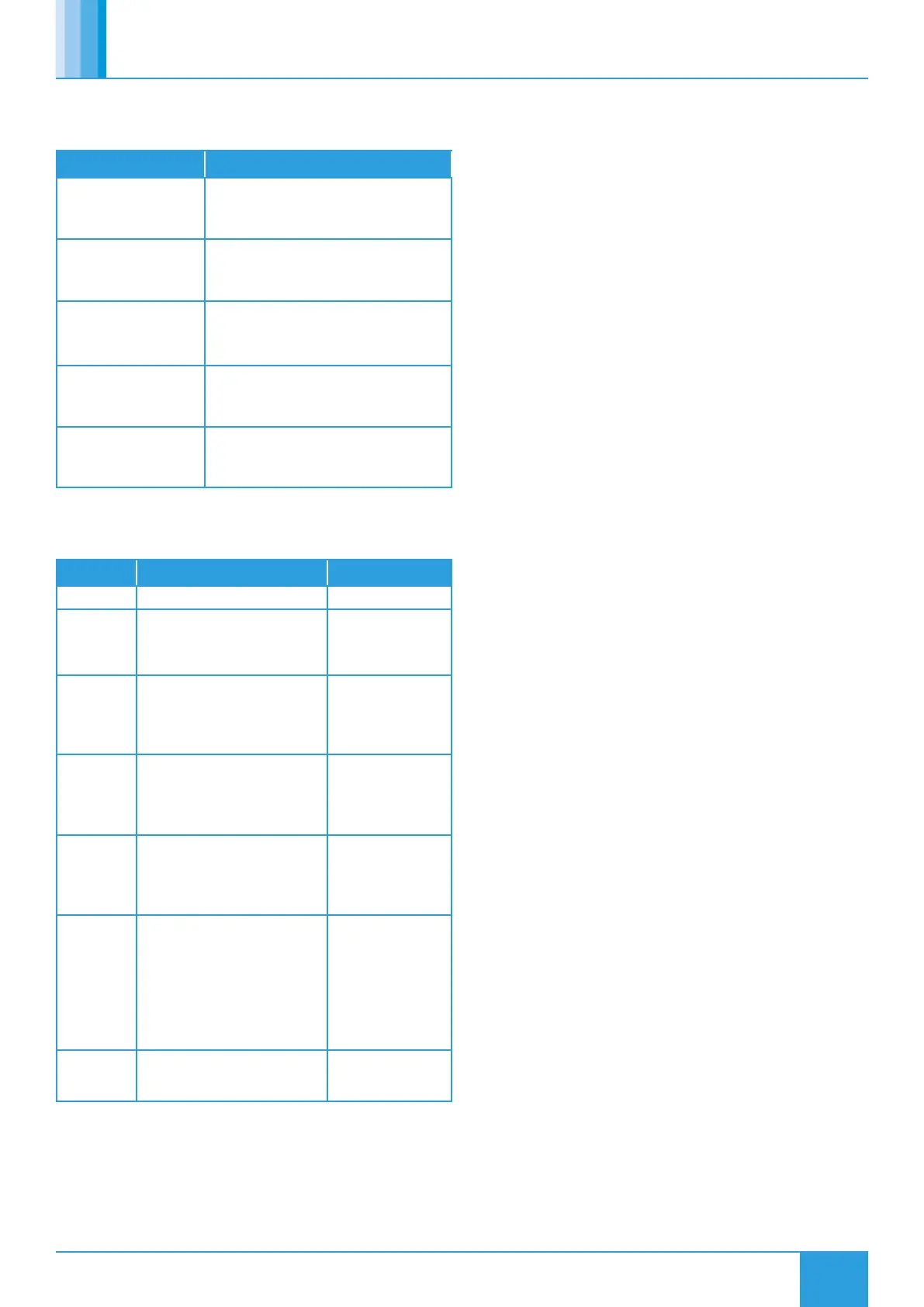

1.5 Auxiliary Inputs 16 & 17 (0-10V Inputs)

The function of IN16 & IN17 can be set by the network inputs IN16

Function & IN17 Function. The available options are as follows.

Function Description Available Ranges

None The signal is ignored N/A

Fan Speed

Control

A 0-10V input is used as a fan speed

demand.

0V = Min Speed

10V = Max Speed

N/A

EGG

(Ecosmart

Gateway

Gadget)

0-10V from the EGG PCB is controls

used as a fan speed demand. The

optional EGG PCB can be used for

backwards compatibility with some

Ecosmart Classic sensors.

N/A

0-10V

CO2 Sensor

0-10V is scaled as defined by the

network input

“CO2 0-10V Output Range”

0-2,000ppm

0-4,000ppm

0-5,000ppm

0-10,000ppm

0-20,000ppm

0-10V

Temperature

Sensor

0-10V is scaled as defined by the

network input

“Temperature Sensor 0-10V Output

Range”

0 - 40°C

0 - 50°C

0 - 80°C

0 - 90°C

0 - 100°C

0-10V

Pressure

Sensor

0-10V is scaled as defined by the

network input

“Pressure Sensor”

0 - 25 Pa

0 - 50 Pa

0 - 100 Pa

0 - 300 Pa

0 - 500 Pa

0 - 1000 Pa

0 - 1600 Pa

0 - 2500 Pa

0 - 3000 Pa

0-10V

Humidity

Sensor

0-10V is scaled to 0-100%

humidity

0 - 100% only

1.6 Fan Speed Control Input

Once assigned to either input 16 or 17, the 0-10V input is scaled to

0-100% fan speed demand.

1.7 CO

Control

When a CO2 sensor is assigned to the system and an enable signal

is received, ventilation will increase fans speeds to reduce CO2

concentration. The target CO2 sensor setpoint can be changed as

one of the commissioning setpoints. Room Module CO2 sensors are

detected automatically. 0-10V CO2 sensors need to be assigned to

input 16 or 17.

1.8 Humidity Control

When a humidity sensor is assigned to the system and an enable signals

received, ventilation will increase fans speed to reduce humidity. The

target humidity setpoint can be changed as one of the commissioning

setpoints. Room Module humidity sensors are detected automatically.

0-10V humidity sensors need to be assigned to input 16 or 17.

1.9 Constant Pressure Control

An extract air pressure sensor is fitted to IN16 standard. IN16 is

disabled by default but constant pressure control can be enabled by

setting IN16 function to 0-10v pressure sensor.

When enabled, the unit will increase the fans speeds as required until

the pressure differential between the extract air and atmosphere

reaches the constant pressure setpoint.

The target pressure setpoint can be changed as one of the

commissioning setpoints. Room Module pressure sensors are not

available.

1.10 Dirty Filter Switch

Filter differential pressure switches are fitted as standard. These

monitor the Extract filter, Supply filters. These are connected into input

IN9 & IN10 and will be open circuit on overpressure. The adjustable

range is 0.5 to 4mbar and is set by the default to 2mbar.

1.11 Configurable Mode (Via Switched Live 2)

The switched live 2 input is a configurable input that can be set to

perform a number of functions. The function is set via the network

input Configurable Mode SL2.

These functions will include the following:

•Fan Boost (Default Setting) - This enables Fan Boost Mode

•Heat Boost - The heater function will be enabled. Fan speeds will

be increased where necessary to keep supply temp at the heater

boost setpoint (Default 35°C).

•Extract Setback - When this mode is selected and SL2 is active,

the unit will force the extract fan to run at Extract Setback Speed

(Commissionable setpoint), regardless of all other demands.

Supply fan will operate at the normal speed. If increased demand

is required (e.g. via CO2 or 0-10v IN16/17 some other input) the

supply fan speed will increase but the extract fan speed will not.

This mode can be used when the unit is used in conjunction with a

separate air system.

1.11.1 Fan Boost

When the control receives a boost signal, from either the network input

“Boost” or “Configurable SL2” configured to boost, the fans will run at

their individual boost speeds. Once the signal is removed the fans will

run on for a time defined by the boost run-on setpoint. Any demand in

excess of the boost speed will be ignored (apart from 3 speed override

and purge schedule).

1.11.2 Heat Boost

When the control receives a heat boost signal, from either the network

input “Heat Boost” or “Configurable SL2” configured to “heat boost”,

the heater output will increase to 100%. The fan speed will be increased

as required to reach the heat boost setpoint.

Loading...

Loading...