3-56

3-3 Servomotor Specifications

OMNUC G5-series AC Servomotors and Servo Drives User’s Manual (with Built-in EtherCAT Communications)

3

Specifications

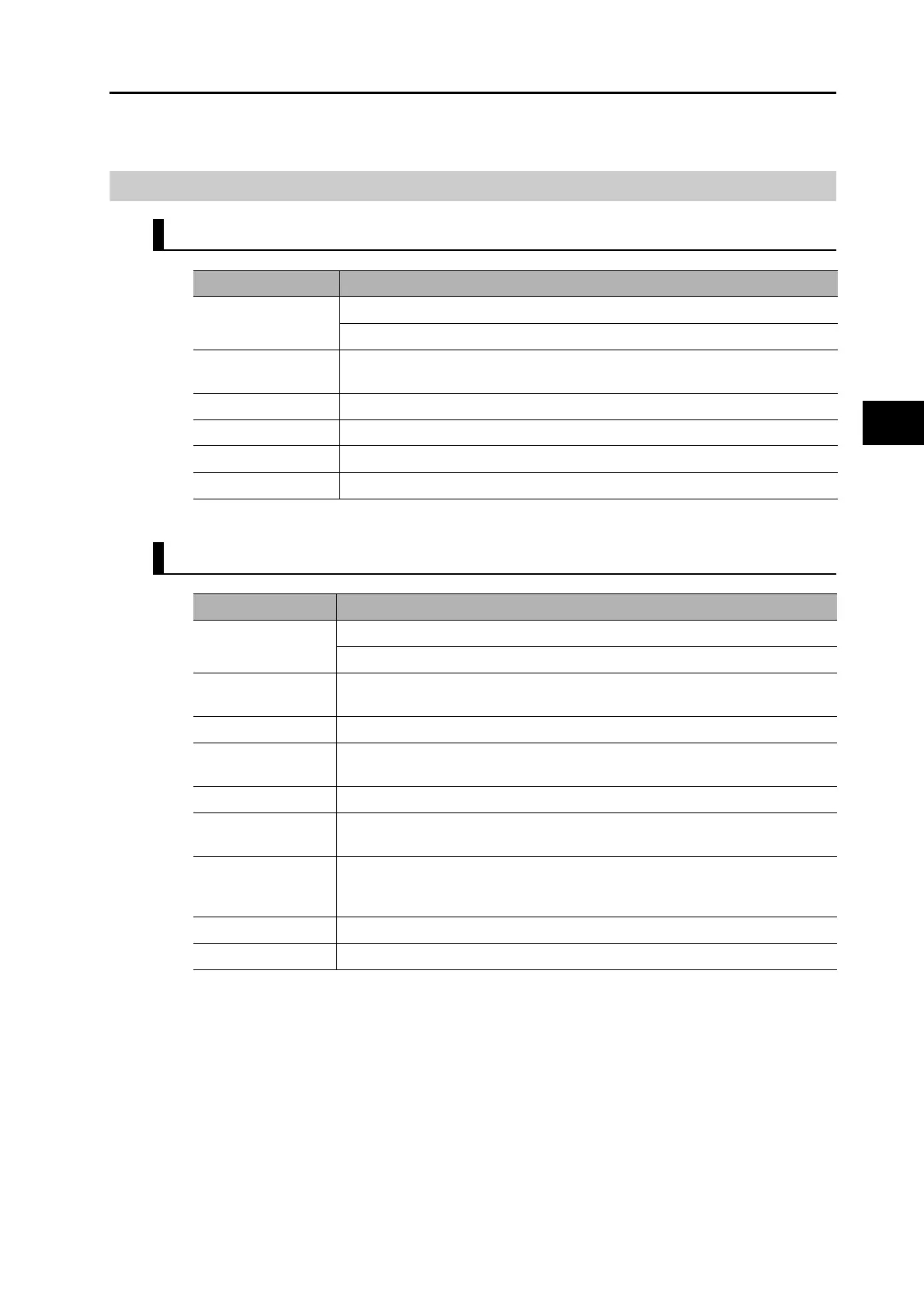

Encoder Specifications

Incremental Encoder Specifications

Absolute Encoder Specifications

Note: Multi-rotation Data Backup

• The multi-rotation data will be lost if the battery cable connector is disconnected at the

motor when connecting the battery cable for the absolute encoder and battery.

• The multi-rotation data will be lost if CN2 is disconnected when connecting the battery

to CN1.

Item Specifications

Encoder system Optical encoder

20 bits

Number of output

pulses

Phases A and B: 262,144 pulses/rotation

Phase Z: 1 pulse/rotation

Power supply voltage 5 VDC ± 5%

Power supply current 180 mA (max.)

Output signal +S, −S

Output interface RS485 compliant

Item Specifications

Encoder system Optical encoder

17 bits

Number of output

pulses

Phases A and B: 32,768 pulses/rotation

Phase Z: 1 pulse/rotation

Maximum rotations −32,768 to +32,767 rotations

Power supply

voltage

5 VDC ± 5%

Power supply current 110 mA (max.)

Applicable battery

voltage

3.6 VDC

Current consumption

of battery

265 µA (for a maximum of 5 s right after power interruption)

100 µA (for operation during power interruption)

3.6 µA (when power is supplied to the drive)

Output signal +S, −S

Output interface RS485 compliant