A

poor batteQ causes problems and should be

checked first during electrical system

troubleshooting

or

maintenance. The better the care,

the longer all components will last and the more

profitable, trouble-free service you’ll receive.

Regulator-Rectifier

To see if the regulator is performing satisfactorily,

place a DC voltmeter across the battery terminals with

the engine NOT running. Record this voltage. Then

start the engine and accelerate to afast idle

(1

800

rpm

or

higher). If the voltage does not rise from original

reading after a few minutes, the system is not

operating

properly, and the regulator should be

suspected. However, check the alternator output

before concluding that the regulator is at fault.

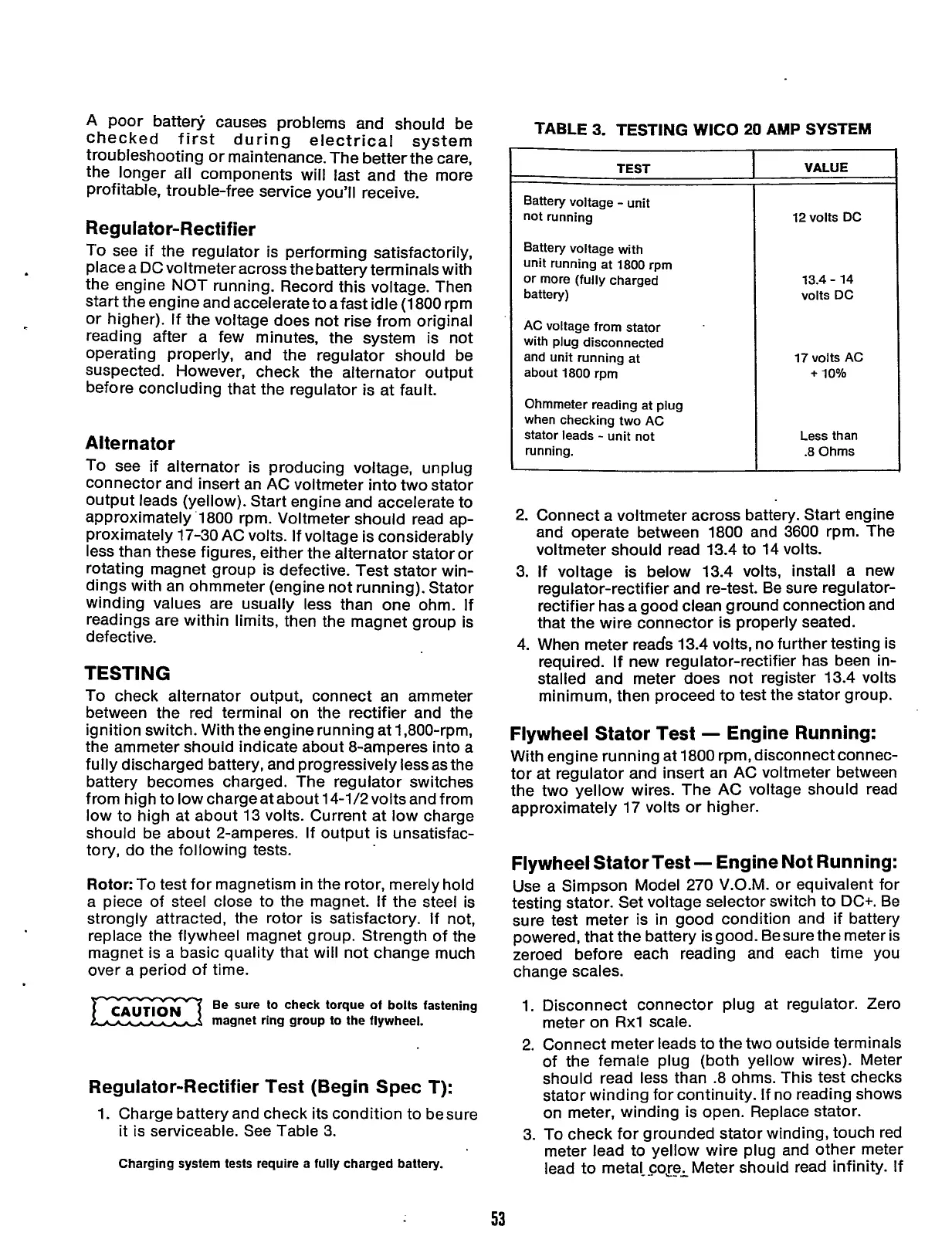

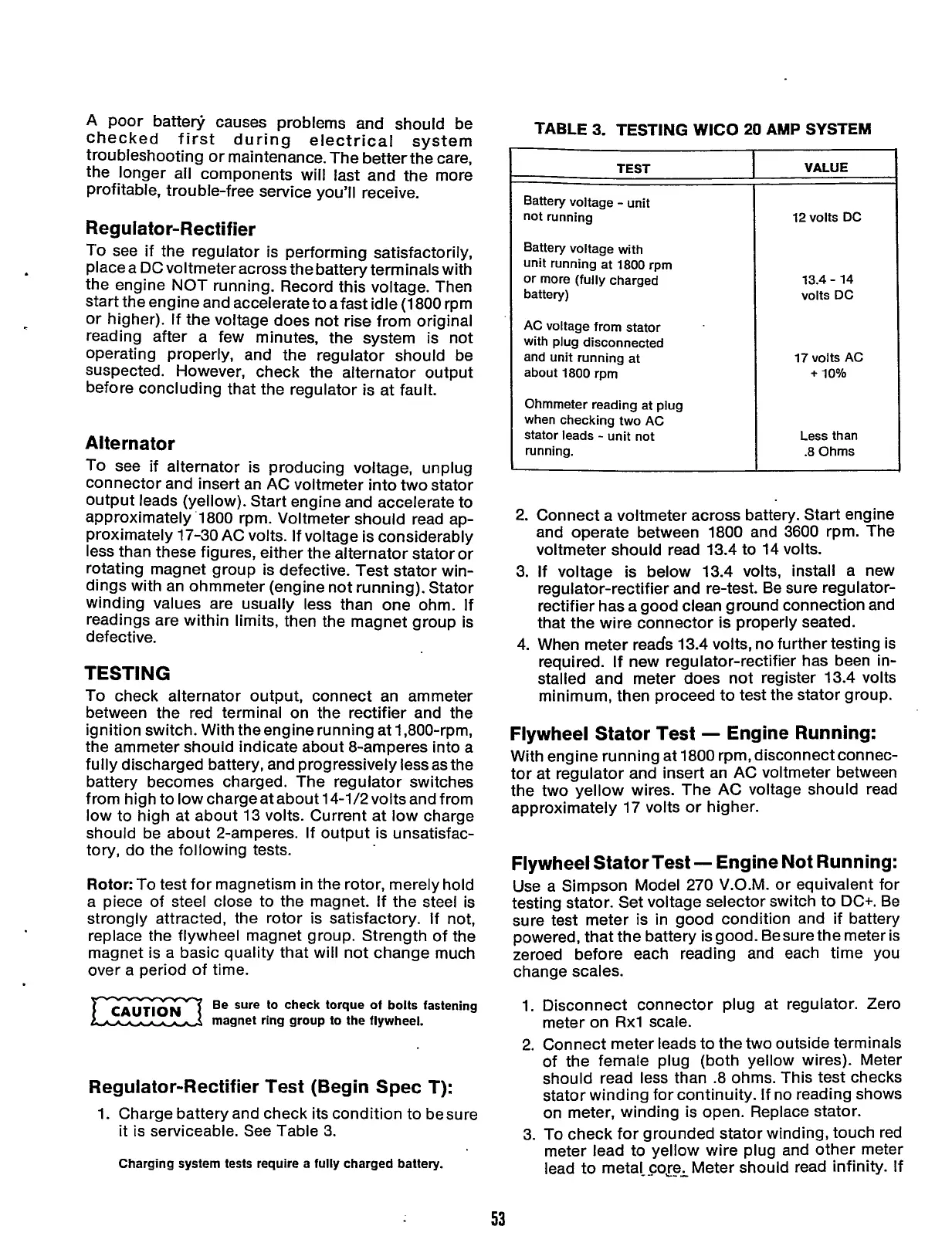

TEST

Alternator

To see if alternator is producing voltage, unplug

connector and insert an

AC

voltmeter into two stator

output leads (yellow). Start engine and accelerate to

approximately

.I800

rpm. Voltmeter should read ap-

proximately 17-30 AC volts. If voltage is considerably

less than these figures, either the alternator stator or

rotating magnet group is defective. Test stator win-

dings with an ohmmeter (engine not running). Stator

winding values are usually less than one ohm. If

readings are within limits, then the magnet group is

defective.

VALUE

TESTING

To

check alternator output, connect an ammeter

between the red terminal on the rectifier and the

ignition switch. With the engine running at

1

,800-rpm,

the ammeter should indicate about 8-amperes into a

fully discharged battery, and progressively less as the

battery becomes charged. The regulator switches

from high to

lowchargeatabout14-1/2voltsandfrom

low to high at about 13 volts. Current at low charge

should be about 2-amperes. If output is unsatisfac-

tory, do the following tests.

Rotor:

To

test for magnetism in the rotor, merely hold

a piece of steel close to the magnet. If the steel is

strongly attracted, the rotor is satisfactory.

If

not,

replace the flywheel magnet group. Strength of the

magnet

is

a basic quality that will not change much

over a period of time.

Be sure to check torque

of

bolts fastening

magnet ring group to the flywheel.

Regulator-Rectifier Test (Begin Spec

T):

1.

Charge battery and check its condition to besure

it is serviceable. See Table 3.

Charging system tests require a fully charged battery.

Battery voltage

-

unit

not running

Battery voltage with

unit running at 1800 rpm

or more

(fully

charged

battery)

AC voltage from stator

with plug disconnected

and unit running at

about 1800 rpm

Ohmmeter reading at plug

when checking two AC

stator leads

-

unit not

running.

12 volts DC

13.4

-

14

volts DC

17 volts AC

i

10%

Less than

.8 Ohms

2. Connect a voltmeter across battery. Start engine

and operate between

1800

and 3600 rpm. The

voltmeter should read 13.4 to

14

volts.

3. If voltage is below 13.4 volts, install a new

regulator-rectifier and re-test. Be sure regulator-

rectifier has a good clean ground connection and

that the wire connector is properly seated.

4.

When meter reads

13.4

volts, no further testing is

required. If new regulator-rectifier has been in-

stalled and meter does not register 13.4 volts

minimum, then proceed to test the stator group.

Flywheel Stator Test

-

Engine Running:

With engine running at

1800

rpm, disconnect connec-

tor at regulator and insert an

AC

voltmeter between

the two yellow wires. The

AC

voltage should read

approximately 17 volts

or

higher.

Flywheel StatorTest

-

Engine Not Running:

Use a Simpson Model 270 V.O.M. or equivalent for

testing stator. Set voltage selector switch to DC+. Be

sure test meter is in good condition and if battery

powered, that the battery is good. Be sure the meter is

zeroed before each reading and each time you

change scales.

1.

Disconnect connector plug at regulator. Zero

meter on

Rxl

scale.

2. Connect meter leads to the two outside terminals

of the female plug (both yellow wires). Meter

should read less than

.8

ohms. This test checks

stator winding for continuity.

If

no reading shows

on meter, winding is open. Replace stator.

3. To check for grounded stator winding, touch red

meter lead to yellow wire plug and other meter

lead to meta!-coIer Meter should read infinity. If

53

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...