3

Operating Instructions and Parts Manual 24495

OSCILLATING TOOL

1/17

2017 OEMTOOLS

®

EXTENSION CORD SAFETY

WARNING

Keep the extension cord clear of the working area. Position the

cord so it will not get caught on the workpiece, tools or any other

obstructions while you are working with the power tool.

1. Make sure any extension cord used with this tool is in good condition.

When using an extension cord, be sure to use one of heavy enough

gauge to carry the current the tool will draw. An undersized cord will

cause a drop in line voltage resulting in loss of power and overheating.

2. The table below shows the correct size to use according to cord length

and nameplate ampere rating. If in doubt, use the next heavier gauge.

The smaller the gauge number the heavier the cord.

3. Be sure your extension cord is properly wired and in good

condition. Always replace a damaged extension cord or have it

repaired by a qualified electrician before using it. Protect your

extension cord from sharp objects, excessive heat and damp or

wet areas.

4. Use a separate electrical circuit for your power tools. This circuit

must not be less than 14 gauge wire and should be protected

with either a 15 A time delayed fuse or circuit breaker. Before

connecting the power tool to the power source, make sure the

switch is in the OFF position and the power source is the same as

indicated on the nameplate. Running at lower voltage will damage

the motor.

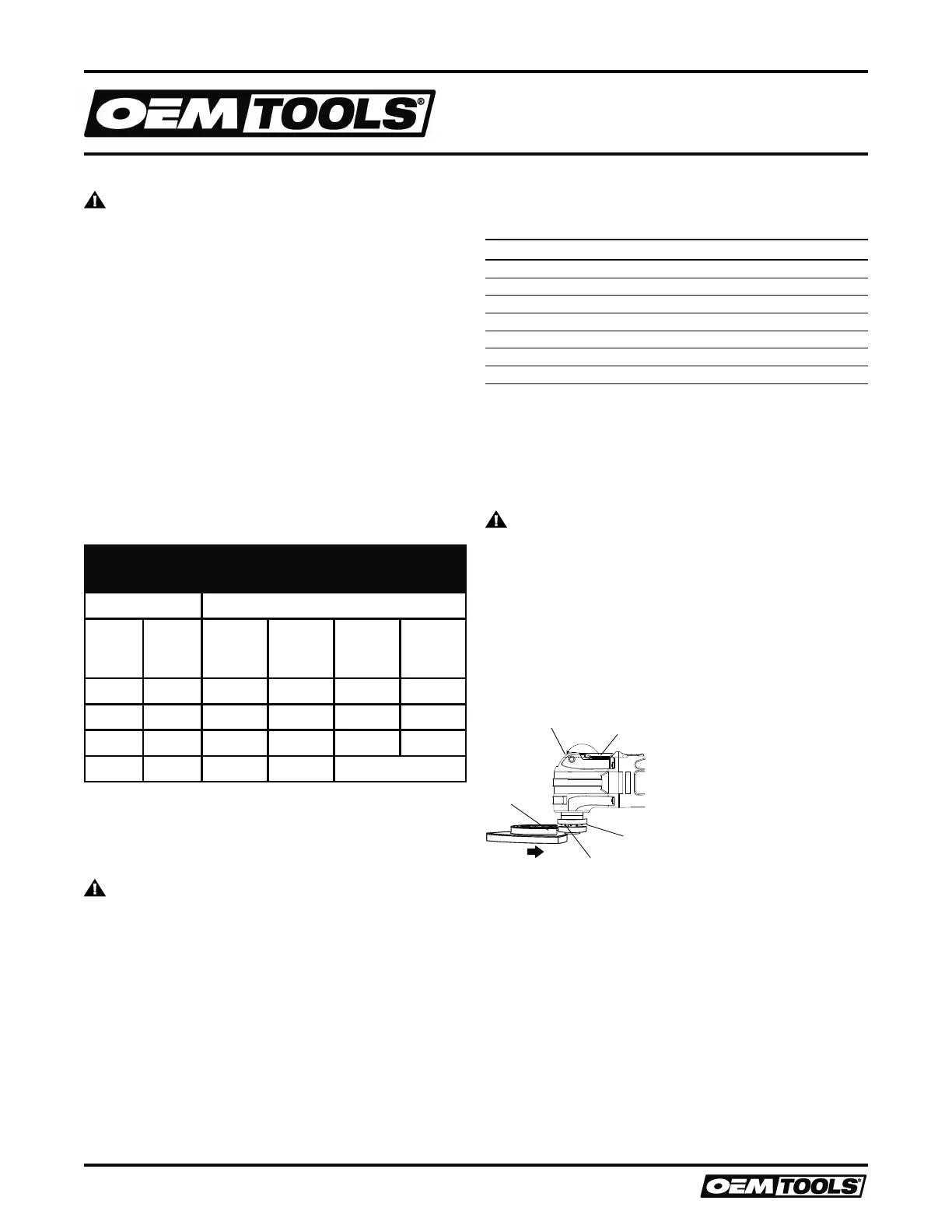

MINIMUM GAUGE (AWG) EXTENSION CORDS (120 V

use only)

Amperage rating Total length

More

than

Not

more

than

25'

(7.5 m)

50'

(15 m)

100'

(30 m)

150'

(45 m)

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Applicable

IMPORTANT SAFETY INSTRUCTIONS

The warnings, precautions, and instructions discussed in this manual cannot

cover all possible conditions and situations that may occur. The operator must

understand that common sense and caution are factors which cannot be built

into this product, but must be supplied by the operator.

WARNING

Use only attachments recommended or sold by manufacturer.

1. Do not disassemble the oscillating tool. Take it to a qualified professional

when service or repair is required. Incorrect reassembly may result in

electric shock or fire.

2. Wear approved safety eye/face shield, ear defenders and hand

protection.

DISPOSAL

At the end of the useful life of the OEMTOOLS

®

Oscillating Tool, dispose of

the components according to all state, federal and local regulations.

BATTERY DISPOSAL

Exposure to high temperatures can cause the batteries to explode; do not

dispose of in a fire. Some countries have regulations concerning battery

disposal. Follow all applicable regulations. Return used batteries to a

collection location for recycling. Call 800-822-8837 or visit

www.call2recycle.org to find a collection location.

PURPOSE

The OEMTOOLS

®

Oscillating Tool is used for removing delicate pieces of

trim. This tool is designed for many carpentry, electrical, plumbing, tile

repair jobs and most general household maintenance.

PRODUCT SPECIFICATIONS

Voltage: 120V, 60Hz

Variable Speed: 11,000 – 20,000 OPM

Power: 2.3 Amp

Oscillating Angle: 3.2 degrees

Overall Length: 14-1/2"

Power Cord Length: 6 Ft.

Weight: 4.1 Lbs.

INSTRUCTIONS

Always wear safety goggles and gloves.

NOTE: The drawings in the assembly and operating section of this manual

may differ slightly from the tool you purchased.

All accessories are installed on this oscillating tool in a similar manner.

For the purposes of describing the accessory installation, the triangular

sanding pad and a metal cutting blade have been illustrated.

WARNING

Always remove the plug from the power source before installing or

removing accessories or sandpaper. Failing to remove the plug from

the power source may result in the tool accidentally being started and

causing serious injury to the operator.

This oscillating tool has been designed for use with either open back

or closed back accessories. No tools are required to install open back

accessories. A 5mm hex key is required for installing closed back

accessories.

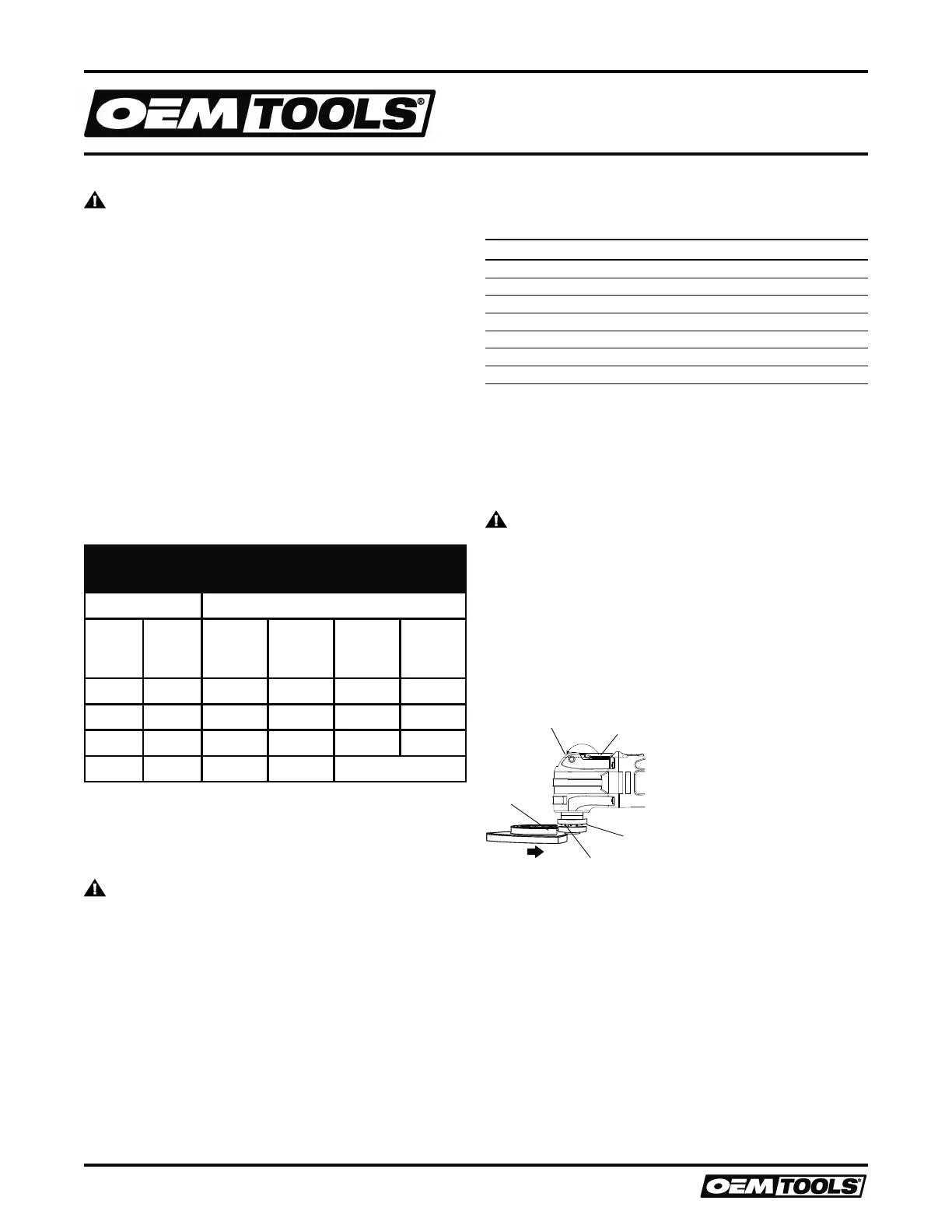

INSTALLING OPEN BACK ACCESSORIES

1. Lift the tool less accessory holder release lever (4) up and toward the

front of the tool as far as it will go (5). (Figure 1)

6

7

8

4

5

Fig. 4

1

2

Fig. 5

Fig. 3

1

2

3

4

5

6

7

8

9

10

Fig. 6

1

Fig. 7

1

Fig. 8

1

2

3

4

Fig. 9

1

2

Fig. 10

1

2

1

2

3

Fig. 11

Fig. 12

4

5

6

7

8

9

10

Figure 1

NOTE: This will open the tool less blade holder to accept the accessory.

2. Insert the accessory mount (7) into the opened accessory holder.

3. Align the accessory mounting slots and holes with the accessory

mounting teeth (8) in the accessory mount.

NOTE: The slots and holes in the accessory must be engaged with the

matching teeth on the accessory holder to allow the accessory to be

secured within the accessory holder.

4. Move the tool less accessory release lever back to its original position

(4) to clamp the accessory into the accessory holder.

NOTE: Check to make sure the accessory mounting pins are still aligned

with the slots and holes in the accessory mount.

Loading...

Loading...