4

Operating Instructions and Parts Manual 24840

6/18

2018 OEMTOOLS

™

1,000 LB. TELESCOPIC

TRANSMISSION JACK

13. Before each use, inspect the general condition of the

Transmission Jack. Check for oil leaks, jack operation,

loose components, free rotation and pivoting of saddle

adjustment components. If a problem occurs, have the

problem corrected before further use.

TO PREVENT SERIOUS INJURY:

DO NOT USE A DAMAGED OR

MALFUNCTIONING JACK

14. Make sure the casters are blocked before use.

15. The Transmission Jack is not designed to lift or lower

a vehicle.

16. If in doubt about the safety of your project, we advise

you to have the work done by a professional familiar

with applicable safety practices.

ASSEMBLY

1. Attach both Legs to Support Post using (2) M10 x 100

mm Bolts, (4) M10 Washers and M10 x 1.5 mm Lock

Nuts, inserting Bolts through upper holes in Legs and

through Support Post, making sure lower holes in Legs

align with lower holes in Support Post. Do not fully tighten.

2. Install (4) M10 x 25 mm Bolts, (8) M10 Washers, and (4)

M10 x 1.5 mm Lock Nuts through lower holes in each

Leg. DO NOT fully tighten.

3. Lay assembly on its side and attach (4) Casters using

(4) M12 Lock Nuts. Securely tighten.

4. Stand unit up. Ensure Support Post is perpendicular to

the Legs, and then fully tighten all 6 Leg Bolts and Nuts.

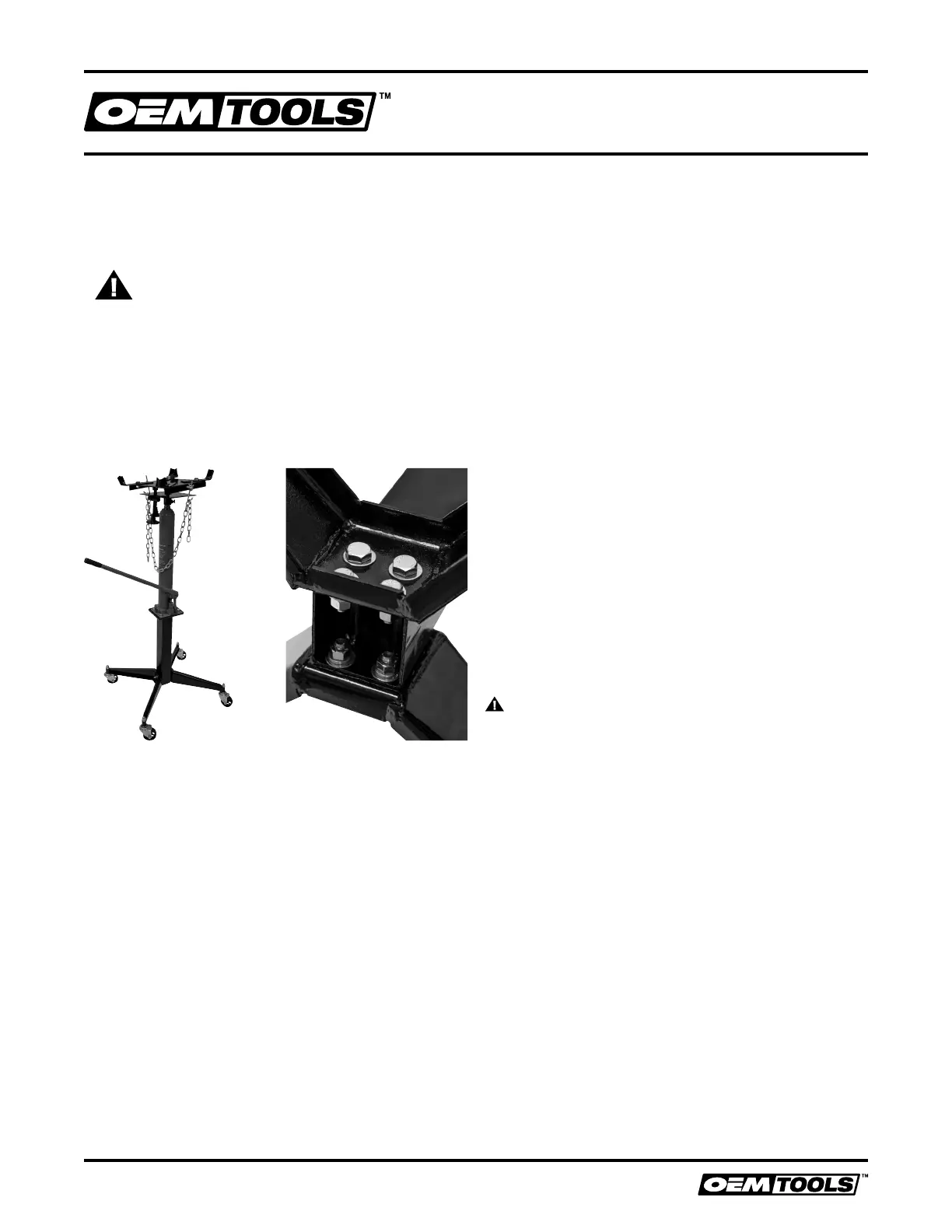

5. Attach Ram to Support Post using (4) M12x30 mm

Bolts, (8) M12 Washers and (4) M12 Lock Nuts.

6. Attach Transmission Adapter to Ram and tighten

Clamp Bolt. DO NOT overtighten.

7. Attach Slides, Safety Blocks and Chains and adjust

as necessary.

OPERATION

1. Follow the instruction for removal and installation of

transmission, transfer case or transaxle according to

the vehicle manufacturer’s service manual.

2. Prior to initial use, jack up the Saddle and, using

the Release Knob, attempt to lower it. Doing so will

familiarize the user with the control functions and jack.

3. Once the vehicle is safely and properly secured,

position the Transmission Jack underneath the vehicle.

4. Pump the Handle to raise the jack to contact and

bear transmission weight. After making contact with

the transmission, make sure it is centered within the

brackets on the Saddle Plate. Use Adjustment Knobs

to position the Saddle Base.

5. After contact, lift the jack slightly to transfer the weight

of the transmission from the vehicle chassis to the

Transmission Jack.

6. Remove transmission fasteners, freeing it from the

vehicle. Make sure there is nothing to restrict the

movement of the transmission.

7. Back transmission away to free from engine.

8. Check the Saddle, making sure it is securely holding

and aligned with the transmission and not showing

any signs of stress. Carefully lower transmission and

Saddle by turning the Release Knob.

9. Secure the Chain tightly over the transmission and

safely move the Transmission Jack.

10. After removal, lower the jack to the lowest possible point.

WARNING: The jack is designed to lift loads only for

short periods of time. DO NOT use to suspend a load for

more than 30 minutes at a time.

11. To re-mount the transmission, reverse this procedure.

MAINTENANCE

IMPORTANT: Use only good quality hydraulic jack oil.

Avoid mixing different types of fluid and NEVER use brake

fluid, turbine oil, transmission fluid, motor oil or glycerin.

Improper fluid can cause premature failure of the jack and

the potential for sudden and immediate loss of load.

ADDING OIL

1. With saddle fully lowered, set jack in its upright, level

position. Remove oil filler plug.

2. Fill until oil is level with the oil filler hole, reinstall oil

filler plug.

CHANGING OIL

For best performance and longest life, replace the

complete fluid supply at least once per year.

1. With saddle fully lowered, remove oil filler plug.

2. Lay the jack on its side and drain the fluid into a

suitable container.

Loading...

Loading...