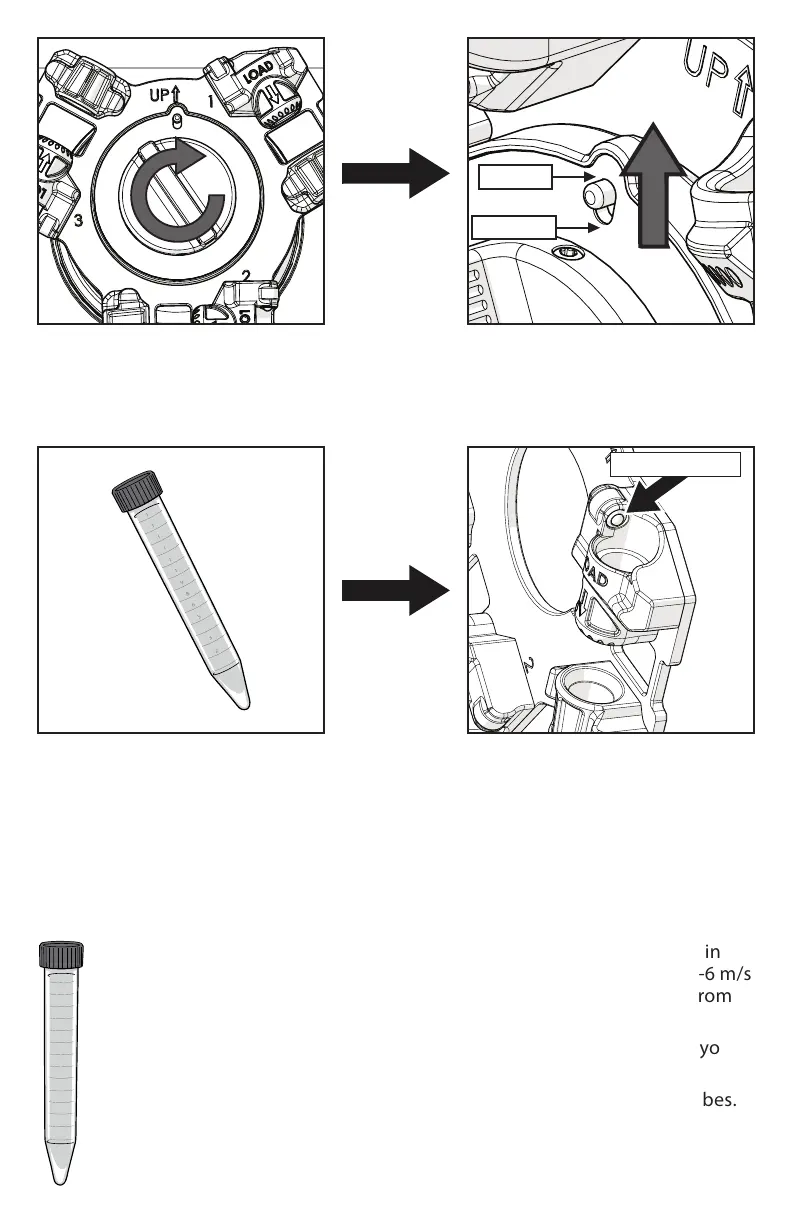

3. Turn lock ring clockwise

until tight.

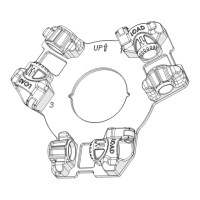

5. Fill tube with material

to be homogenized.

NOTE: 5-10 mL is the optimal

volume of uid to eciently

homogenize most samples.

6. Fully insert tube into

the tube holder until the

tube cap is seated under

the Spring Plunger*.

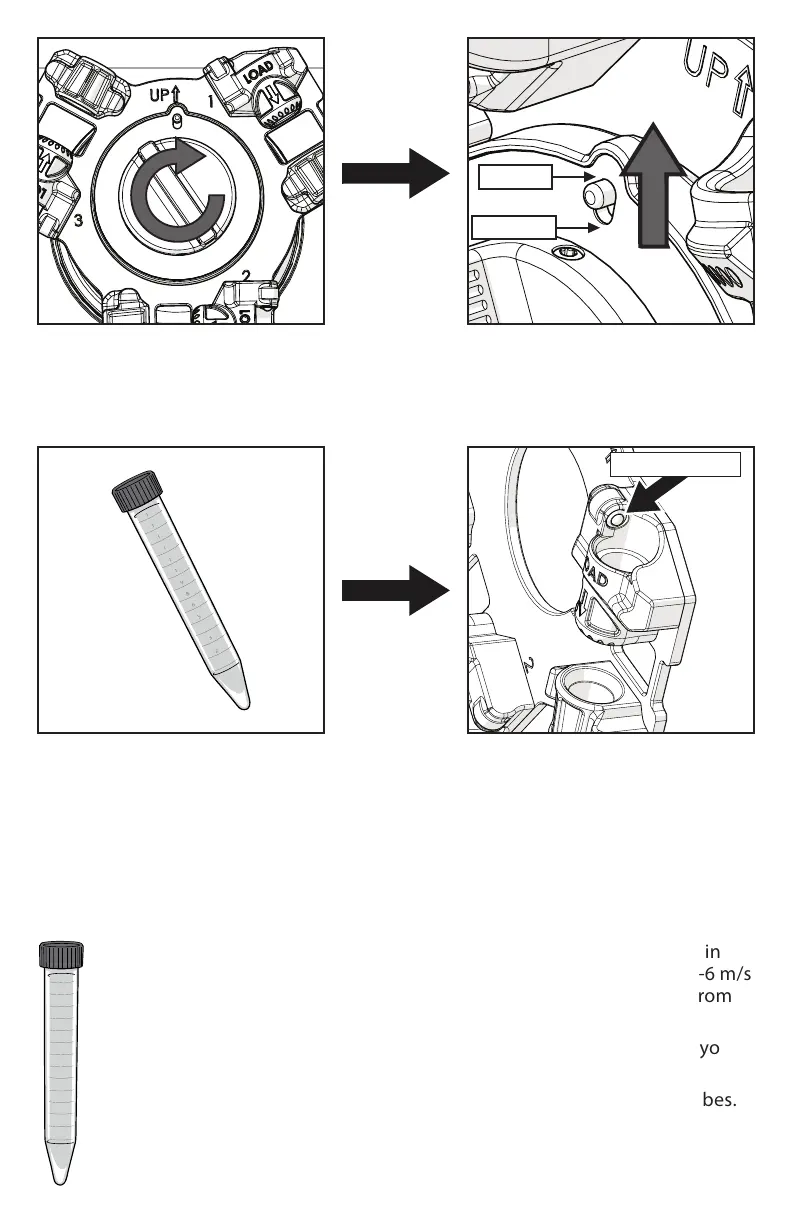

WARNING: The 15 mL tube carriage should not be operated at speeds in

excess of 6 m/s. Eective processing can be achieved at speeds from 3-6 m/s

for most applications. At speeds above 6 m/s, tubes could be ejected from

the tube carriage.

WARNING: The 15 mL Tube Carriage is NOT compatible with the BR Cryo

Cooling Unit.

TUBE COMPATIBILITY: Only use Omni International 15 mL conical tubes.

The 15 mL Tube Carriage has been optimized for this tube geometry.

4. Ensure lock mechanism

is fully engaged.

WARNING: Lock mechanism must be

secured entirely in the locked position.

Locked

Unlocked

m

m

m

m

4 m

m

1 m

m

m

m

m

4 m

m

1 m

*Spring Plunger

Loading...

Loading...