PREPARE THE HOOD

(NON-DUCTED HOODS ONLY)

Note: The following materials must be purchased separately for non-ducted recircu-

lation installations.

Non - Ducted Recirculation Kit, Model RRK51.

5" diameter expandable / flexible aluminum duct.

1/16" diameter twist drill.

_IL CAUTION: Do not use plastic or rigid metal ducting.

1. Determine the length of the compressed flexible aluminum ducting using the

following formula:

34" MINUS

Distance above PLUS 12" if ceiling = Length of compressed

cook top. See Page height is 9- flexible aluminum

9, height restrictions feet. (or 24" If ductwork.

table, ceiling height

is 10 feet)

Worksheet: 34" -

(for 9' or 10' ceiling only) =

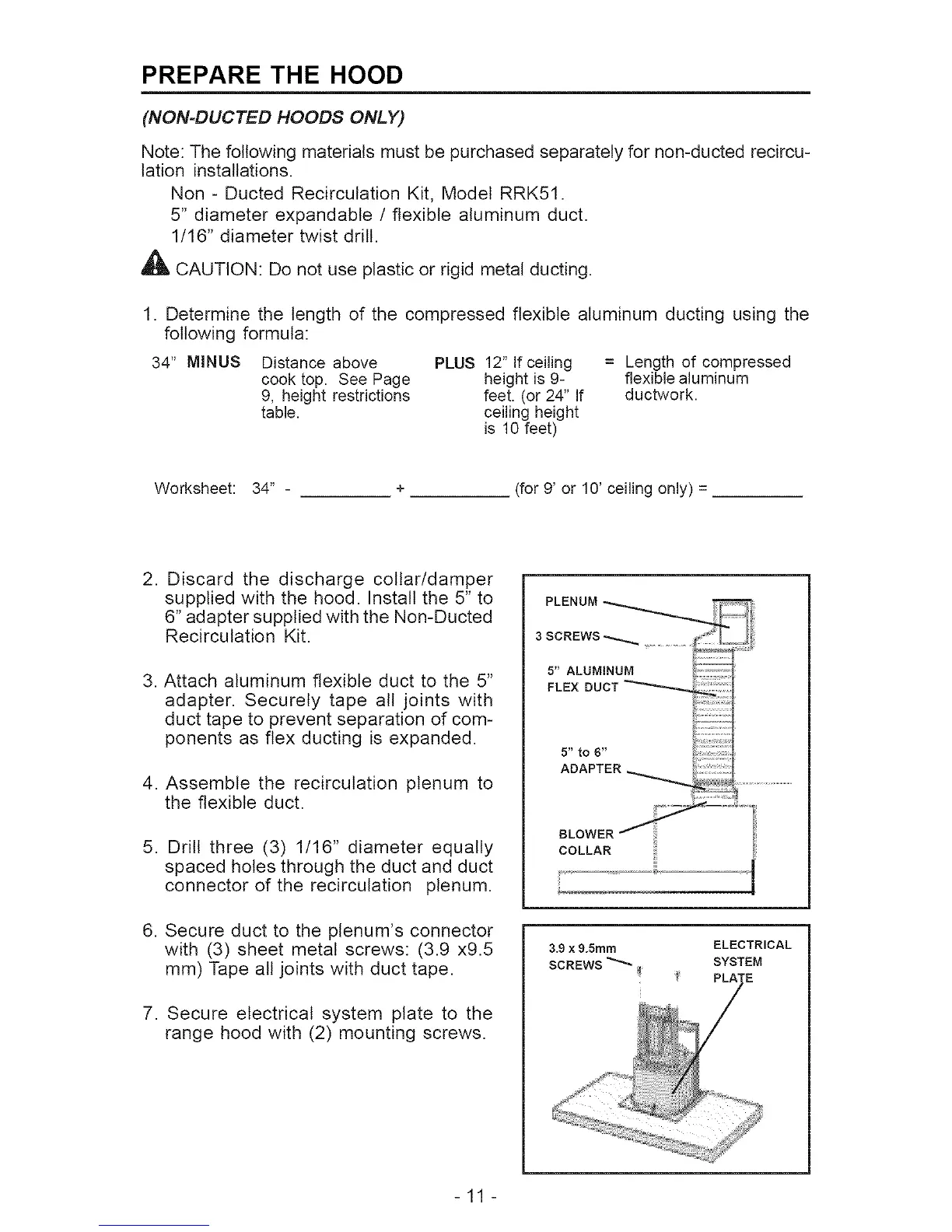

2. Discard the discharge collar/damper

supplied with the hood. Install the 5" to

6" adapter supplied with the Non-Ducted

Recirculation Kit.

3. Attach aluminum flexible duct to the 5"

adapter. Securely tape all joints with

duct tape to prevent separation of com-

ponents as flex ducting is expanded,

4. Assemble the recirculation plenum to

the flexible duct.

5. Drill three (3) 1/16" diameter equally

spaced holes through the duct and duct

connector of the recirculation plenum.

6. Secure duct to the plenum's connector

with (3) sheet metal screws: (3.9 x9.5

mm) Tape all joints with duct tape.

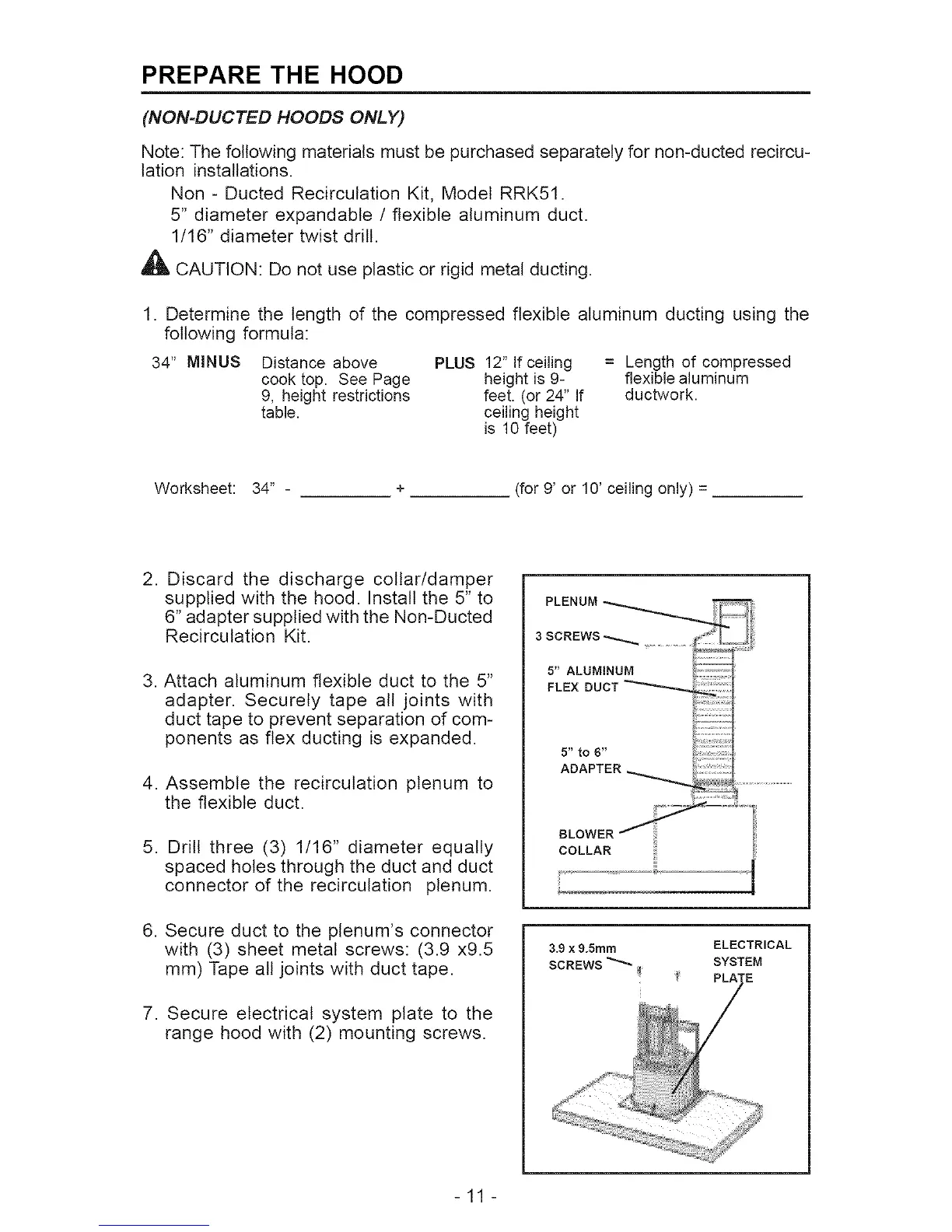

7. Secure electrical system plate to the

range hood with (2) mounting screws.

PLENUM -._

3 SCREWS

5" ALUMINUM

FLEX DUCT

ADAPTERS"*o

3.9 x 9.5rnm ELECTRICAL

SCREWS _ SYSTEM

-11 -

Loading...

Loading...