OIL

PRESSURE GAUGE

The gauge is located on the lower front corner of the

cylinder block. If it is damaged, replace

it.

Before

replacing, check for a clogged oil passage behind the

gauge.

OIL

PUMP

The oil pump is mounted on the front of the crankcase

behind the gear cover and is driven by the crankshaft

gear.

Removal:

1.

Remove the gear cover and oil base (refer to

Engine

Repair

section). Unscrew the intake cup

from the pump.

2.

Remove the crankshaft lock ring and gear retain-

ing washer.

3. Loosen the two capscrews holding the pump to

the crankcase and remove the pump.

Repair:

Except for the gaskets, component parts of

the pump are not individually available. If the pump is

defective or worn, replace it. Disassemble the pump

by removing the two capscrews holding the pump

cover to the body. Inspect for excessive wear in gears

and shafts. To improve pump performance, adjust the

gear end clearance by using the thinnest gasket that

permits free movement of the pump shaft. Oil all parts

when reassembling the pump.

Installation:

Before installing, fill the pump intake and

outlet with oil. Mount the pump on the engine and

adjust for .005-inch lash between the pump gear and

the crankshaft gear. Mount the intake cup on the

pump

so

it

is parallel with the bottom of the

crankcase.

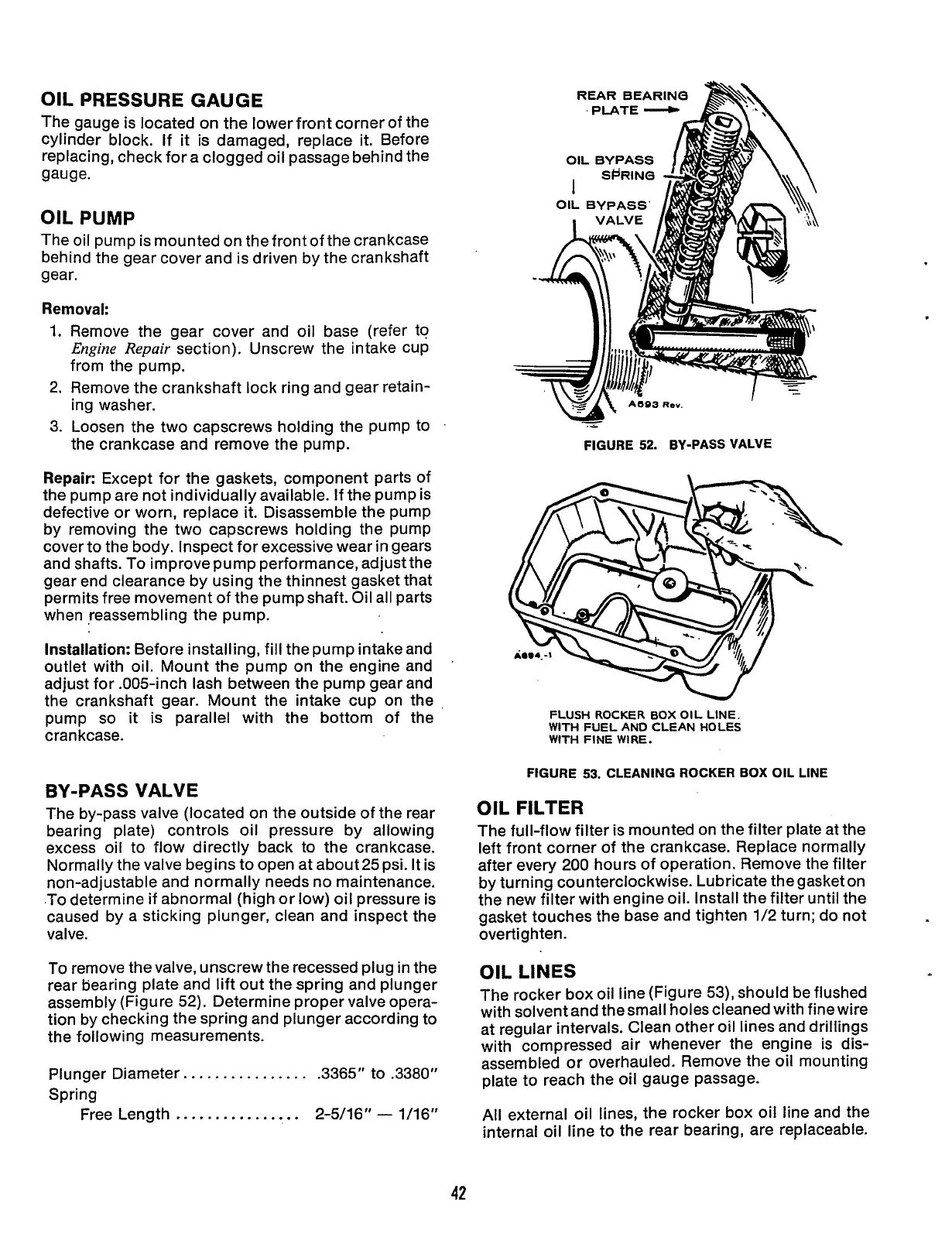

BY-PASS

VALVE

The by-pass valve (located on the outside of the rear

bearing plate) controls oil pressure by allowing

excess oil to flow directly back to the crankcase.

Normally the valve begins to open at about

25

psi. It is

non-adjustable and normally needs no maintenance.

To

determine

if

abnormal (high or low) oil pressure is

caused by a sticking plunger, clean and inspect the

valve.

To

remove the valve, unscrew the recessed plug in the

rear bearing plate and lift out the spring and plunger

assembly (Figure

52).

Determine proper valve opera-

tion by checking the spring and plunger according to

the following measurements.

Plunger Diameter.

. .

.

. . . .

.

. .

.

.

.

.

.

.3365" to .3380"

Spring

Free Length

,

. .

.

.

.

.

. .

.

.

. .

. . .

2-5/16"

-

1/16"

OIL

BYPASS

.i

FIGURE

52.

BY-PASS VALVE

W

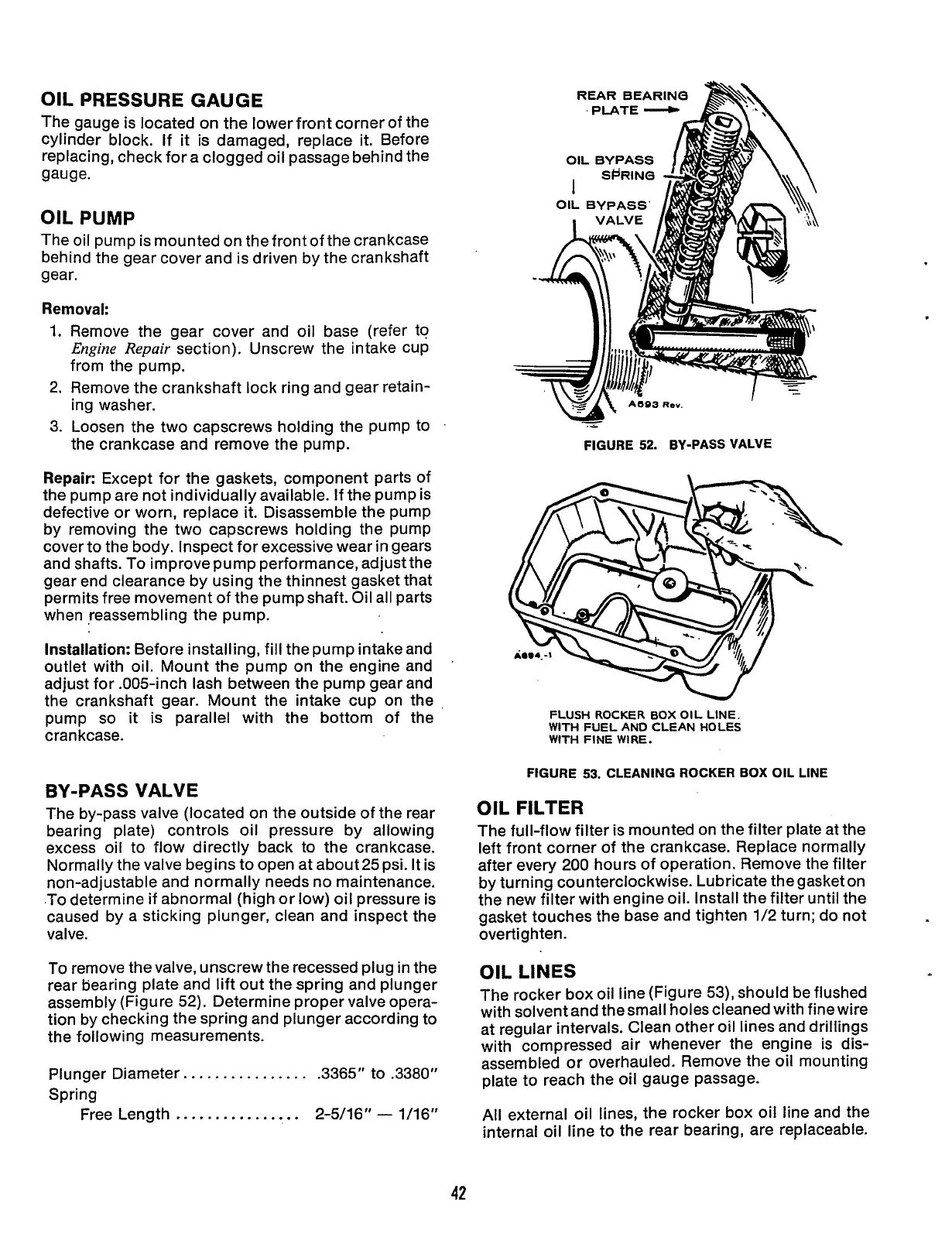

FLUSH

ROCKER

BOX

OIL LINE.

WITH FUEL AND CLEAN HOLES

WITH FINE WIRE.

FIGURE

53.

CLEANING ROCKER BOX OIL LINE

OIL

FILTER

The full-flow filter is mounted on the filter plate at the

left front corner of the crankcase. Replace normally

after every

200

hours of operation. Remove the filter

by turning counterclockwise. Lubricate the gasket on

the new filter with engine oil. Install the filter until the

gasket touches the base and tighten

1/2

turn; do not

overtighten.

OIL

LINES

The rocker box oil line (Figure

53),

should be flushed

with solvent and thesmall holes cleaned with finewire

at regular intervals. Clean other oil lines and drillings

with compressed air whenever the engine is dis-

assembled or overhauled. Remove the oil mounting

plate to reach the oil gauge passage.

All external oil lines, the rocker box oil line and the

internal oil line to the rear bearing, are replaceable.

42

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...