Flow

Timing Procedure

To

determine PC, proceed as follows:

1.

Remove one high pressure line (both ends), and

the corresponding delivery valve holder, spring,

volume reducer, and delivery valve, Figure 65a.

Leave gasket and seat in pump.

Place the spring and volume reducer in a clean container

of

fuel until re-installed.

2. Re-install delivery valve holder (without spring

and volume reducer).

3.

Install high pressure line

on

delivery valve outlet

so

that drops of fuel can be easily counted and

collected in a receptacle at the open end

of

the

line.

4.

Move the fuel control arm toward the front of the

engine to full fuel range.

The fuel solenoid must be energized or held (blocked) to keep

the plunger

out

of the way.

5.

Manually operate transfer pump lever to provide

fuel pressure to injection pump.

6. Rotate flywheel clockwise very slowly by hand

until fuel stops flowing from open line, even

though transfer pump operation is continued.

7. Rotate flywheel counterclockwise until fuel flows

freely; then, clockwise very slowly to position

where fuel drops can be counted at one drop per

second with the transfer pump operating.

This is the PC point;

it

should be marked on the flywheel

opposite the timing pointer.

8.

After flow timing iscompleted, remove high pres-

sure line and delivery valve holder; then, reinstall

delivery valve, spring, and volume reducer.

Make sure all parts are

clean.

9. Reinstall delivery valve holder and torque Bryce

holder to 29 to 33 ft.-lb. (39 to

44 Nm). Torque

Kiki holder to

44

to 47 ft.-lb.

(60-64

Nm). If fuel

leakage occurs, replace the delivery valve gasket.

10.

Reinstall high pressure line between pump and

nozzle.

11.

Using the same procedure, flow timing can be

performed on the other cylinder to determine PC

or the difference in degrees between cylinders;

2.5 degrees is allowable.

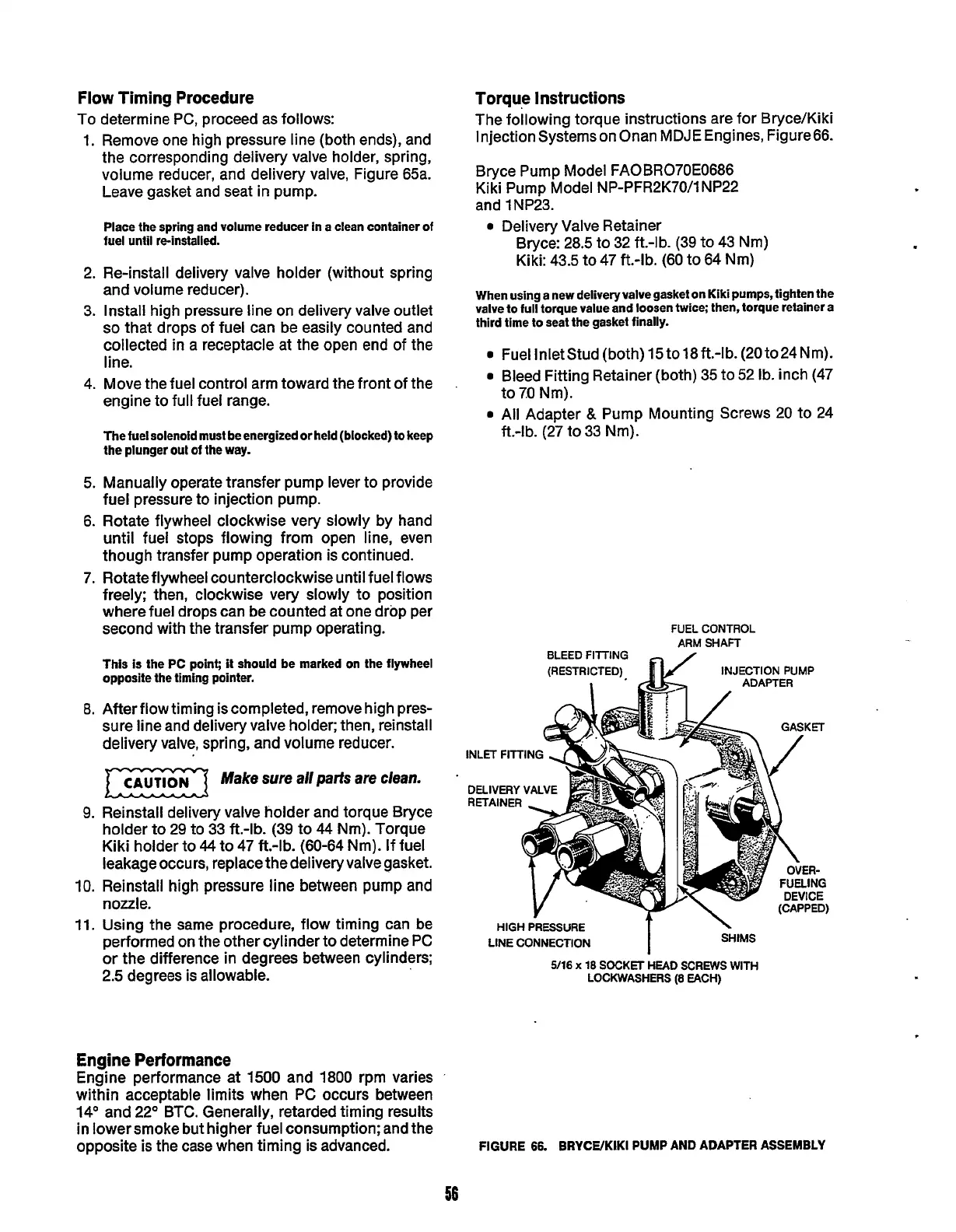

Torque Instructions

The following torque instructions are for Bryce/Kiki

Injection Systemson Onan MDJE Engines, Figure66.

Bryce Pump Model FAOBR070E0686

Kiki Pump Model NP-PFR2K70/1NP22

and

1

NP23.

0

Delivery Valve Retainer

Bryce: 28.5 to 32 ft.-lb. (39 to 43 Nm)

Kiki: 43.5 to 47 ft.-lb. (60 to 64 Nm)

When using a new deliveryvalvegasket

on

Kiki

pumps,

tighten the

valve

lo

full torque value and loosen twice; then, torque retainer a

third time to seat the gasket finally.

0

Fuel Inletstud (both)

15

to18ft.-lb. (20to24Nm).

0

Bleed Fitting Retainer (both) 35 to 52 Ib. inch (47

0

All

Adapter

&

Pump Mounting Screws 20 to 24

to

7.0

Nm).

ft.-lb. (27 to 33 Nm).

FUEL

CONTROL

ARM

SHAFT

BLEED

FITTING

(RESTRICTED)

fl/

INJECTION

PUMP

INLET FITTING

DELIVERY

VALVE

RETAINER

SHIMS

T

HIGH

PRESSURE

LINE

CONNECTION

5/16

x

18

SOCKET

HEAD

SCREWS

WITH

LOCKWASHERS

(8

EACH)

Engine Performance

Engine performance

at

1500

and 1800 rpm varies

within acceptable limits when

PC

occurs between

14' and 22' BTC. Generally, retarded timing results

in lower smoke but higher fuel consumption; and the

opposite is the case when timing is advanced.

FIGURE

66.

BRYCWKIKI

PUMP AND ADAPTER ASSEMBLY

56

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...