Thoroughly clean and inspect the c:ank%aft and

blow out all oil passages with compressed air. Check

all journals for out-of-round, taper, grooving or

ridges. Pay particular attention to ridges or grooves

on either side

of

the oil hole areas which indicate

neglect of oil cleanliness.

If the journal dimensions are not within the limk, or

the journals are scored,

machine the crankshaft.

Crankshaft machining requires a trained and ex-

perienced operator and suitable equipment.

Undersize bearings and connecting rods are available

to

rework the shaft to

.010”,

.020”

and

.030”

under-

size.

If main bearing clearances are greater than the limits

or the bearings are worn, grooved or broken, replace

them. Precision replacement bearing inserts and

thrust washers are available for all main bearings.

Do

not ream the precision type bearings. Refer to

Diiiiensiotis

arid Clrararices

for cran ksh af t tolerances.

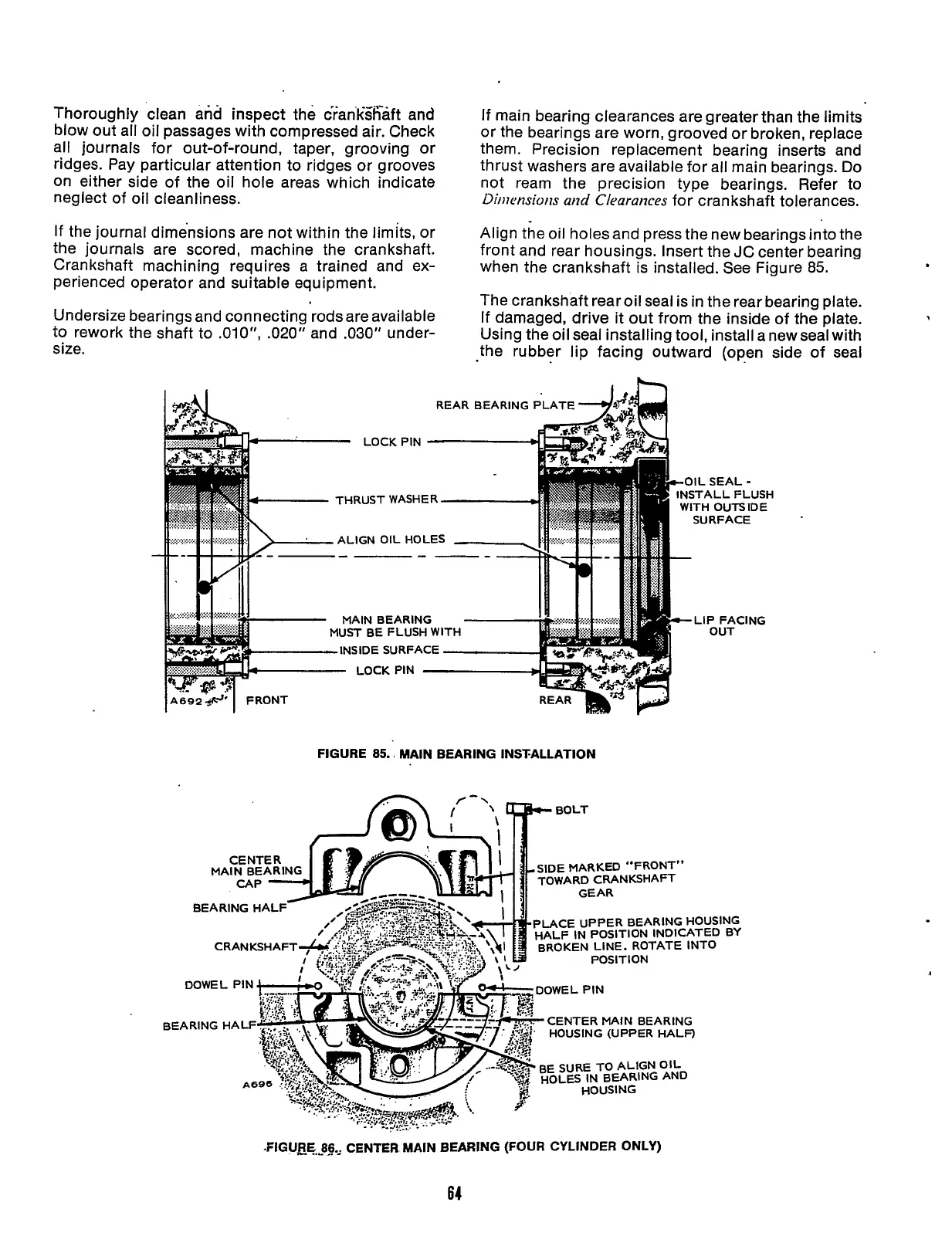

Align the oil holesand press the new bearings into the

front and rear housings. Insert the

JC

center bearing

when the crankshaft is installed. See Figure

85.

The crankshaft rearoil seal is in the rear bearing plate.

If damaged, drive it out from the inside of the plate.

Using the oil seal installing tool, install anew seal with

the rubber lip facing outward (open side of seal

THRUST WASHER

ALIGN

OIL

HOLES

MAIN BEARING

INSIDE SURFACE

MUST BE FLUSH WITH

FIGURE

85.,

MAIN BEARING INSTALLATION

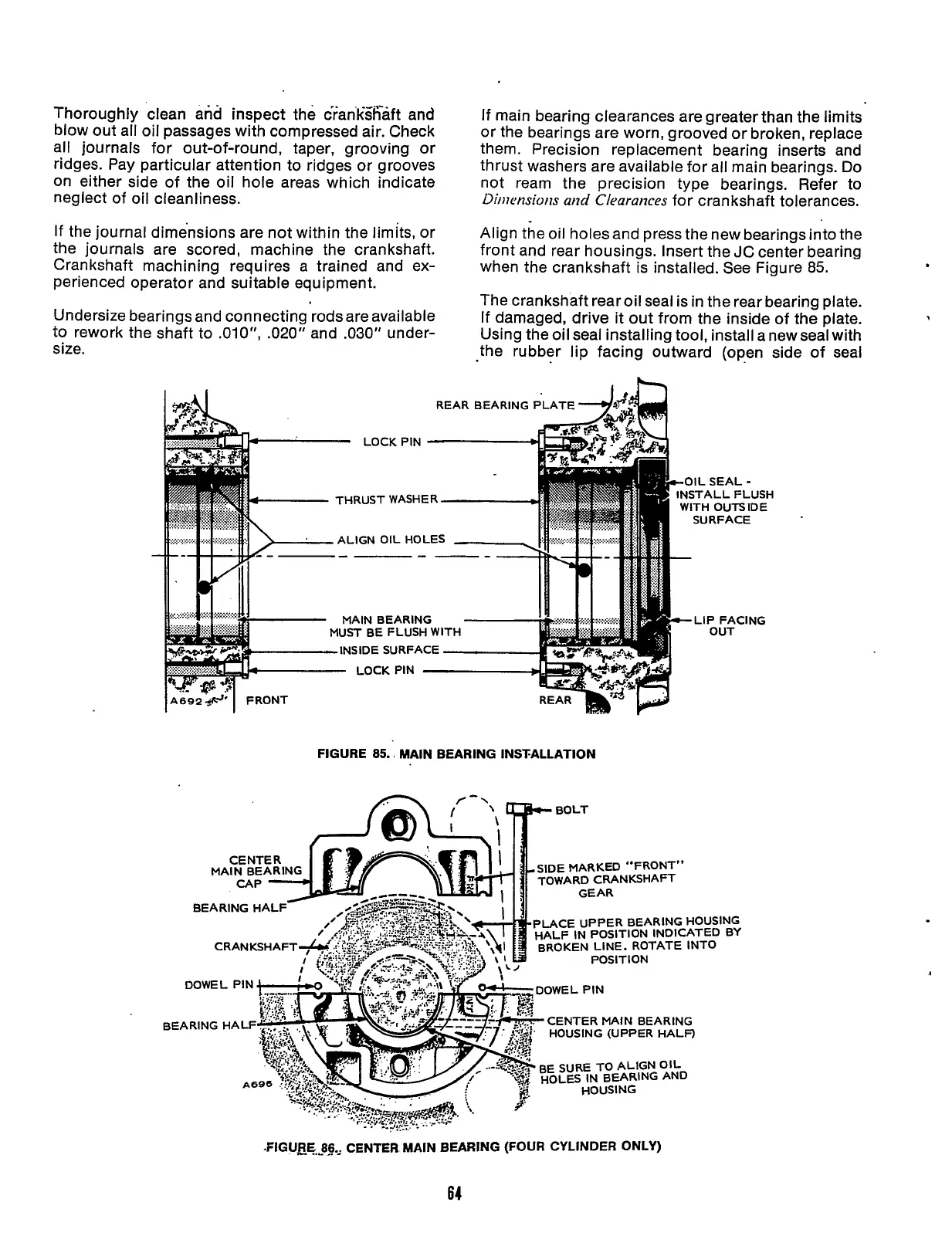

SIDE MARKED “FRONT”

TOWARD CRANKSHAFT

BEARING HALF

PLACE UPPER BEARING HOUSING

HALF IN POSITION INDICATED BY

CRANKSHAFT BROKEN LINE. ROTATE INTO

POSITION

BEARING HALF CENTER MAIN BEARING

HOUSING (UPPER HALF)

BE

SURE TO ALIGN OIL

HOLES

IN

BEARING AND

,

*FIGuRE,j6, CENTER MAIN BEARING (FOUR CYLINDER ONLY)

64

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...