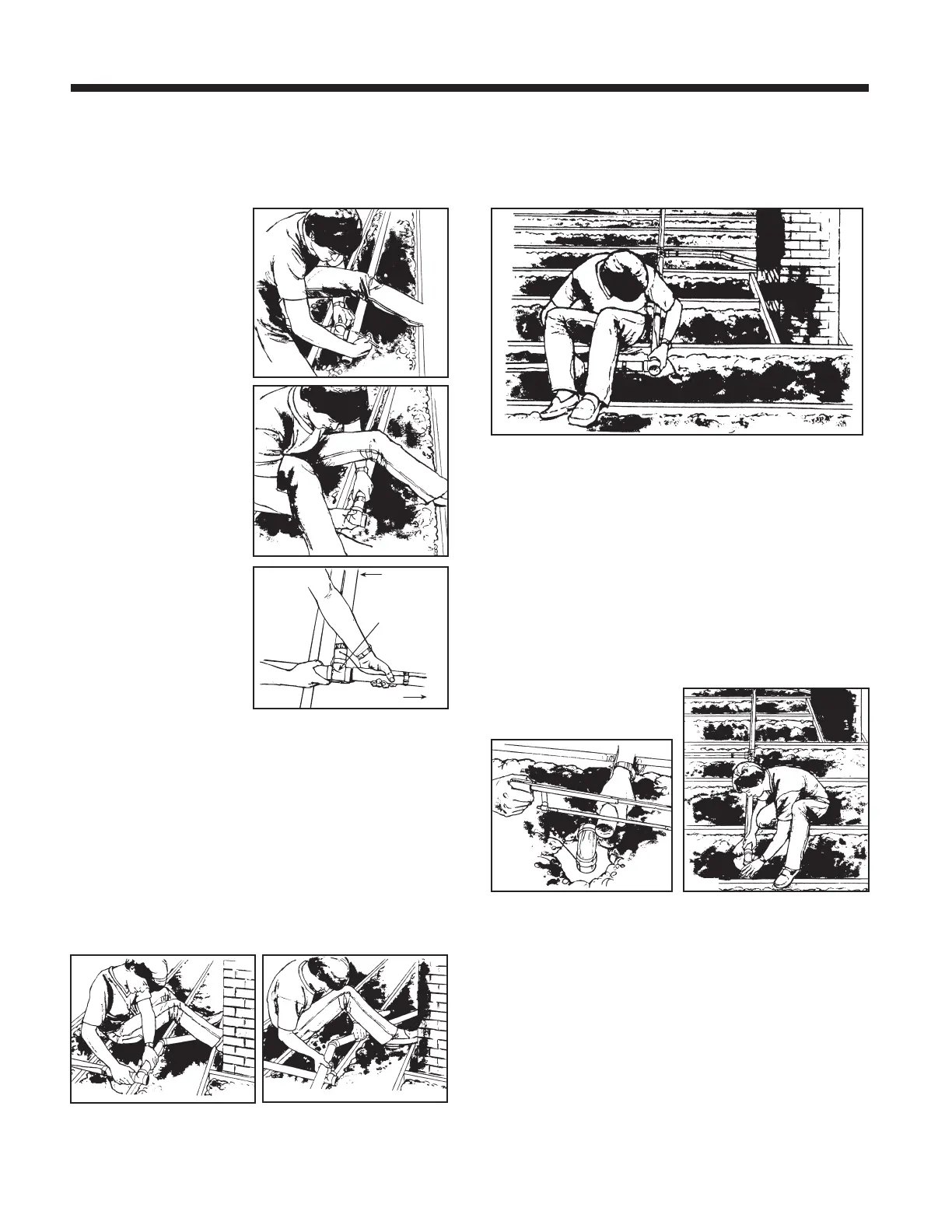

Connecting a Branch Line

A branch line connects

the inlet line to the trunk

line. Follow the methods

previously described for

aligning, marking and

cutting the inlet tubing.

Attach a 90° elbow and

run tubing from the inlet

line to the trunk line.

To align and measure the

branch line, attach a 90°

tee fitting to the trunk

line. Make sure the tee

connects with the air flow

going toward the power

unit. Align, measure, and

mark the branch line for

inserting it into the tee

fitting. Then, cut the

branch line to length and

insert it into the tee.

Check to make sure the

cut is straight and even.

Connect the next section

of tubing to the out-take

side of the tee fitting.

Continue the trunk line

until you come to another

branch line junction point.

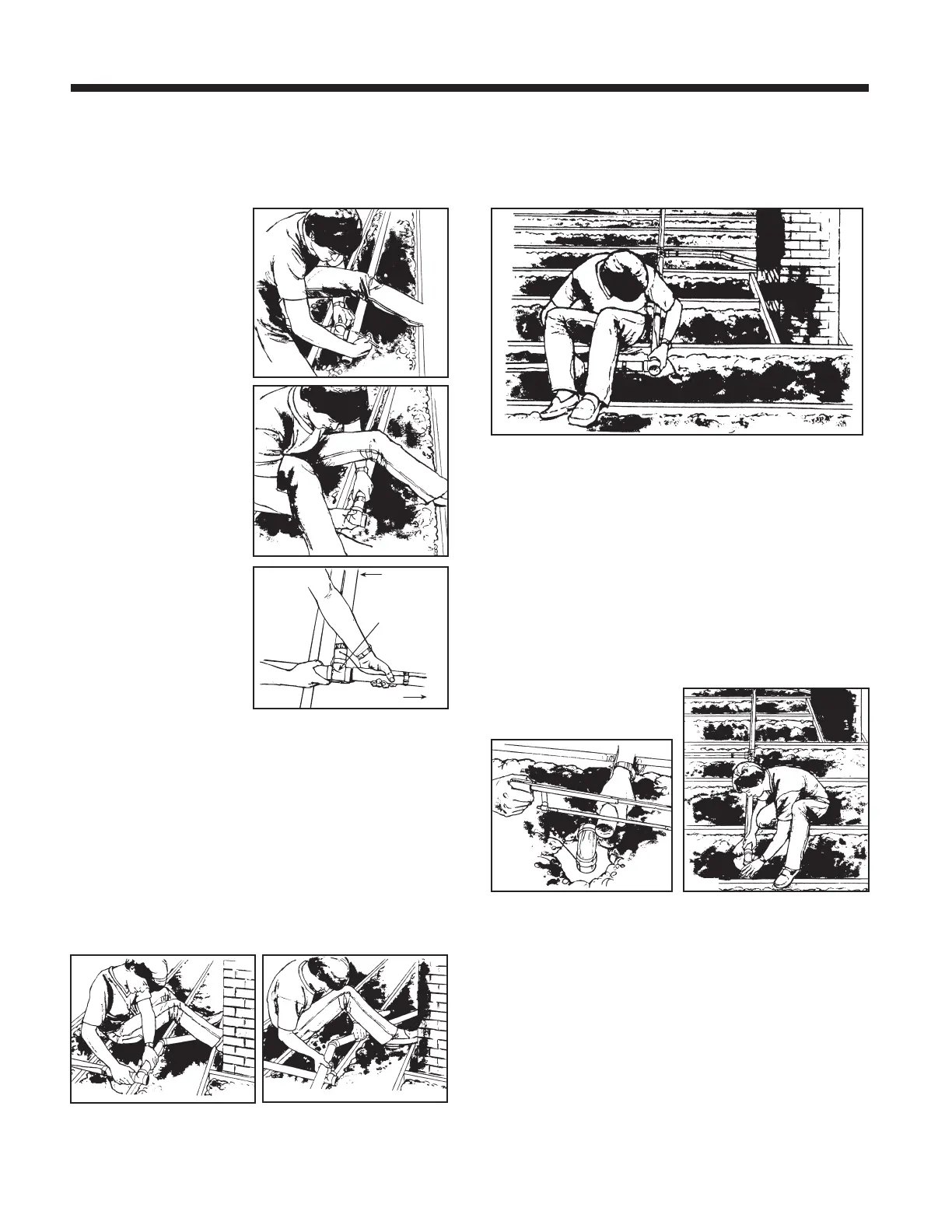

Circumventing an Obstacle

Wherever possible the branch lines should connect to the

trunk line in straight paths. The fewer turns in a tubing system,

the more efficient air flow. Accordingly, you should locate the

inlets to avoid zig-zags in the branch lines. But, sometimes,

when you just can’t avoid an obstacle, you are required to

construct the tubing around it.

In the example illustrated here, you might run the branch line

at an angle to avoid a chimney. Then, once the branch line

has run past the chimney, you can use a 45° elbow to turn the

branch line back perpendicular to the trunk line. Again, the

branch line and the trunk line connect with a 90° tee.

You can also use a piece of flexible tubing to run a branch line

around an obstacle. See “Using Flexible Tubing,” on page 17.

Completing the Trunk Line

Continue to run the trunk line toward the power unit,

connecting all branch lines as you go along. Again, make sure

you connect all fittings with the air flow toward the power unit.

Bring the trunk line to the access hole you have drilled for the

power unit’s intake tube. Place a 90° elbow over the hole and

cut the trunk line to fit into this final elbow. Allow 5/8” (16 mm)

of tubing to fit into the elbow’s collar. Connect the elbow to the

trunk line so that it aligns over the intake access hole. You

will make the intake tube

connection itself after you

have installed the power unit.

When you are satisfied that all fittings and tubing are aligned

for maximum air flow, make sure that all your cuts are square

and that all joints are tight. Then, prepare the tubing and

cement the joints as described in “Working With Plastic

Tubing,” page 4.

Connecting the Low-Voltage Wiring

Ideally, you will run the wiring and make all the wiring

connections after you have completed the tubing system.

Of course, the inlet wiring must be run at the time the inlet

tubing is threaded through the walls.

Loading...

Loading...