MARINE WATER PUMPS

Two types of marine water pumps are in general use:

the metal impeller pump and

the

neoprene impeller

pump. Each pump has certain advantages and dis-

advantages (see Table

3)

and both are used exten-

sively with marine cooling systems. Two types of

pumps are necessary because water pumps are used

to perform different functions, depending on the type

of cooling system and the operating conditions.

Metal impeller pumps provide no suction lift but can

operate in hot, cold, or dirty water. Neoprene impeller

pumps provide a suction

lift,

but can be used only

with clean, cool water.

The metal impeller pumps are used for captive water

systems, and the neoprene impeller pumps are used

for sea water systems.

All

captive water system

pumps (metal impeller) are driven by

a

V-belt from

the engine crankchaft.

All

sea water pumps (neo-

prene impeller) for the J-series (except

MDJE,

Spec

AB)

are gear driven.

Captive Water Pump

Periodically check the captive water pump forwear or

signsof leakage from theshaft seal. Loosen thedrive

belt and move the water pump pulley back and forth.

The pulley should be tight on the shaft and

only

a

slight amount of bearing play should be felt. Rebuild

the pump if wear is excessive or if the seal leaks. Refer

to the section on

Water

Pumps

for water pumps

service procedures.

Sea Water

Pump

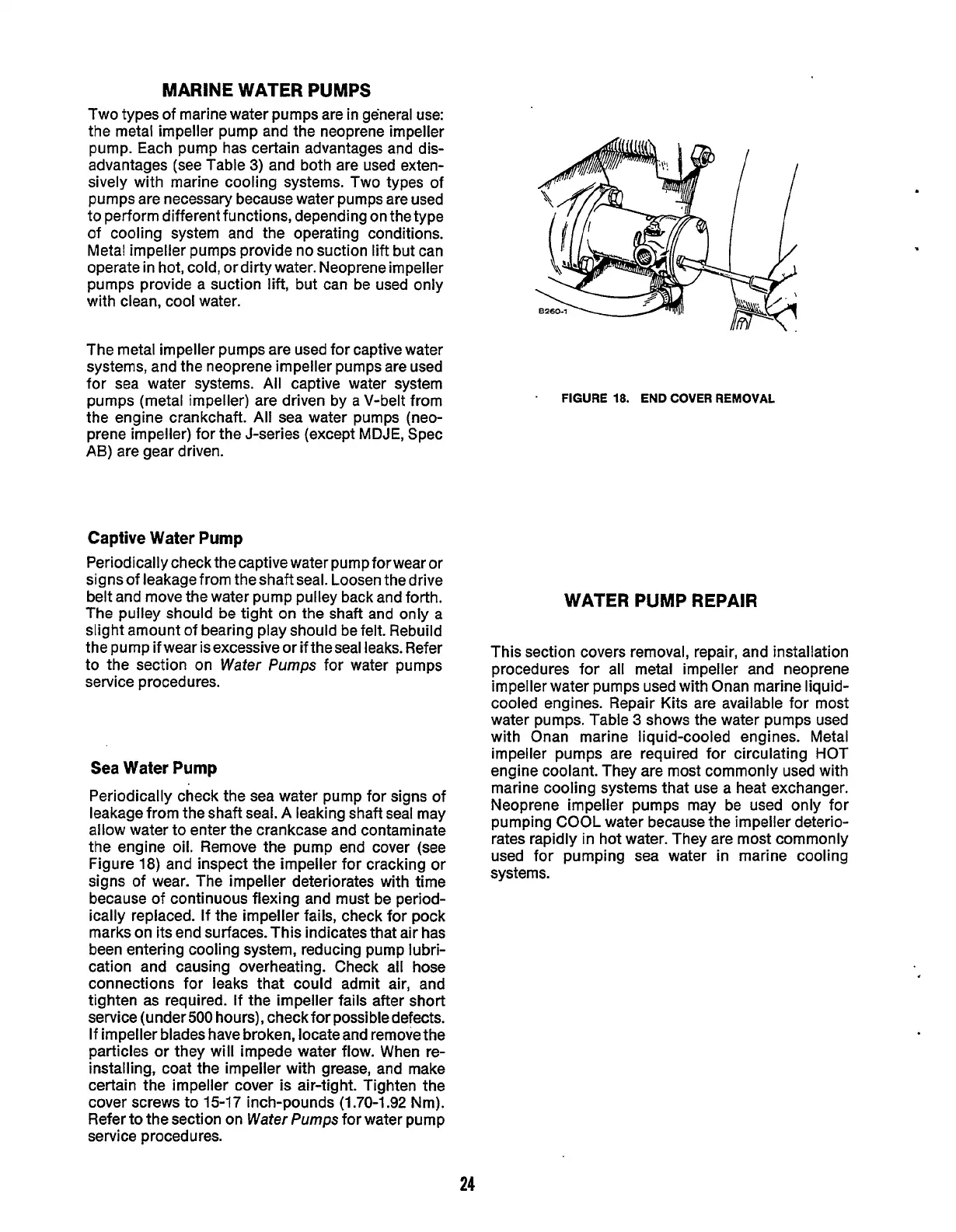

Periodically check the sea water pump for signs of

leakage from the shaft seal.

A

leaking shaft seal may

allow water to enter the crankcase and contaminate

the engine oil. Remove the pump end cover (see

Figure

18)

and inspect the impeller for cracking or

signs

of

wear. The impeller deteriorates with time

because of continuous flexing and must be period-

ically replaced. If the impeller fails, check for pock

marks on its end surfaces. This indicates that air has

been entering cooling system, reducing pump lubri-

cation and causing overheating. Check

all hose

connections for leaks that could admit air, and

tighten

as

required. If

the

impeller fails after short

service (under500 hours),

checkforpossibledefects.

If impeller blades have broken, locate and remove the

particles or they will impede water flow. When re-

installing, coat the impeller with grease, and make

certain the impeller cover is air-tight. Tighten the

cover screws to 15-17 inch-pounds (1.70-1.92 Nm).

Refer to the section on

Water

Pumps

for water pump

service procedures.

FIGURE

18.

END

COVER

REMOVAL

WATER PUMP REPAIR

This section covers removal, repair, and installation

procedures for all metal impeller and neoprene

impeller water pumps used with Onan marine liquid-

cooled engines. Repair Kits are available for most

water pumps. Table

3

shows the water pumps used

with Onan marine liquid-cooled engines. Metal

impeller pumps are required for circulating HOT

engine coolant. They are most commonly used with

marine cooling systems that use a heat exchanger.

Neoprene impeller pumps may be used only for

pumping

COOL water because the impeller deterio-

rates rapidly

in

hot water. They are most commonly

used for pumping sea water in marine cooling

systems.

24

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...