32

GB

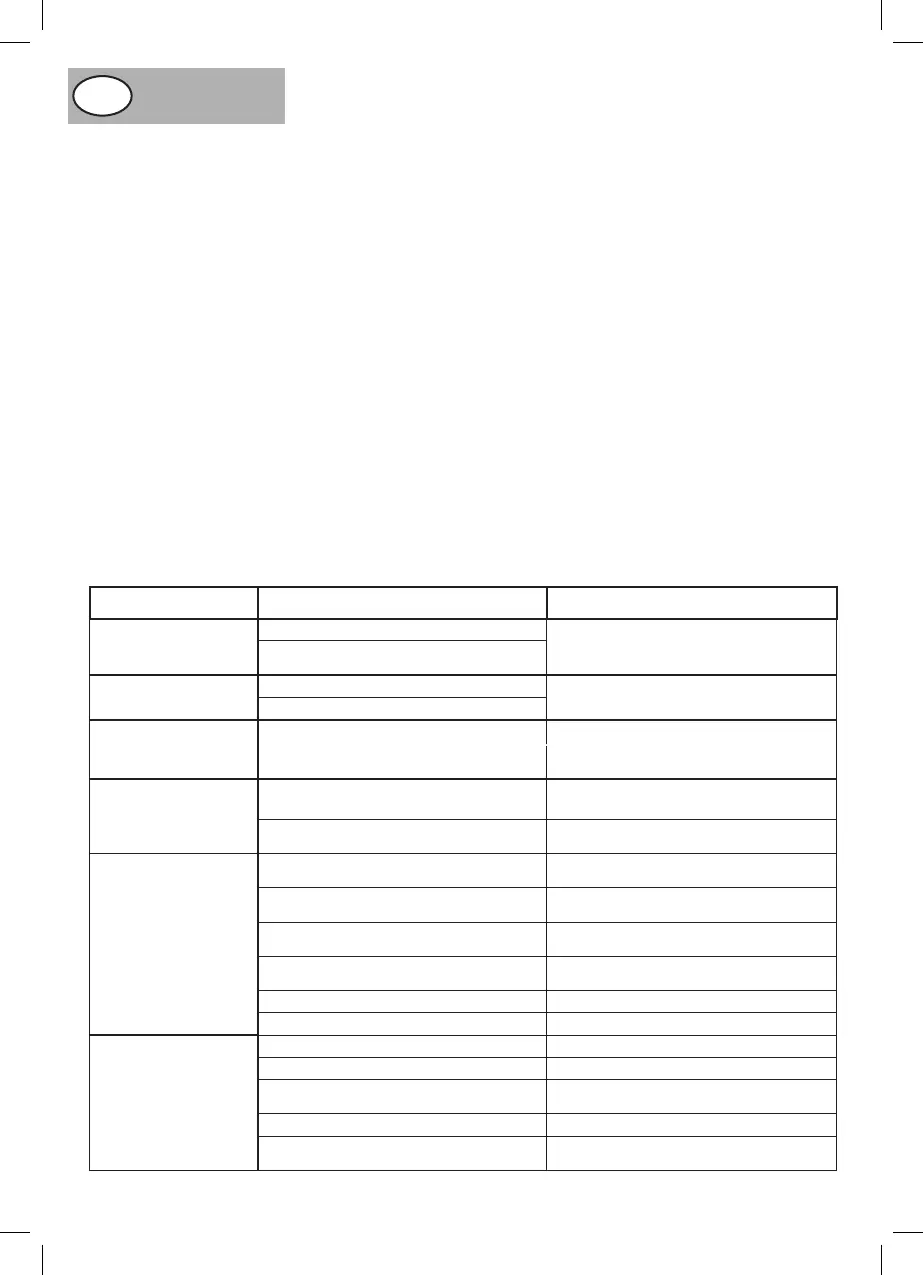

PROBLEM POSSIBLE CAUSE REMEDY

The saw will not start

Saw is not plugged in and switched on Plug in and switch on

Fuseblown,circuitbreakeror(RCD)has

tripped

Replacefuse,re-setcircuitbreakeror(RCD).

Does not make accurate

45°or90°ripcuts

Tilt stops not adjusted correctly

Check the blade using a set square and adjust

thestopcorrectly.Adjustthepointerto0°

Tilt pointer not set at accurately

The material pinches the

blade when ripping

Ripfenceisnotalignedwiththeblade. Check alignment of blade and adjust

Warpedmaterial,theedgeagainstthe

ripfenceisnotstraight.

ifrequired.Trueupunevenedge.

Select another piece of material

The material binds on

therivingknife.

The riving knife is not correctly aligned

with the blade

Check the alignment of the riving

knifeandadjustifrequired.

The blade set is narrower than the riving

knife.

Selectanotherbladeorrivingknife.

The material is kicked

backfromtheblade.

The rip fence is out of alignment

Check the alignment of the rip fence

andadjustifrequired.

The riving knife is not aligned with the blade or

notfitted.

Check the alignment of the riving knife and

adjust/fitifrequired.

Feeding the material without using the rip

fence.

Installtheripfence.

Releasingthematerialbeforethecutis

completed

Feed the material all the way through before

releasing the material

Adullblade Replacetheblade.

The mitre gauge locking knob is not tightened Secure the locking knob

The saw makes an

unsatisfactory cut

Dull blade Mountthebladethecorrectwayround.

Blade mounted backwards Fissarelalamanelsensocorretto.

Gum or pitch build up on the blade

Removethebladeandcleanwith

suitablecleanerandsteelwool.

Incorrect blade for the operation Usethecorrectblade.

Gum or pitch build up on the table

causing erratic feed

Clean the table with suitable cleaner

andsteelwool.

FAULT FINDING

andoperatingproperly.Checkthatthebladeissetto90°andat

itslowestposition.Ensurethatthetableisclearofanytoolsor

othermaterials.Ensurethatallnuts,boltsandotherfastenings

aresecure.Ifthemachinemakesanyunusualnoiseorvibrates

excessively, STOP the machine immediately and investigate the

causeandrectify.IfthecausecannotbeidentifiedNONOTuse

themachineandcontactyournearestservicecentre.

LUBRICATION (PIC.40)

Before lubricating, remove the bottom safety cover by removing

thecrossheadpanscrews.(Pic.40) Lubricate the blade tilting

operating screw and both pairs of locking and adjustment nuts

and the blade elevating threaded rod once a month using a light

machineoilorothersimilarlubricant.

MAINTENANCE

Do not make any adjustment while the motor is in motion,

Alwaysmakesurethemachinesplughasbeenremovedfrom

the mains power source before changing brushes, lubricating

orwhendoinganyworkormaintenanceonthemachine.After

each use, check your machine for damage or broken parts and

keep it in top working condition by repairing or replacing parts

immediately.Cleanoutaccumulateddust.Duringusethecarbon

brushes will wear down, this will be indicated by a possible loss

of power and excessive sparking seen through the ventilation

slots.Whenthebrusheshaveworndowntoapproximately4-

5mmtheywillrequirereplacing.Removethetworoundcover

plates, one on either side of the motor casing (Pic.41).Remove

the worn carbon brush and replace it with the new one, and

re-fittheroundcoverplate,Repeatthisoperationfortheother

carbonbrush.Replacetherectangularcoverplateandsecure

withthescrew.NOTE:Carbonbrushesmustalwaysbechanged

asapair.

WARNING

To assure safety and reliability, all repairs with the exception

of externally accessible brushes should be performed by

AUTHORISED SERVICE CENTRE or any other authorised

servicecentreororganisations.

NOTE: In all cases where electrical problems occur consult a

qualifiedelectrician.Isolatethemachineandunplugfromwall

socket before attempting to work on the machine even if the

problemseemsminor.

Loading...

Loading...