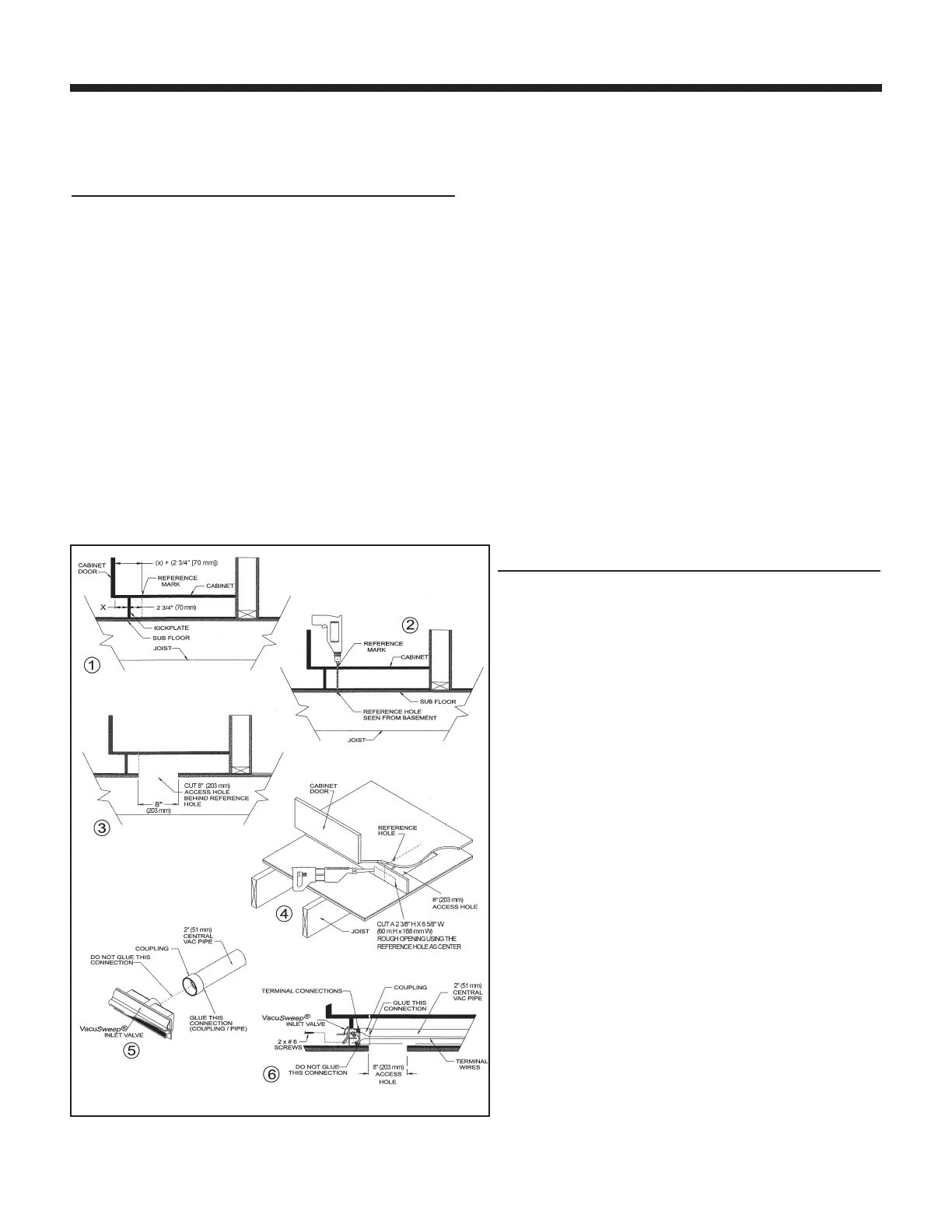

CONNECTION FROM BEHIND

Refer to Figure 25.

1. Turn the power to the vacuum unit OFF. Choose a location

under the cabinet for the VacuSweep Inlet Valve so that it

can be connected to the central vacuum tube. Measure

distance (X) between the kickplate face and the inside

edge of the cabinet. Then, add 2¾” (70 mm) to the

measured distance. Refer to Figure 25-1. Measure out the

new distance (X + 2¾” [70 mm]) from the cabinet door, to

the reference mark.

2. Drill a small reference hole straight down through to the

basement. Refer to Figure 25-2. Locate the reference hole

in the basement and verify that there are no obstructions.

3. Using a reciprocating saw, cut an access hole in the floor

under the cabinet and approximately 8” (203 mm) behind

the location of the VacuSweep Inlet Valve reference hole

so that the VacuSweep Inlet Valve can be connected to

vacuum tube by reaching through the access hole. Refer to

Figure 25-3.

4. Using the reference hole as a center, cut a 2⅜” H x 6⅝” W

(60 mm H x 168 mm W) rough opening in the kickplate

face. Refer to Figure 25-4.

5. Insert a coupling (part no. V127) onto the rear of the housing.

DO NOT glue this connection (Designed for friction fit).

Refer to Figure 25-5. Make the terminal connections to the

VacuSweep Inlet Valve by sliding the low-voltage wire into

wire clips. Turn the power to the vacuum unit ON to test the

connection. After successful completion of the test, turn

power to the vacuum unit OFF. Insert the VacuSweep Inlet

Valve into the cabinet base and tube.

6. With the door in an open position, secure the VacuSweep

Inlet Valve to the cabinet base using no. 6 screws.

Refer to Figure 25-6. Ensure that the spring on the electrical

connector has 1/8” (3 mm) clearance to rough opening.

From the basement reach through the access hole and

glue a section of 2” (51 mm) central vacuum tube to the

coupling. Continue with remainder of central vacuum

connections. When the vacuum system is complete, turn

the power to the vacuum unit ON.

CONNECTION IN A WALL

Refer to Figure 26 on page 14.

1. Turn the power to the vacuum unit OFF. Remove the

baseboard and locate studs in the wall where VacuSweep

Inlet Valve will be installed. Locate a position where the

inlet will be clear of vertical studs and have free access

either up or down dependent on location of central vacuum

connection to the rest of the system. Refer to Figure 26-1.

2. Holding the drill at a 45º angle and as close to the wall as

possible, between located studs, drill a small reference

hole through the floor and subfloor. Locate this reference

hole from beneath and measure over approximately

1⅞” (48 mm) to center of base plate of wall. Ensure you

have 1½" (38 mm) clearance from any obstacles if

connecting from below. Refer to Figure 26-2.

3. If installation is from below use a 2½” (64 mm) diameter hole

saw to remove wood floor and base plate, sufficient to

locate VacuSweep Inlet Valve centered over the reference

hole. Refer to Figure 26-3.

4. Using the reference hole as a center, cut a 2⅜” H x 6⅝” W

(60 mm H x 168 mm W) rough opening in the wall and

baseboard. Refer to Figure 26-4.

page 13

Loading...

Loading...