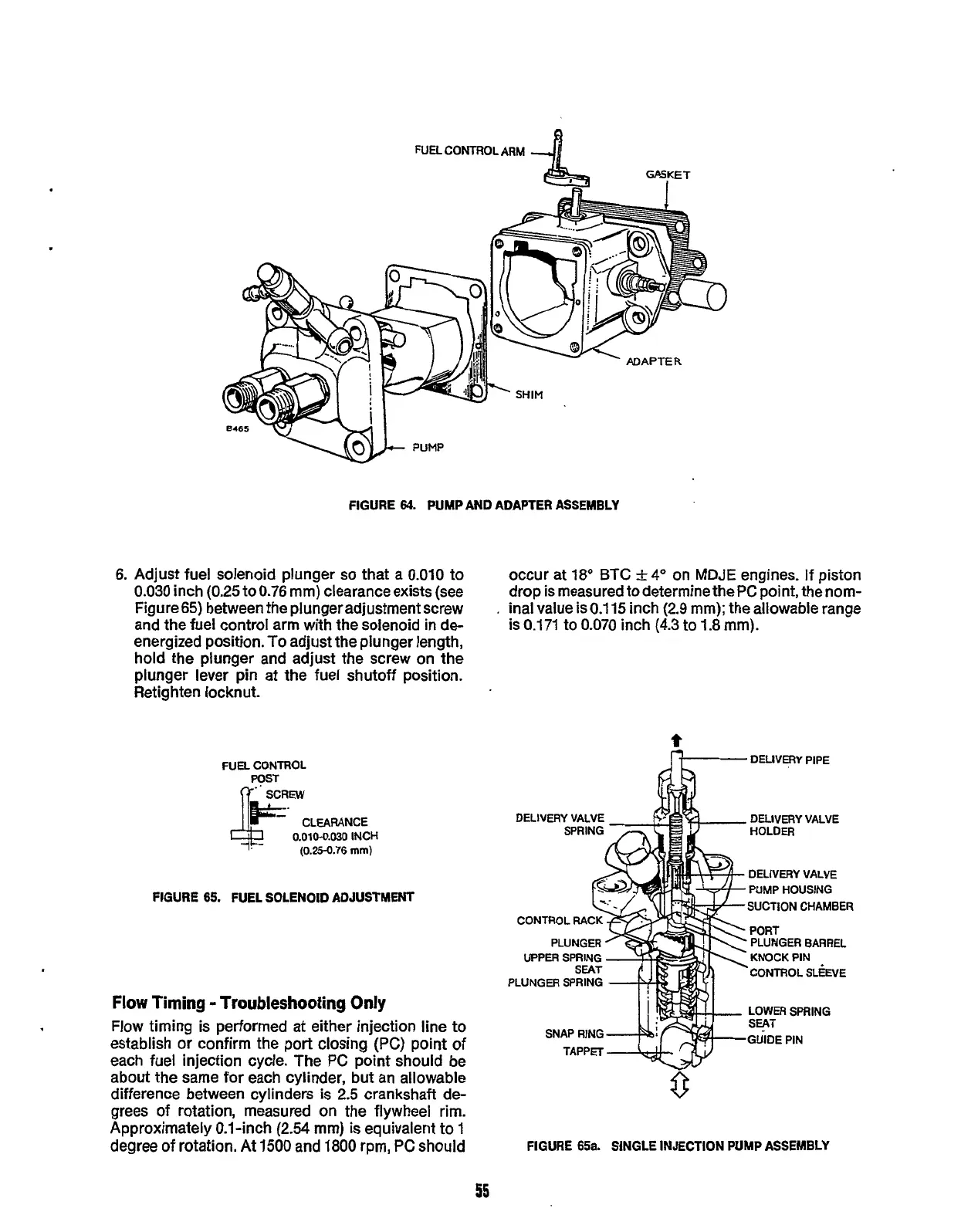

FIGURE

64.

PUMP AND ADAPTER

ASSEMBLY

6.

Adjust fuel solenoid plunger

so

that a

0.010

to

0.030

inch

(0.25

to 0.76 mm) clearance exists (see

Figure65) between the plunger adjustment screw

and the fuel control arm with the solenoid

in

de-

energized position.

To

adjust the plunger length,

hold the plunger and adjust the screw on the

plunger lever pin at the fuel shutoff position.

Retighten locknut.

occur at 18"

BTC

+4"

on

MDJE

engines. If piston

drop is measured to determine the PC point, the nom-

.

inal value is

0.1

15

inch (2.9 mm); the allowable range

is 0.171 to 0.070 inch

(4.3

to 1.8 mm).

FUEL

CONTROL

CLEARANCE

0.010-0.030

INCH

(0.25-0.76

mm)

FIGURE

65.

FUEL SOLENOID ADJUSTYEW

Flow

Timing

-

Troubleshooting Only

Flow timing is performed at either injection line to

establish

or

confirm the port closing (PC) point

of

each fuel injection cycle. The PC point should be

about

the

same for each cylinder, but an allowable

difference between cylinders is

2.5

crankshaft

de-

grees of rotation, measured

on

the flywheel rim.

Approximately 0.1-inch

(2.54

mm)

is

equivalent to

1

degree

of

rotation.

At

1500

and

1800

rpm, PC should

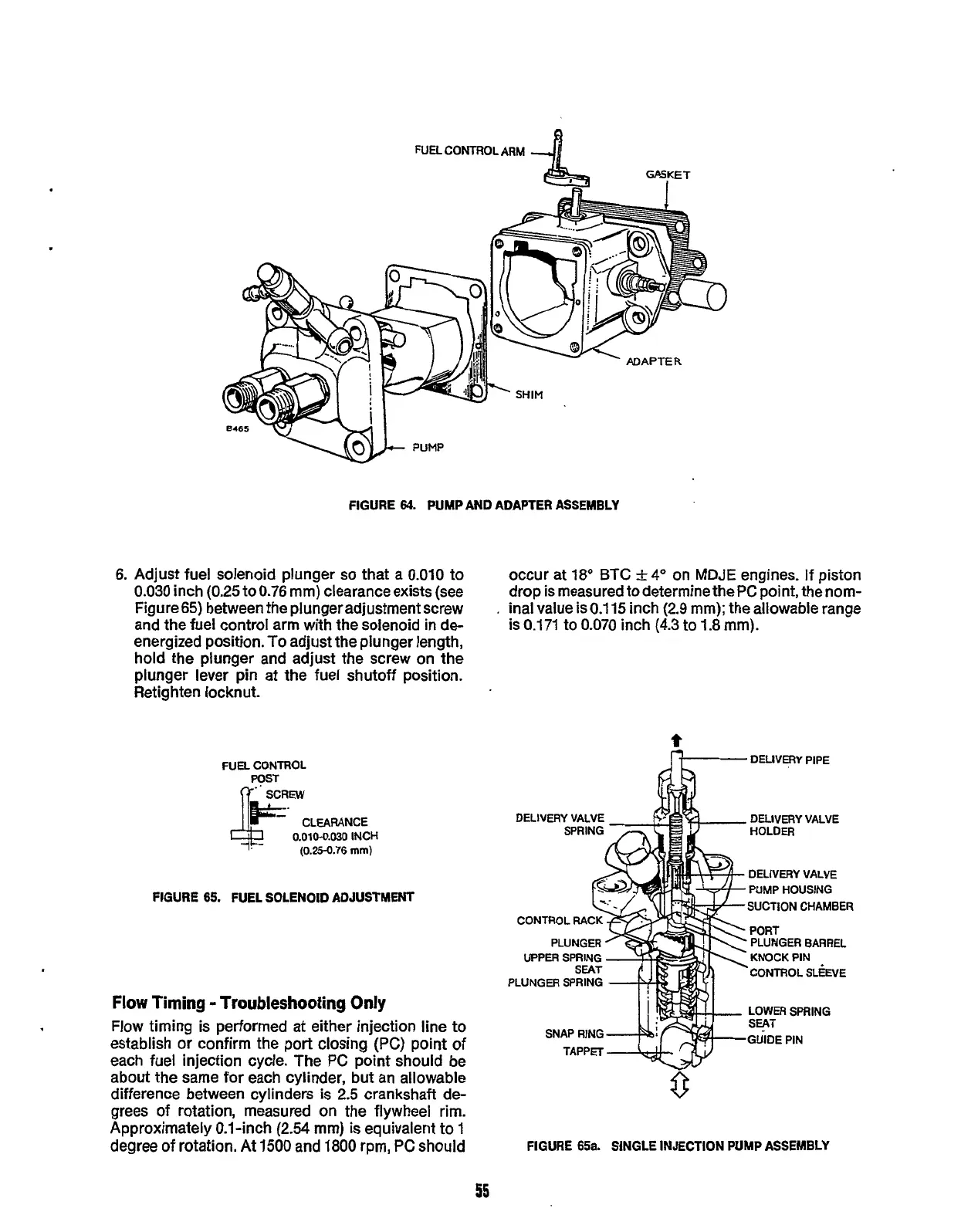

t

DELIVERY

PIPE

DELIVERY VALVE

DELIVERY

VALVE

HOLDER

DELIVERY

VALVE

PUMP

HOUSING

SUCTION

CHAMBER

PORT

PLUNGER BARREL

KNOCK

PIN

UPPER

SPRING

PLUNGER

SPRING

CONTROL

SL&E

LOWER

SPRING

SEAT

GUIDE

PIN

FIGURE

65a.

SINGLE INJECTION PUMP ASSEMBLY

55

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...