Do you have a question about the O.S. engine MAX-21RG Series and is the answer not in the manual?

| Practical RPM | 2, 000 - 18, 000 RPM |

|---|---|

| Type | 2-stroke |

| Displacement | 3.5 cc |

| Fuel Type | Glow Fuel |

| Propeller Size | 9x6 |

| Glow Plug | O.S. #8 |

| Shaft Diameter | 6 mm |

Covers events involving serious, potentially fatal injury from misuse or neglect.

Covers other dangers, generally less obvious, that may cause damage or injury.

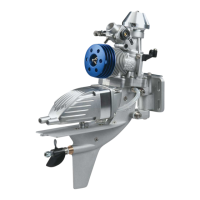

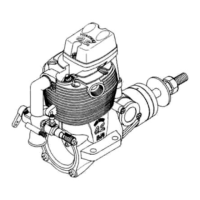

Diagram and labels of the engine's main components.

Instructions for correctly installing the glowplug into the cylinder head.

Guidance on securely mounting the engine to the vehicle chassis.

Steps for securely fitting the carburetor into the engine's intake boss.

Description of the heavy-duty wet type air cleaner for model cars.

Step-by-step guide for assembling the air cleaner components.

Instructions for attaching the air cleaner to the carburetor.

Guidelines for replacing the air filter element based on usage conditions.

Checks and procedures before the initial engine start or daily operation.

Additional safety and operational advice for the engine and air cleaner.

Important warnings and handling instructions for the recoil starter mechanism.

Information on glowplug types, function, and life extension.

Tips for extending glowplug life and signs indicating replacement is needed.

List of necessary tools and accessories for operating the engine.

Recommendations for selecting and using suitable fuel for the engine.

Information on the power source for heating the glowplug.

Description of leads used to connect the battery to the glowplug.

Recommended tool for glowplug removal and replacement.

Specification for the required tool to fill the fuel tank.

Requirements for starting the engine using an electric starter.

Specification for the heatproof silicone fuel line.

Details on adjusting needle-valve, mixture screw, and throttle stop screw.

Adjustment for mixture strength at full throttle.

Adjustment for mixture at part-throttle and idle.

Setting the minimum idling speed.

Recommendation for using a pressurized fuel system for consistent running.

Steps for properly breaking in the engine for optimal performance and life.

List of common issues to check when the engine won't start.

Procedures for fine-tuning the engine for optimal speed and response.

Detailed steps for adjusting the mixture control for optimal performance.

Importance of keeping carburetor fuel orifices clear for proper function.

Instructions for adjusting the ball link and slide valve extension.

Procedure to reset the mixture control valve to its standard position.

Checks and procedures before the initial engine start or daily operation.

Discusses fuel contaminants, filter cleaning, and after-run oil procedures.

Listing of available genuine parts and accessories for the engine.

Diagram showing the exploded view of the engine components.

List of engine parts with corresponding codes and descriptions.

Diagram showing the exploded view of the carburetor components.

List of carburetor parts with corresponding codes and descriptions.

Technical drawings of the engine with dimensions.

Key technical specifications of the engine, such as displacement and RPM.

Loading...

Loading...