4

Operating Instructions and Parts Manual 24495

OSCILLATING TOOL

1/17

2017 OEMTOOLS

®

INSTALLING SANDPAPER

1. Install the hook and loop sanding pad (1) onto the tool. (Figure 2)

Fig. 1

6

7

8

Fig. 2

4

5

Fig. 4

1

2

Fig. 5

Fig. 3

1

2

3

4

5

6

7

8

9

10

Fig. 6

1

Fig. 7

1

Fig. 8

1

2

3

4

Fig. 9

1

2

Fig. 10

1

2

1

2

3

Fig. 11

Fig. 12

4

5

6

7

8

9

10

Figure 2

2. Firmly press the sandpaper (2) onto the hook and loop pad.

NOTES: Place the sandpaper so the holes in the sandpaper line up with

the matching holes in the hook and loop pad. Press the sandpaper firmly

onto the hook and loop pad.

3. To remove the sandpaper, simply peel the sandpaper away from the

hook and loop pad. (Figure 3)

Fig. 1

6

7

8

Fig. 2

4

5

Fig. 4

1

2

Fig. 5

Fig. 3

1

2

3

4

5

6

7

8

9

10

Fig. 6

1

Fig. 7

1

Fig. 8

1

2

3

4

Fig. 9

1

2

Fig. 10

1

2

1

2

3

Fig. 11

Fig. 12

4

5

6

7

8

9

10

Figure 3

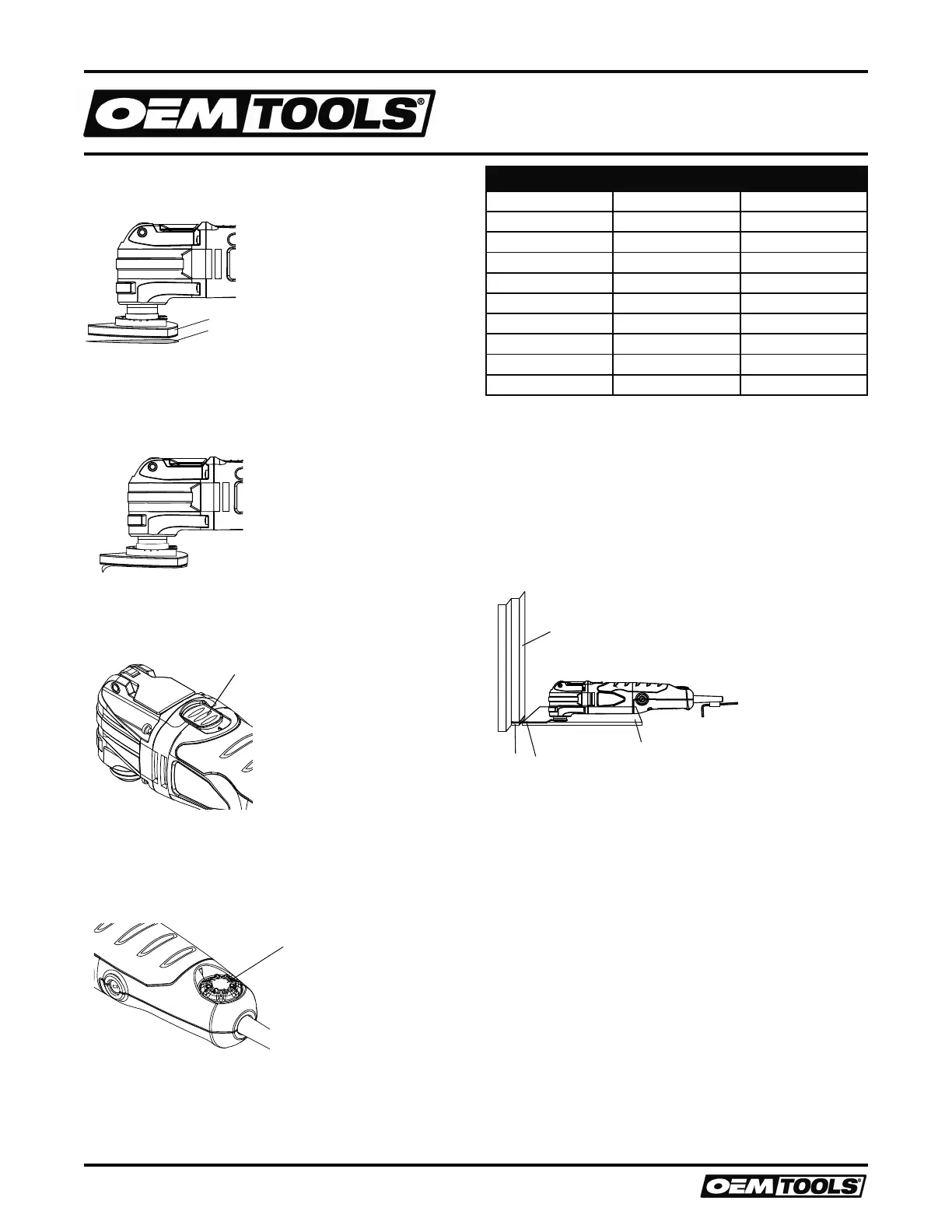

ON/OFF SWITCH

1. To turn the tool ON, slide the ON/OFF switch (1) toward the front of the

tool. (Figure 4)

Fig. 1

6

7

8

Fig. 2

4

5

Fig. 4

1

2

Fig. 5

Fig. 3

1

2

3

4

5

6

7

8

9

10

Fig. 6

1

Fig. 7

1

Fig. 8

1

2

3

4

Fig. 9

1

2

Fig. 10

1

2

1

2

3

Fig. 11

Fig. 12

4

5

6

7

8

9

10

Figure 4

2. To turn the tool OFF, slide the ON/OFF switch toward the rear of the tool.

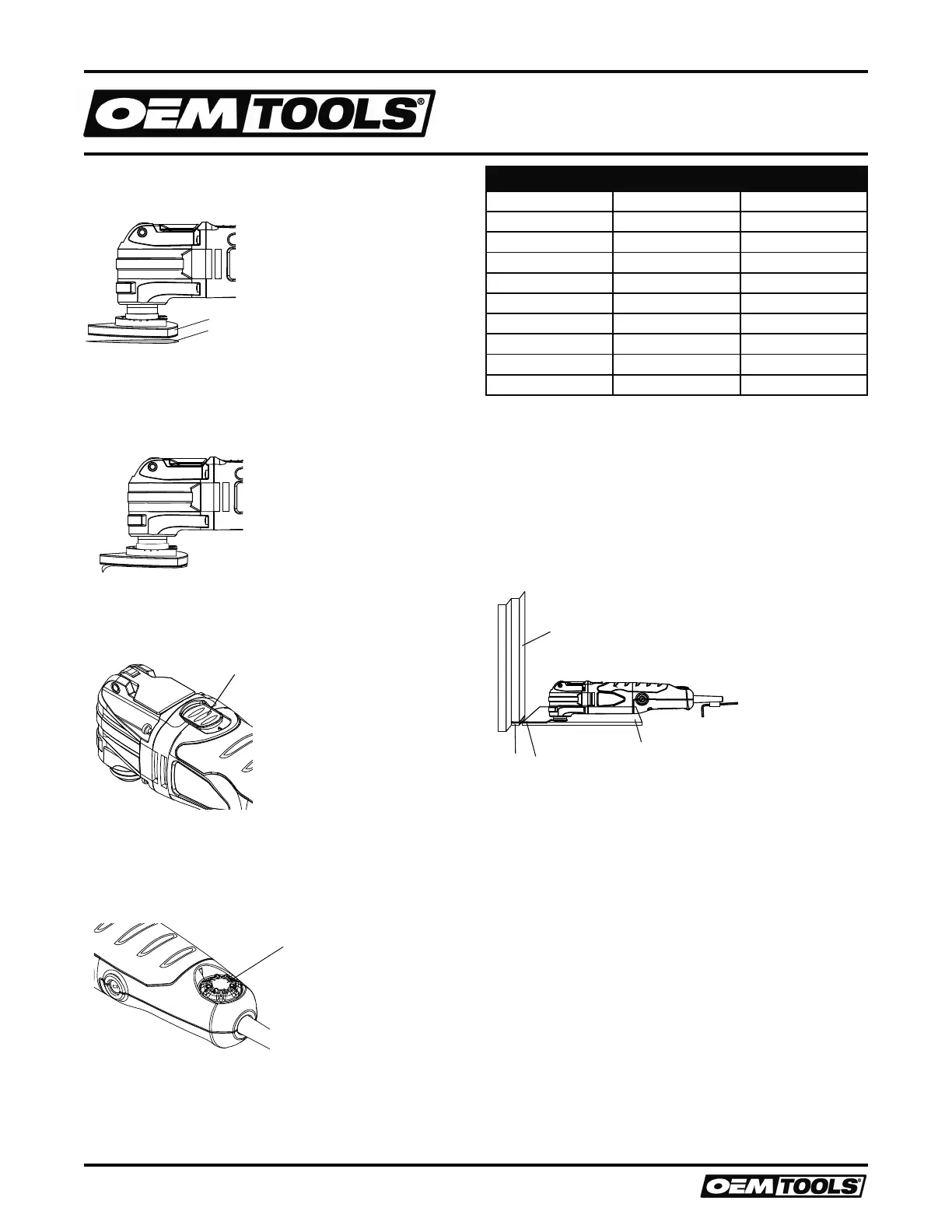

SPEED CONTROL WHEEL

NOTE: The speed of the tool can be adjusted to run the tool at speeds

varying between 11,000 - 20,000 OPM by rotating the speed control

wheel (1) located toward the rear of the tool housing. (Figure 5)

Fig. 1

6

7

8

Fig. 2

4

5

Fig. 4

1

2

Fig. 5

Fig. 3

1

2

3

4

5

6

7

8

9

10

Fig. 6

1

Fig. 7

1

Fig. 8

1

2

3

4

Fig. 9

1

2

Fig. 10

1

2

1

2

3

Fig. 11

Fig. 12

4

5

6

7

8

9

10

Figure 5

1. To increase the speed, rotate the speed control wheel to the right.

2. To decrease the speed, rotate the speed control wheel to the left.

NOTE: Speed #1 is the lowest speed. “MAX” is the highest speed. The

optimal speed setting will vary depending upon the type of accessory

being used, the surface being worked and the complexity of the project.

For general recommendations, see the chart below.

Project Accessory Speed

Balsa Wood Wood Blade Low

Drywall Half-Circle Blade Maximum

Restoring Windows Half-Circle Blade Medium

Door Jamb Wood Blade Maximum

Door Casing Wood Blade Medium / Maximum

Wood Dowels Wood Blade Maximum

Floor Vent Wood Blade Medium / Maximum

PVC Pipe Wood Blade Medium

Glued Flooring Scraper Medium

Sanding Sander Medium / Maximum

FLUSH CUTTING A DOOR JAM AND CASING FOR INSTALLING

FLOORING

The oscillating tool can be used to flush cut a door jamb and casing to

allow space for the new flooring to fit neatly under the door jamb and

casing. For the purpose of demonstrating the procedure, floor tile is being

used.

1. Install the wood plunge cut saw blade in the tool. (Figures 1 and 2)

NOTE: The blade should be centered on the tool housing and NOT

installed in the 90° position.

2. Place a scrap piece of floor tile (1) on the floor about 1/2" (12.5 mm)

from the door jamb (2). (Figure 6)

Fig. 1

6

7

8

Fig. 2

4

5

Fig. 4

1

2

Fig. 5

Fig. 3

1

2

3

4

5

6

7

8

9

10

Fig. 6

1

Fig. 7

1

Fig. 8

1

2

3

4

Fig. 9

1

2

Fig. 10

1

2

1

2

3

Fig. 11

Fig. 12

4

5

6

7

8

9

10

Figure 6

NOTE: Make sure the “good” side of the tile is facing upward to provide a

smooth surface for the blade (3) to follow.

3. Place the tool with the saw blade lightly touching the surface of the tile

and the cutting teeth NOT touching the surface to be cut.

4. Set the speed to the fastest speed. (Figure 5)

5. Turn the tool ON. (Figure 4)

6. When the tool reaches its maximum set speed, carefully plunge the

blade into the door jamb while sliding the blade along the floor tile.

NOTE: Hold the tool tightly and do not put too much forward pressure

on the saw blade when cutting, as this will cause the tool to vibrate

excessively.

7. Continue to make several plunge cuts until the bottom of the door jamb

and casing are completely cut off and the loose pieces (4) can be easily

removed.

NOTE: Follow the same basic procedure for installing carpet, using a

thicker spacer that is the same thickness of the carpet being installed.

Loading...

Loading...