REGULATORS

DXI INTEGRATED FIRST STAGE

© 2002 Design 2000

OCEANICOCEANIC

OCEANICOCEANIC

OCEANIC®

Product Service Guide Product Service Guide

Product Service Guide Product Service Guide

Product Service Guide

Doc. 12-2205-r01 (01/00)

PG-8

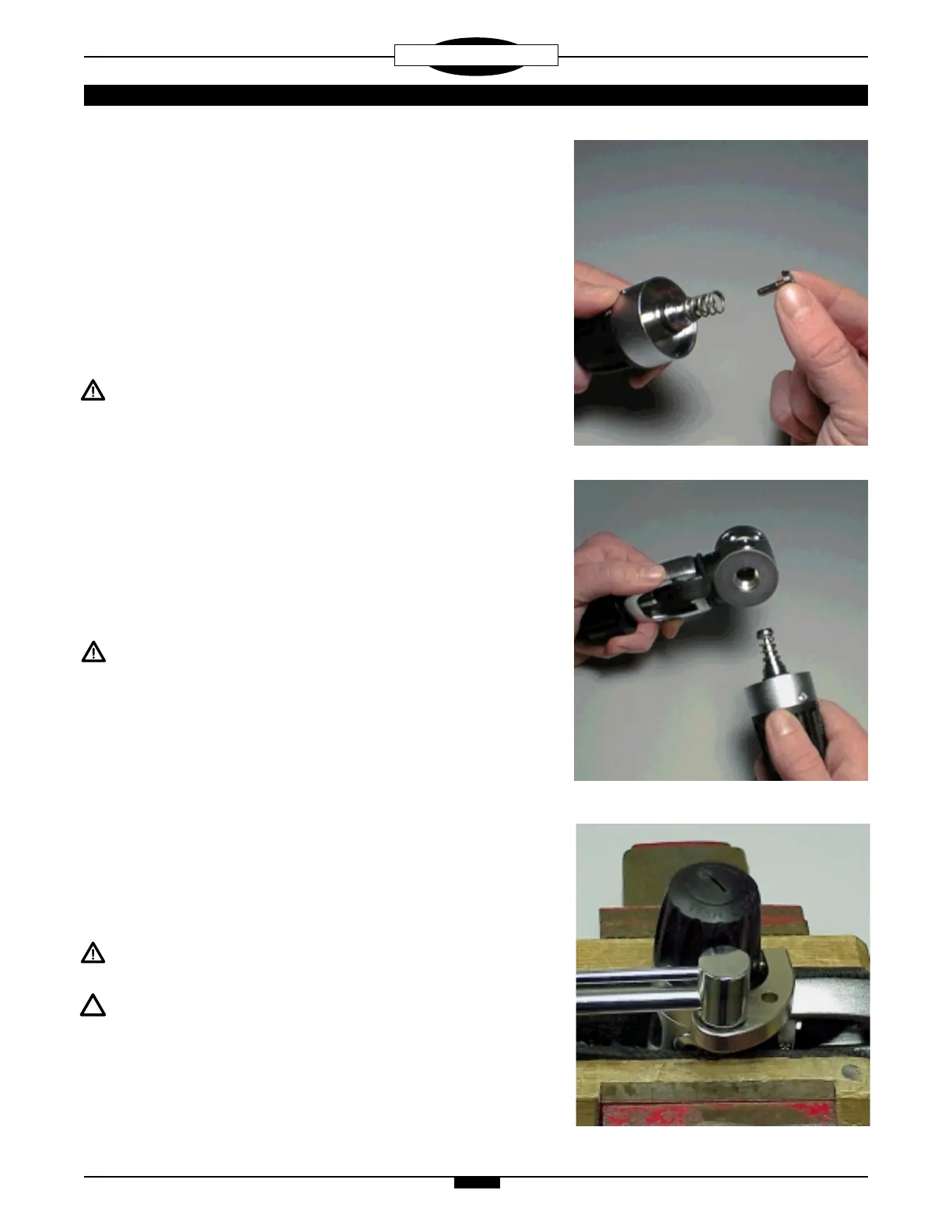

11. Carefully guide the shaft of the HP seat(27) so that it passes

through the spring(26) and into the seat o-ring(25) in the inner bore

of the transmitter(22). (Fig. 19)

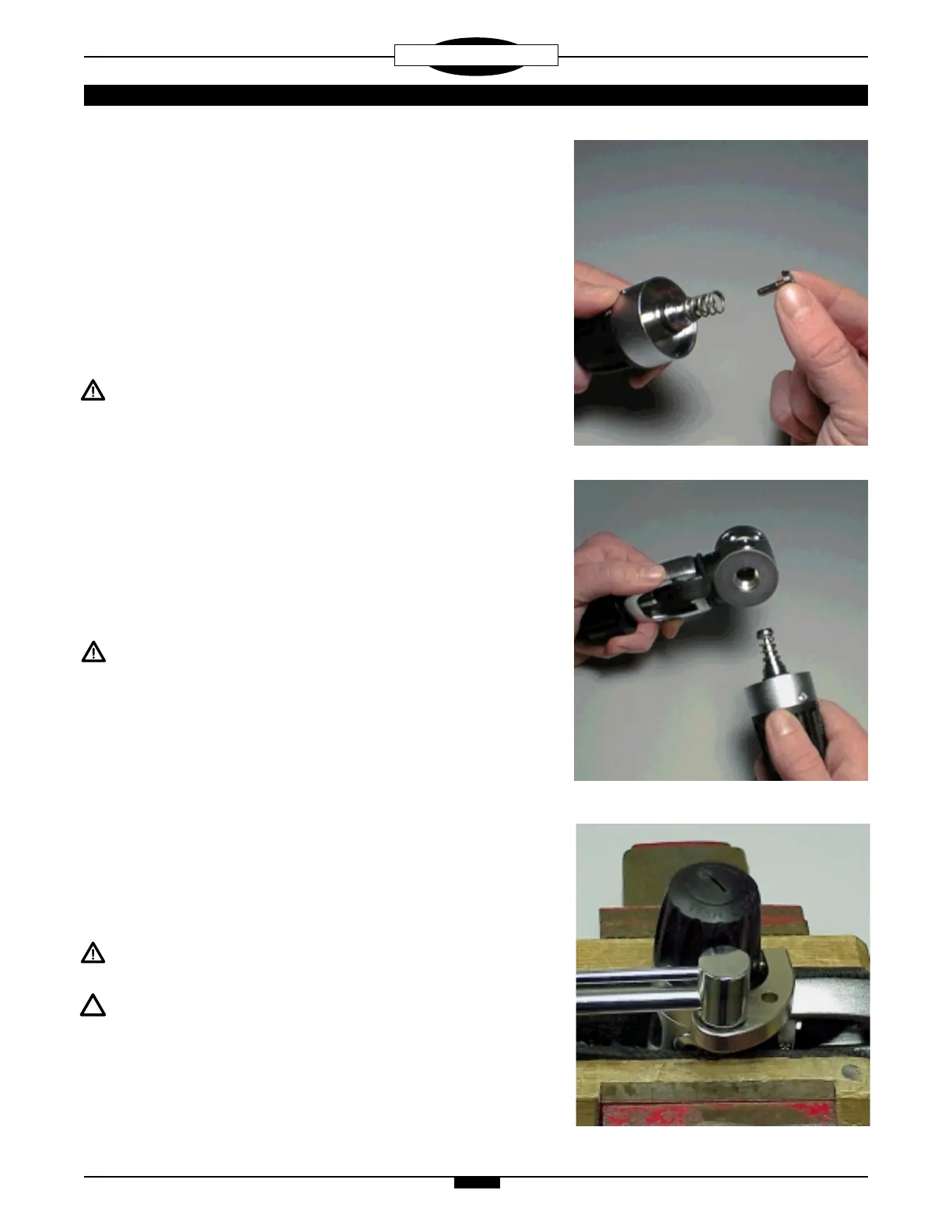

12. Hold the body(28) at a slight angle, so that you may see the stem

end of the button-pin(29) protruding through the center of the

machined orifice cone. Insert the transmitter/hp seat assembly

directly into the center of the opening in the body(28) and carefully

guide the center opening of the HP seat(27) onto the button pin(29).

Ensure the button-pin(29) enters directly into the opening of the HP

seat(27) without any restriction.(Fig. 20)

CAUTION: Improper alignment of the button-pin(29) and the

HP seat(27) during installation will result in damage to the

seating surface of the HP seat(27), requiring its replacement.

13. While holding the body (28) secure, turn the Transmitter/HP seat

assembly clockwise while exerting continuous inward force to

overcome spring pressure and engage the threads. Continue

tightening by hand until secure.

14. Secure the first stage body in a soft jawed or well padded vise.

Using a CDx Spanner on an inch-pounds torque wrench, tighten the

Transmitter assembly(22) into the body to a torque of 80 to 100

in-lbs. (Fig. 21)

CAUTION: Tighten the vise only as needed to hold the first

stage secure, and DO NOT overtighten. Doing so will result in

permanent damage, rendering it inoperable.

15. Lubricate and install port plug o-rings(19 & 21) onto the port

plugs(18 & 20) and install the port plugs into the body(28),

tightening clockwise with a 5/32" hex key socket to a torque of 35-

40 in-lbs.

16. Lubricate and install all hose o-rings onto hoses and install the

hoses into the body(28). Tighten the low pressure second stage

hose(s) clockwise with a 9/16" crows foot wrench, the high

pressure hose(s) with a 5/8" crows foot wrench, and the low

pressure inflator hose(s) with either a 9/16" or 1/2" crows foot

wrench, to a torque of 35-40 in-lbs.

CAUTION: Be certain not to install any low pressure hose into

a high pressure port via an adaptor.

NOTE: Perform step 17 only if an Environmental Protection Kit

has NOT been installed.

17. Ensuring proper alignment and secure placement, install the end

cap boot(36) onto the end cap(32).

Fig. 20

Fig. 19

Fig. 21

Loading...

Loading...