- EN -

22

Addressing via DMX-RDM

RDM (Remote Device Management) is a new, open and bi-directional protocol standard for DMX-controlled devices.

The permanently transmitted DMX data flow briefly pauses (several milliseconds), and an RDM data package (mes-

sage) is sent directly to a subscriber. The subscriber evaluates the information in the data package and sends an an-

swer (semi-duplex) on the same line. Targeted polling to a subscriber via its UID (Unique ID) prevents several sub-

scribers from answering simultaneously.

The protocol makes it possible to receive status information about a unit or to change configurations on a unit. Chang-

ing the configuration means, e.g. changing the DMX address. The prerequisite for this function is a RDM-compatible

controller. Read the corresponding operating instructions

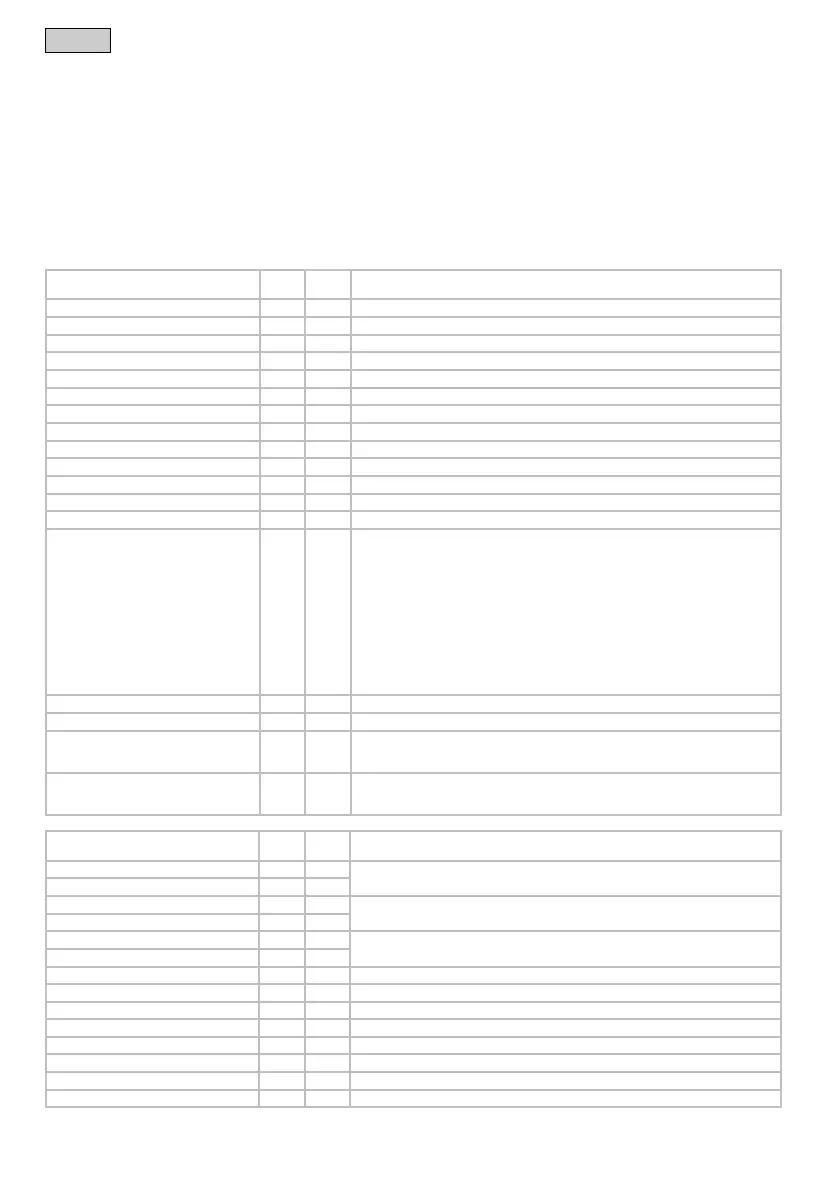

RDM parameters

General parameters GET

CMD

SET

CMD

Description

COMMS_STATUS

Shows general status information of the bus interface

STATUS_MESSAGES

Used to manage status messages

STATUS_ID_DESCRIPTION

Used to manage status messages

SUPPORTED_PARAMETERS

Overview of all RDM parameters

PARAMETER_DESCRIPTION

Description of all parameters

DEVICE_INFO

Brief overview of the most important features

PRODUCT_DETAIL_ID_LIST

Additional feature

DEVICE_MODEL_DESCRIPTION

Type designation

MANUFACTURER_LABEL

Manufacturer's designation

DEVICE_LABEL

Labelling field

SOFTWARE_VERSION_LABEL

Firmware version number

DMX_START_ADDRESS

Reading and setting the DMX start address

SENSOR_DEFINITION

Sensor information

SENSOR_VALUE

Sensor value

Sensor 1 TempLpErrorCount Temperature error counter, PCB

Sensor 2 TempWindErrorCount Temperature error counter, motor

Sensor 3 MotorFailureCount Motor failure counter

Sensor 4 ActualSpeed Current actual speed

Sensor 5 NominalSpeed Current set point speed

Sensor 6 PWM Current PWM value

Sensor 7 Temp Operating temperature, electronic board

Sensor 8 Winding Temp Operating temperature, motor

Sensor 9 Power Voltage Current intermediate circuit voltage

Sensor 10 Current Consumption Current intermediate circuit current

DEVICE_HOURS

Operating hour counter

DEVICE_POWER_CYCLES

Switch-on counter

IDENTIFY_DEVICE

0 = normal mode

1 = pump will switch on and off again at short intervals. This function is helpful for

identifying the device in the field.

RESET_DEVICE

Executes a reset.

1 = warm start

255 = cold start

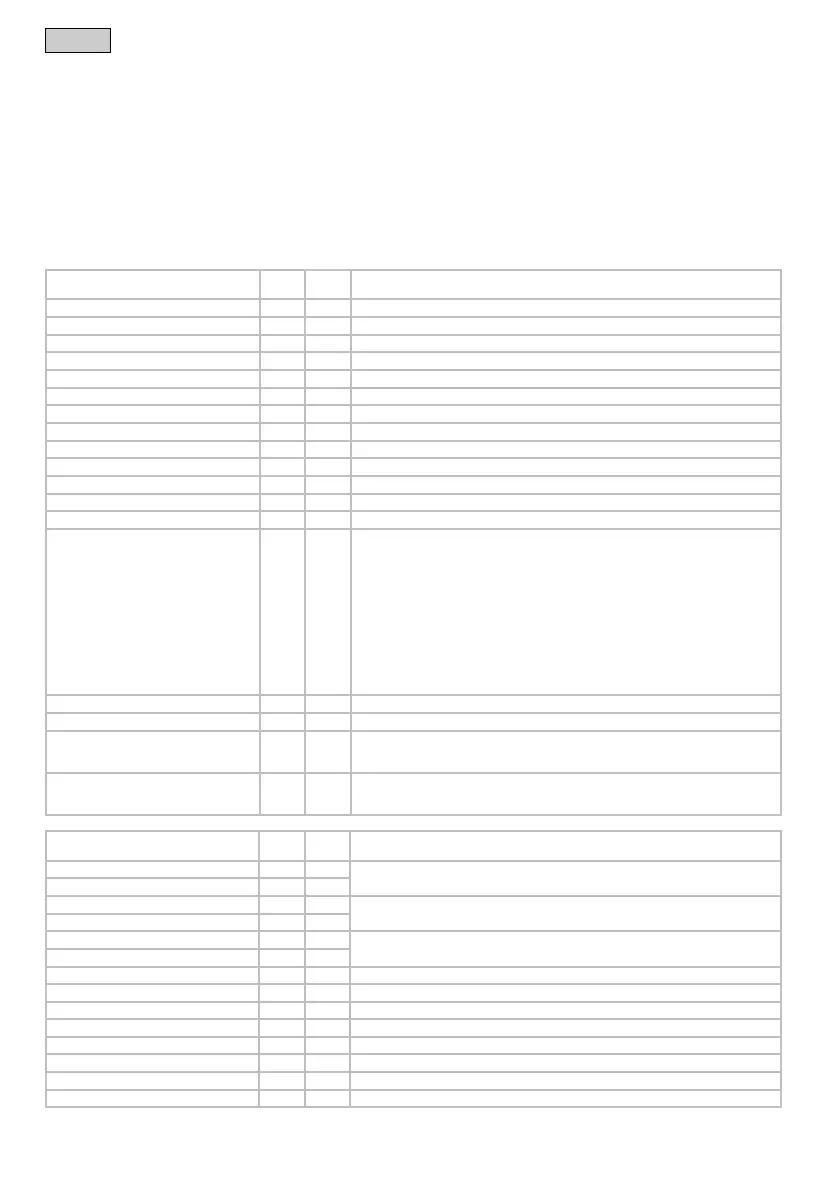

Specific parameters GET

CMD

SET

CMD

Description

KENNLINIENPUNKT_X1

Support value 1 of the stored pump characteristic curve

KENNLINIENPUNKT_Y1

KENNLINIENPUNKT_X2

Support value 2 of the stored pump characteristic curve

KENNLINIENPUNKT_Y2

KENNLINIENPUNKT_X3

Support value 3 of the stored pump characteristic curve

KENNLINIENPUNKT_Y3

RUNTIME_HOURS

Operating hour counter for the running period

STARTUP_COUNTER

Startup counter

CONFIG_MODE Only for service purposes

STS_OVERTEMP

Status message, overtemperature

STS_OVERVOLTAGE_PHASE

Status message, overvoltage

STS_UNDERVOLTAGE_PHASE

Status message, undervoltage

STS_OVERCURRENT

Status message, operating voltage too high

STS_BLOCKIERT

Status message, motor blocked

Loading...

Loading...