12x7-9 13x6-8

Use a tank designed for gasoline. (Tanks designed

for glow fuel use a rubber cap which is deteriorated

by gasoline.)

A 160cc tank will provide 12 to 13 minutes flight.(With

full throttle, it will provide 8 to 10 minutes flight.)

Install a commercially available gasoline fuel filter

between fuel tank and carburetor. (Clean the filter

from time to time.)

FUEL TANK & LINES

CARBURETOR PARTS NAME

PROPELLER

The choice of propeller depends on the design and

weight of the aircraft and on the type of flying in which you

will be engaged. Determine the best size and type after

practical experimentation. As s starting point, refer to the

props listed in the table shown below. Slightly larger, or

even slightly smaller props than those shown in the table

may be used, but remember that propeller noise will

increase if blade tip velocity is raised due to high rpm or if

a larger diameter/lower pitch prop is used. Be well aware

that the propeller rotating arc will increase when using a

larger propeller with this engine. Carry out the needle

adjustments only after stopping the engine. Do not allow

your face or hands to come close to the rotating prop.

Type

Size (DxP)

Sport/Acro/Scale

Warning:

Make sure that the propeller is well balanced.

An unbalanced propeller and/or spinner can cause

serious vibration which may weaken parts of the

airframe or affect the safety of the radio-control system.

Do not use any propeller which has become split,

cracked or nicked even very slightly, or received

strong impact even if no apparent damage is visible.

Since the GGT10 is intended to be started with an

electric starter, the addition of a spinner assembly for

centering the starter sleeve is desirable.

Special propeller locknut sets are available for use

with spinners. Use a good quality well balanced

spinner, enclosing the propeller boss.

Make sure that it is of precision-made and sturdy

construction so that the spinner shell cannot loosen

when the starter is used.

Make sure the spinner notches do not interfere the

propeller. If they do, cut the notches to clear.

MIXING OF OIL

Use regular gasoline. (No need to use high octane

gasoline.)

Alcohol based glow fuel cannot be used in this

engine. Not only will the engine not work properly

but the internal carburetor plastic parts will be

damaged.

Use high quality commercially available 2 stroke

engine oil.

Follow the oil manufacturer’s recommendations

concerning the mixture ratio of gasoline and oil.

If there is no recommendation, mix with a 25~30:1.

We have checked the following oils with the

mixture of 50:1.

KLOTZ ModeLube®

AMSOIL Saber

Zenoah Genuine FC Class

Concerning the mixture ratio for running-in, follow

the instructions in the RUNNING-IN section.

Regulator

It is recommended to seal the fitting faces of engine

exhaust and silencer with liquid gasket. Gasket at the

joint part of the silencer will lose its sealing effect in a

long time running. In this case, replace the gasket or

apply liquid gasket to the joint.

Use fuel line keepers of stainless wire, etc. at the end

of the tubing to prevent the tubing from coming off.

This engine does not require a muffler pressurized

fuel system but be sure to provide an air vent.

Be sure to use a gasoline

resistant fuel tank cap.

Be sure to equip

air vent pipe.

Be sure to use fuel line keepers of

stainless wire, etc. to prevent tubing

from coming off.

Be sure to replace tubing

inside periodically.

To the fuel

pump inlet

tubing for

re-fuelling

Be sure to install an in-line fuel filter between the

tank and carburetor to prevent foreign matter in the

tank from entering the carburetor. Clean the filter

periodically.

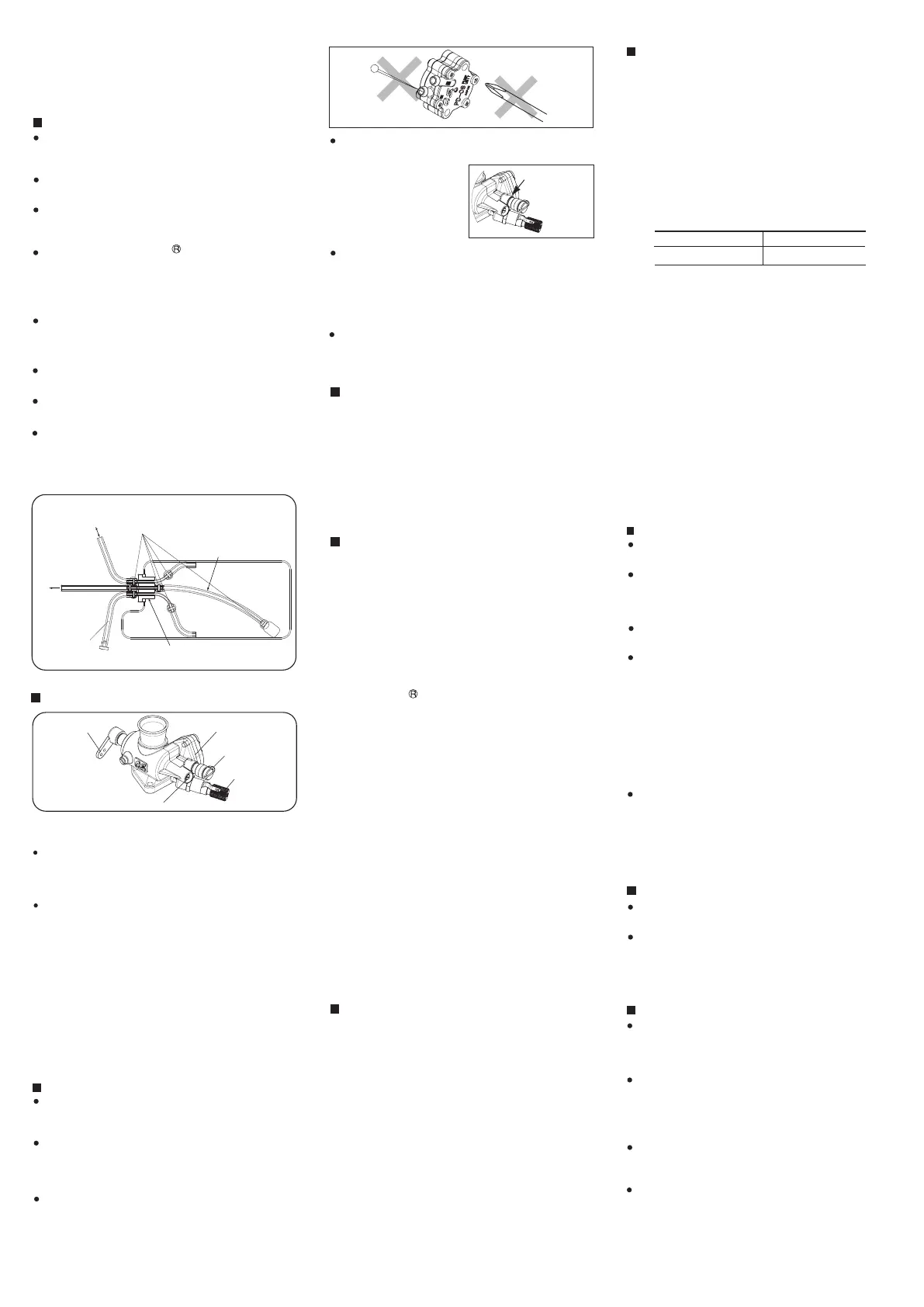

Needle Valve

Mixture Control Valve

Throttle Lever

Fuel Inlet

NEVER disassemble the fuel pump or pressure

regulator. Their original performance may not be

restored after reassembly.

DO NOT allow foreign matter to enter the fuel

system. Dirt inside the pump or regulator, no matter

how small, may obstruct the flow of fuel and prevent

these components from working properly.

CARE OF FUEL PUMP & REGULATOR

DO NOT obstruct the small rectangular hole at the

bottom of the regulator, nor the regulator will not

function correctly.

NEVER insert anything into the inlet or outlet nipples

in an attempt to clear a suspected obstruction.

ALWAYS use fuel filters. Keep the fuel tank

scrupulously clean and filter all fuel as it enters the

tank (e.g.via an O.S.'Super-Filter' Code No.72403050)

and use a good quality in-line filter between the tank

and pump. Remember to inspect filter screens at

regular intervals and rinse clean as necessary.

Rectangular

hole

NEVER use kerosene, thinner or any organic solvent

for cleansing the pump. Rubber parts will be ruined

by these materials. Use only alcohol (methanol) or

gasoline.

THROTTLE LINKAGE

Before connecting the throttle to its servo, make sure

that the throttle arm and linkage safely clear any

adjacent part of the airframe structure, etc., as the

throttle is opened and closed. Connect the linkage so

that the throttle is fully closed when the transmitter

throttle stick and its trim lever are at their lowest

settings and fully open when the throttle stick is in its

fully-open position. Carefully align the appropriate holes

in the throttle arm and servo horn so that they move

symmetrically and smoothly through their full travel.

For plumbing use TYGON F-4040A (Yellow color)

or strong nitrile rubber of more than 2.4-3.2mm ID

and 4.8-6.4mm OD. Replace tubing periodically as it

becomes hardened. (Replace tubing inside the fuel

tank every six months.)

The Needle-Valve

For adjusting the mixture strength when the throttle is

fully open Needle-valve adjustment effect the mixture

strength at round mid speed.

The Mixture Control Valve

For adjusting the mixture strength at part-throttle and

idle speed, to obtain steady idling and smooth

acceleration to mid speed.

Two adjustable controls are provided on this

carburetor.

Please note with this carburetor, needle-valve

adjustment does not effect the mixture control valve

adjustment but the mixture control valve adjustment

effects the needle-valve adjustment. Therefore, it is

required to adjust also the needle-valve when the

mixture control valve is adjusted. Mixture control valve

is pre-set at the near-best position when the engine

leaves the factory. Therefore, it is not necessary to

adjust the mixture control valve until running-in is

completed.

Use a fuel with increased oil content and set the

needle a little on the rich side. Too rich a needle

setting may cause misfiring or erratic running due to

fouling of the plug.

Use a 25:1 fuel/oil mixture if the particular brand of

oil states 50:1 mix. Use a 20:1 fuel/oil mixture if the

particular brand of oil states 25:1 mix.

Set only the high speed needle 200 below maximum

rpm. The low speed needle need not be richened.

No need to carry out running-in on a bench nor with

the model fixed. Just fly the model with the above

mentioned fuel and needle setting.

A total of 10 flights (2 litters fuel) are required.

Avoid prolonged full throttle running at initial stage,

and gradually extend the full throttle running time.

RUNNING-IN

GLOWPLUG IGNITER

For the plumbing in the fuel tank, we recommend

using O.S. fluororubber tube 2 mm ID x 4 mm OD x

500 mm length (code # 28382100).

A glow plug heater for GGT10 is nothing special.

You can use a conventional glow plug igniter.

You may find the G5 glow plug filament does not

glow as bright as the conventional glow plugs.

But you can start the engine without difficulties since

the flashpoint of gasoline is lower than that of

alcohol based glow fuel.

With a gasoline engine, passages in the carburetor

are narrower than that of a glow engine, and

therefore very sensitive against foreign matter such

as dust. It is suggested to use optional accessory

Super Filter L (Code No. 72403050) when filling a

tank in the model from a container used for

transportation or storing.

FUEL TUBE BUBBLES

Heat transferred to the PD-08 pump during engine

operation may create bubbles in the fuel tubing

between the pump and carburetor. The bubbles will

prevent the engine from performing properly. Even

if the air temperature is relatively low, heat can be

transferred to the pump due to your cowling

design. If this happens, you can correct it by (1)

cutting a vent in the cowling that allows cool air to

pass through, or (2) relocating the pump inside the

firewall or outside the cowling.

HOW TO RELOCATE THE PD-08 PUMP

1. Remove the pump.

Unscrew the M3x28 fixing screws (2 pcs). Take out

the pump.

2. Remove the pulse tube.

Disconnect the short yellow pulse tube that

connects the engine cover plate to the pump.

You’ll see a pulse spacer inside the short tube.

Take it out, set it aside and do not lose it.

3. Extend the pulse tube.

Use TYGON F-4040A (yellow) or strong nitrile

rubber of at least 2.4 to 3.2mm ID and 4.8 to 6.4mm

OD. To avoid engine malfunction, the maximum

length of the tube should not exceed 150mm. You

may not need to use the pulse tube spacer if the

tube is much longer than the factory setting.

Otherwise, insert the spacer (which regulates pulse

pressure to the pump) into the tube.

Use stainless wire keepers at the end of the tubing

to prevent it from coming off. The tubing will harden

over time, so replace it periodically.

4. Attach the pump.

If you attach the pump on a frame or cowling, the

existing M3 x 28 screws might not be long enough.

You may need extra M3 screws and nuts.

You can also choose not to attach the pump in the

fuselage. In this case, wrap it with foam or sponge

so it will not move around. Also be sure to bind the

pump itself tightly with the existing screws and M3

nuts (the nuts are included as standard accessories).

If you don’t, fuel may leak from the pump.

Loading...

Loading...